Inflammatory factor adsorbing agent for blood perfusion and preparation method

A technology of inflammatory factors and adsorbents, which is applied in the field of inflammatory factor adsorbents and preparations, can solve the problems of general removal of inflammatory factors, poor blood compatibility, and human hazards of coating materials, so as to improve hydrophilicity , Improve skin symptoms, good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

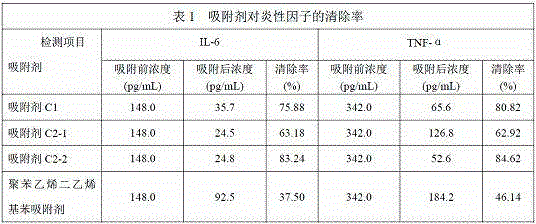

Examples

Embodiment 1

[0035] polymethyl methacrylate adsorbent

[0036] 1-1 Amination reaction

[0037] Take polymethyl methacrylate (PMMA) resin microspheres (pore diameter 5-50nm, specific surface area greater than 500m 2 / g) Add 10mL of dichloroethane to 10g and soak overnight, then add 10mL of 50% hexamethylenediamine in dimethylformamide solution, stir and react at 130°C for 10 hours at 200rpm. After the reaction was completed, the resin microspheres were washed with alcohol and purified water respectively.

[0038] 1-2 Condensation reaction with cysteine

[0039] Take the resin microspheres obtained in 1-1, add 20mL of 1% cysteine solution, adjust the pH to 4.8, add 0.8g NHS (N-hydroxysuccinimide), and then slowly add 0.4g 1-(3 -Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), shaking and reacting at 25°C for 4 hours. After the reaction was completed, the resin was washed with alcohol and purified water respectively.

[0040] 1-3 Acetylation reaction

[0041] Take the r...

Embodiment 2

[0043] Polystyrene divinylbenzene resin adsorbent

[0044] 2-1 Epoxidation pretreatment

[0045] Take 10g of polystyrene divinylbenzene resin microspheres (pore diameter 5-50nm, specific surface area not less than 500m 2 / g, cross-linking agent divinylbenzene purity 80%) add 40mL dichloroethane to soak overnight, add 20mL 1% m-chloroperoxybenzoic acid acetone solution drop by drop, place in an ice-water bath (temperature controlled at 2°C ) stirring reaction for 24 hours at a speed of 200 rpm. After the reaction was completed, the resin microspheres were washed with alcohol and purified water respectively.

[0046] 2-2 Amination reaction

[0047] Take 2-1 resin, add 30mL of 2% hexamethylenediamine aqueous solution, shake and react at 60°C for 24 hours. After the reaction was completed, the resin microspheres were washed with alcohol and purified water respectively.

[0048] 2-3 Condensation reaction with cysteine

[0049]Take the resin obtained in 2-2, add 20mL of 1.2%...

Embodiment 3

[0053] Cellulose microsphere carrier adsorbent

[0054] Take 10mL of cellulose microspheres, add 20mL of 5% epichlorohydrin, and shake at 40°C for 4 hours. After washing, add 30mL of 2% ethylenediamine aqueous solution, and shake and react at 60°C for 24 hours. After the reaction was completed, the cellulose microspheres were washed with alcohol and purified water respectively. Next, add 20mL of 1.2% cysteine solution, adjust the pH to 4.8, add 0.5g NHS (N-hydroxysuccinimide), and then slowly add 0.4g 1-(3-dimethylaminopropyl)- 3-Ethylcarbodiimide hydrochloride (EDC), shaking reaction at 25°C for 5 hours. After the reaction was completed, the cellulose microspheres were washed with alcohol and purified water respectively. After drying, 20 mL of 6% acetyl chloride and triethylamine in dimethylformamide were added dropwise and reacted with shaking at 30°C for 2 hours. After the reaction was completed, the cellulose microspheres were washed with alcohol and purified water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com