Nano-tungsten oxide, one-step vapor phase reduction preparation method of nano-tungsten oxide and application of nano-tungsten oxide

A technology of tungsten oxide and oxide, which is applied in the direction of nanotechnology, nanotechnology, tungsten oxide/tungsten hydroxide, etc., can solve the problems of unachievable promotion, increased energy consumption, and scarce reserves, etc., and achieves easy application, simple operation, The effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1, preparation of tungsten oxide

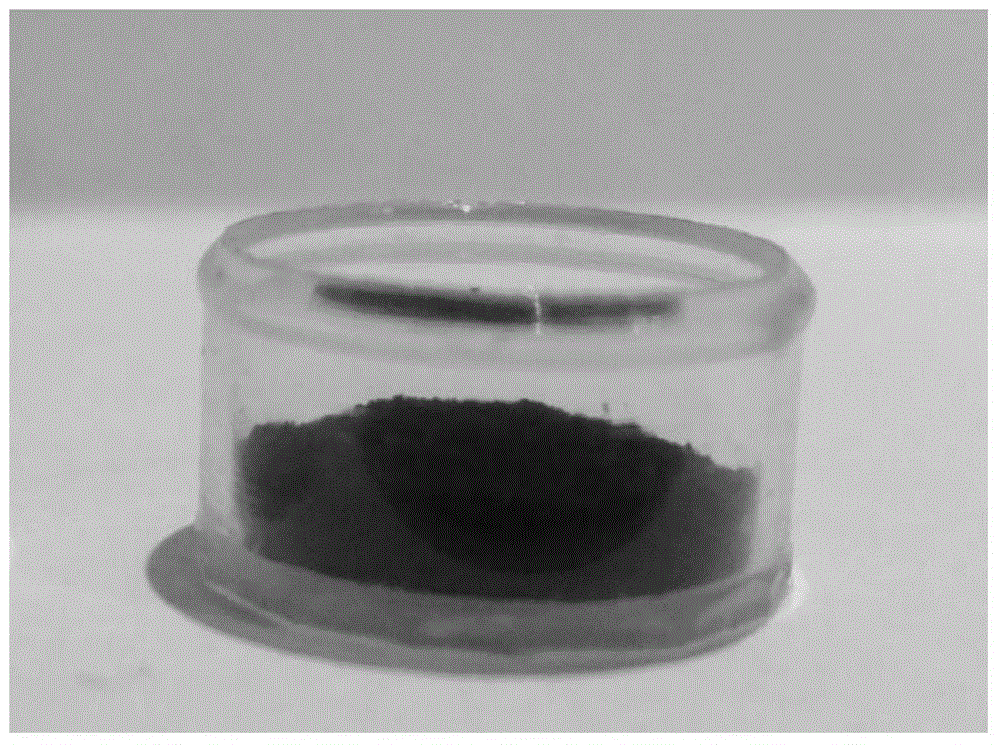

[0034] 1.0g WO 3 Disperse in 35mL of absolute ethanol and ball mill for 24 hours, put the ball milled powder into the quartz ark; push the quartz ark into the central hot zone of the tube furnace, and seal the flange; pass the hydrogen and argon through the rotameter After metering (hydrogen gas flow rate is 0.01L / min, argon gas flow rate is 0.09L / min) fully mixed and then enters the tube furnace; the temperature of the tube furnace is raised to 500 °C at a rate of 5 °C / min, and the temperature is treated for 30 min; then, Naturally cool to room temperature, take out the quartz ark, wash the contents of the ark several times with distilled water and absolute ethanol, and dry the product in an oven at 60°C for 3 hours to obtain nano-sized tungsten oxide powder.

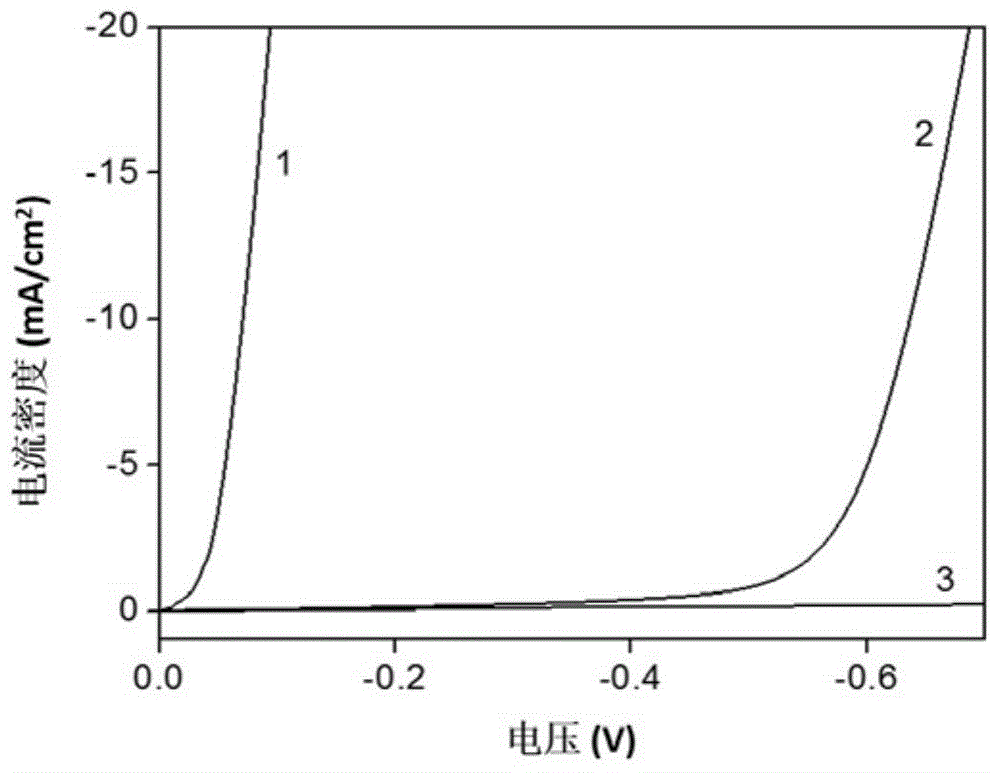

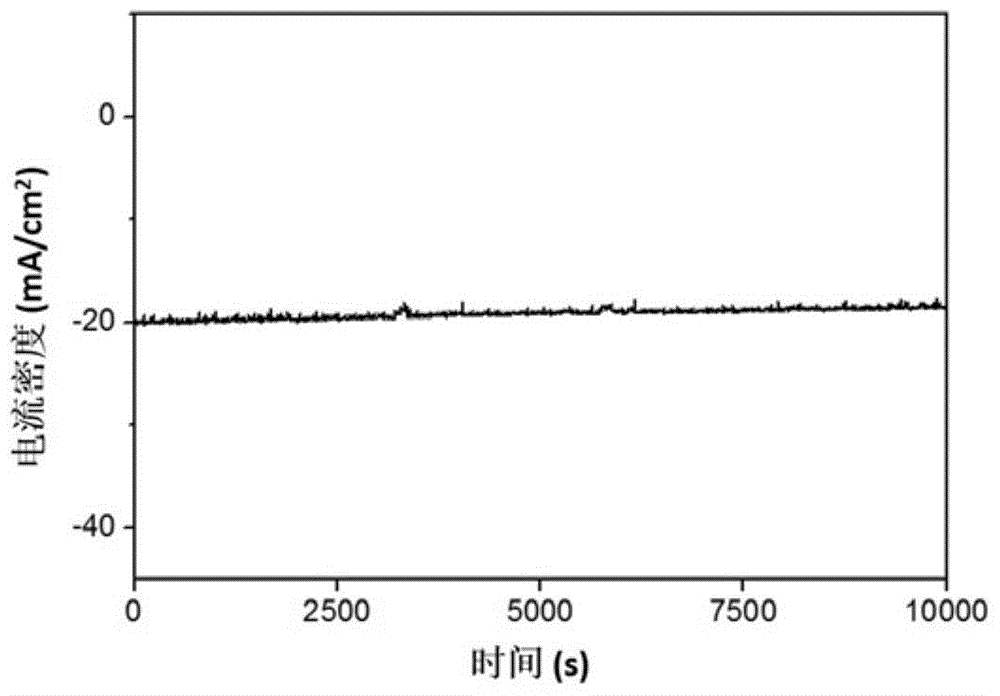

[0035] Step 2. Performance Characterization Test

[0036] Disperse 0.02mg of tungsten oxide powder in a mixed solvent of water and ethanol containing Nafion solution to ...

Embodiment 2

[0049] 0.5g WO 3 Disperse in 10mL of absolute ethanol and ball mill for 48 hours, put the ball-milled powder into the quartz ark; push the quartz ark into the central hot zone of the tube furnace, and seal the flange; pass the hydrogen and argon through the rotameter After metering (hydrogen gas flow rate is 0.03L / min, argon gas flow rate is 0.27L / min) and fully mixed, enter the tube furnace; heat the tube furnace to 300 °C at a rate of 5 °C / min, and treat at constant temperature for 60 min; then, Naturally cool to room temperature, take out the quartz ark, wash the contents of the ark several times with distilled water and absolute ethanol, and dry at 100°C for 1 hour to obtain nano-sized tungsten oxide powder. Features and properties are similar to Example 1.

Embodiment 3

[0051] 2.0g WO 3 Disperse in 50mL of absolute ethanol and ball mill for 1 hour, put the ball-milled powder into the quartz ark; push the quartz ark into the central hot zone of the tube furnace, and seal the flange; pass the hydrogen and argon through the rotameter After metering (hydrogen gas flow rate is 0.005L / min, argon gas flow rate is 0.045L / min) fully mixed and then enters the tube furnace; the temperature of the tube furnace is raised to 600 °C at a rate of 5 °C / min, and the constant temperature is treated for 120 min; then, Naturally cool to room temperature, take out the quartz ark, wash the contents of the ark several times with distilled water and absolute ethanol, and dry at 100°C for 1 hour to obtain nano-sized tungsten oxide powder. Features and properties are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com