Controlled-release efficacy-improved biological fertilizer and preparation method thereof

A bio-fertilizer and slow-release technology, applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problems of lack of abundant voids and high cost, reduce the occurrence of crop diseases and insect pests, improve air permeability, and promote plant growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 10 parts of urea, 2 parts of calcium ammonium nitrate, 10 parts of potassium nitrate, 4 parts of potassium carbonate, 4 parts of ammonium nitrate phosphate, 2 parts of phosphate rock powder, 2 parts of diammonium phosphate, 3 parts of heavy superphosphate, 8 parts of chloride Potassium, 10 parts potassium sulfate, 3 parts ammonium chloride, 3 parts ammonium sulfate, 0.5 parts magnesium sulfate, 0.5 parts zinc sulfate, 0.5 parts ferrous sulfate, 0.5 parts boric acid, 0.5 parts borax, 0.5 parts copper sulfate, 0.5 parts molybdenum Ammonium bicarbonate, 2 parts of DMPP, 2 parts of N-butyl thiophosphoramide, 1.5 parts of Penicillium bilaii and 5 parts of humus soil were evenly mixed, granulated and dried, measured and packaged to obtain the fertilizer of the present invention.

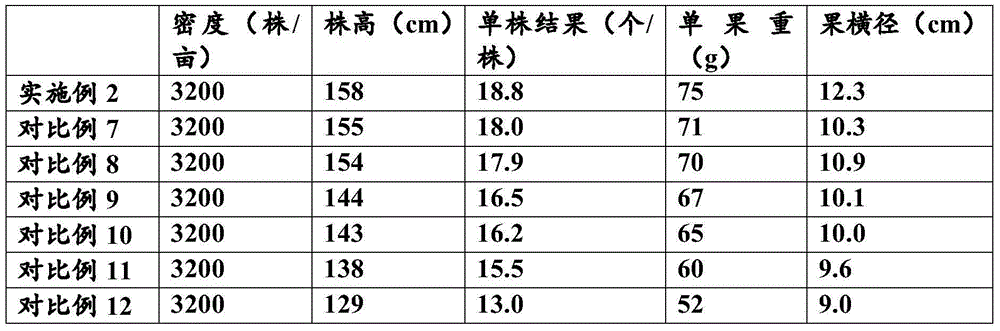

Embodiment 2

[0054] 25 parts of urea, 3 parts of calcium ammonium nitrate, 2 parts of steel slag phosphate fertilizer, 4 parts of heavy superphosphate, 10 parts of potassium sulfate, 4 parts of ammonium sulfate, 1 part of magnesium sulfate, 1 part of zinc sulfate, 1 part of ferrous sulfate, 1 1 part of boric acid, 1 part of borax, 1 part of copper sulfate, 1 part of ammonium molybdate, 1.5 parts of DMPP, 3 parts of N-butylthiophosphoric triamide, 0.7 part of Penicillium bilaii and 3 parts of humus soil, mixed evenly, granulated and baked Dry, metered and packaged to obtain the fertilizer of the present invention.

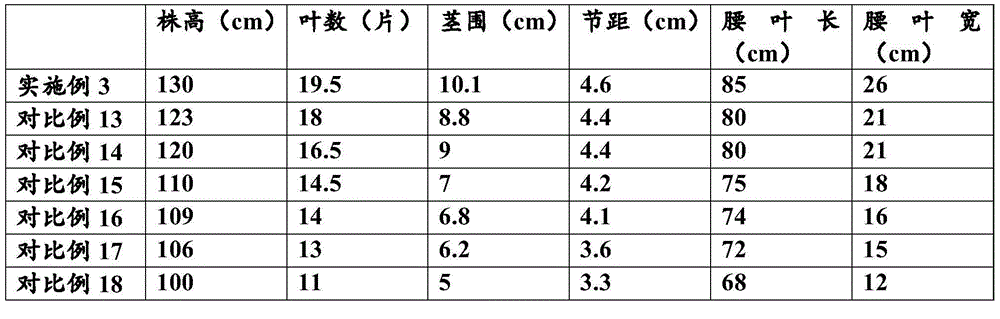

Embodiment 3

[0078] 10 parts of urea, 2 parts of calcium ammonium nitrate, 3 parts of potassium nitrate, 4 parts of potassium carbonate, 4 parts of ammonium nitrate phosphate, 3 parts of calcium magnesium phosphate fertilizer, 2 parts of diammonium phosphate, 3 parts of heavy superphosphate, 2 parts of chloride Potassium, 4 parts potassium sulfate, 3 parts ammonium chloride, 3 parts ammonium sulfate, 0.5 parts magnesium sulfate, 0.5 parts zinc sulfate, 0.5 parts ferrous sulfate, 0.5 parts boric acid, 0.5 parts borax, 0.5 parts copper sulfate, 0.5 parts molybdenum Ammonium bicarbonate, 10 parts of organic carbon, 0.7 part of Penicillium bilaii and 2.5 parts of humus soil were pulverized, sprayed with 2 parts of wood vinegar and uniformly mixed, granulated and dried, and measured and packaged to obtain the fertilizer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com