Multiwalled carbon nanotube and graphene reinforced modified regenerated protein fiber and preparation method thereof

A technology of multi-walled carbon nanotubes and protein regeneration, applied in the direction of single-component protein rayon, fiber chemical characteristics, rayon manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of carboxylated multi-walled carbon nanotubes is as follows:

[0034] Multi-walled carbon nanotubes (5.0 g), p-aminobenzoic acid (5.0 g) and polyphosphoric acid (200.0 g) were placed in a 500 mL three-neck flask, mechanically stirred at 130 °C for 3 h, and then P 2 o 5 (50.0g), mechanically stirred at 130°C for 72h, under nitrogen protection. The obtained product was repeatedly washed and filtered with distilled water and ammonia water, and the product was extracted with distilled water and anhydrous methanol for three days each to remove unnecessary reactants and impurities, and then vacuum-dried to obtain carboxylated multi-walled carbon nanotubes.

[0035] The above method is only the preparation method of graphene oxide, carboxylated graphene, and carboxylated multi-walled carbon nanotubes described in specific experiments, and those skilled in the art can prepare products based on this, and can also be based on the prior art at the same time...

Embodiment 1

[0038] 8M urea with a mass ratio of 17:1 is mixed with wool, and the wool is completely immersed in the urea solution, maintained at 70°C, adding cysteine accounting for 10% of the wool mass, and adjusting the pH to 10. After 24 hours, centrifuge at a rate of 15000r / min for 20 minutes to remove undissolved wool residue, add hypochlorous acid and sodium sulfate solution with a pH of 3 to precipitate keratin, wash with deionized water, and centrifuge Three times, the keratin was collected, dried at 50° C., and then ball-milled into a 20-mesh micropowder to obtain wool keratin powder.

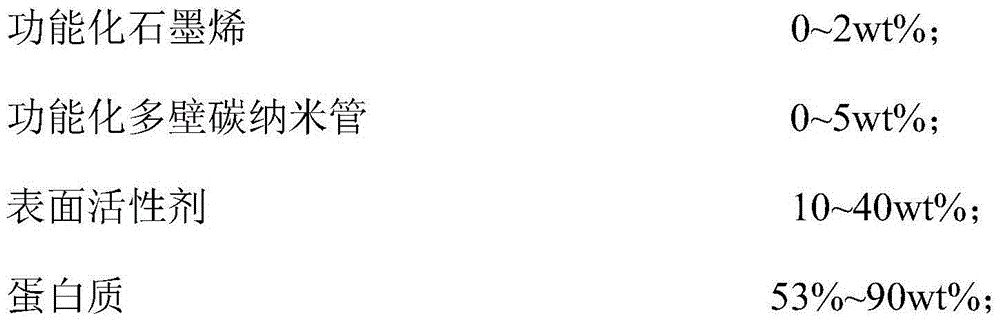

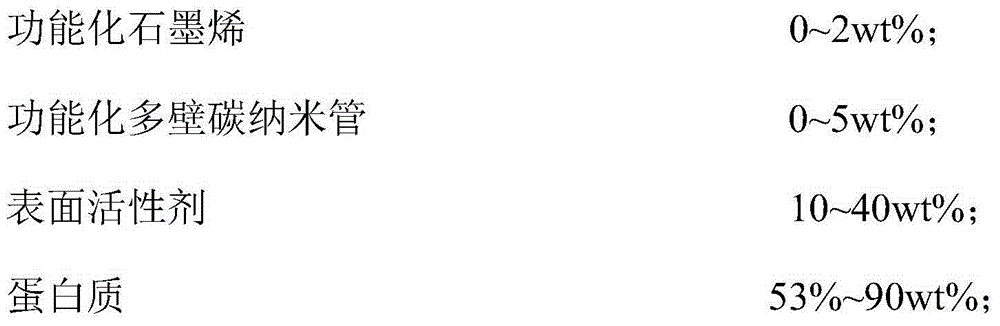

[0039] Add 89.5wt% wool keratin powder, 0.2wt% carboxylated graphene and 0.3wt% carboxylated multi-walled carbon nanotubes to 10wt% sodium lauryl sulfate in 0.3M sodium carbonate-sodium bicarbonate buffer solution (pH = 9.5), aging at 25°C for 24 hours to obtain a spinning stock solution; heat the spinning stock solution to 90°C for 1 hour, then extrude through a 0.1mm spinneret hole, and enter ...

Embodiment 2

[0041] 79.5wt% adopt the wool keratin micropowder prepared in Example 1, 0.1wt% aminated graphene and 0.4wt% carboxylated multi-walled carbon nanotubes to add the ammonium-ammonium chloride of 20wt% calcium lauryl sulfate In a buffer solution (pH 9), aging at 45°C for 10 hours to obtain a spinning stock solution; heating the spinning stock solution to 90°C for 1 hour, and then extruding through a 0.08mm spinneret hole into hot air at 120°C In the tunnel, after passing through the godet roll, it is drawn 2.8 times on a 150°C hot roll, and further dried and shaped by a 120°C hot roll to obtain the multi-walled carbon nanotubes and graphene-enhanced modified regenerated protein fibers. The diameter of the fiber is 15 μm, the tensile strength at break is 160 MPa, the Young's modulus is 0.9 GPa, and the elongation at break is 10%. The transmission electron microscope observation shows that the carbon nanotubes are basically oriented along the fiber axis; the scanning electron micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com