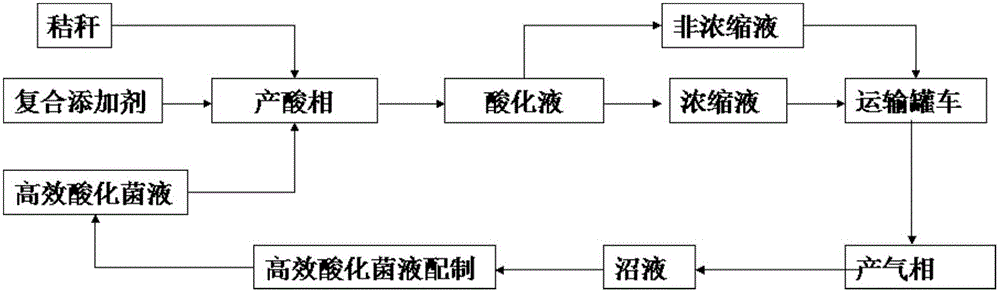

Method for preparing biogas through two-phase fermentation of crop stalks

A bio-natural gas and straw technology, applied in fermentation, waste fuel, etc., can solve the problems of poor gas quality and low bio-conversion rate of straw, and achieve the effects of reducing energy consumption, shortening processing time, and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0036] Following examples 1-11 and comparative example 1 volatile fatty acid (VFAs) content determination method are as follows: volatile fatty acid determination adopts gas chromatography to measure, use Stabil-Wax-DA30m*0.53mm*0.25m type capillary column, FID detects 4-methylpentanoic acid was used as internal standard with temperature programming. The quantitative analysis of the sample is determined by the size of the peak area, and the qualitative analysis of the sample is determined by the retention time. For specific methods, please refer to "Study on Optimization of Technical Parameters for Hydrolysis of Bundled Wheat Straw to Produce Acid" (Lv Lili, 2013).

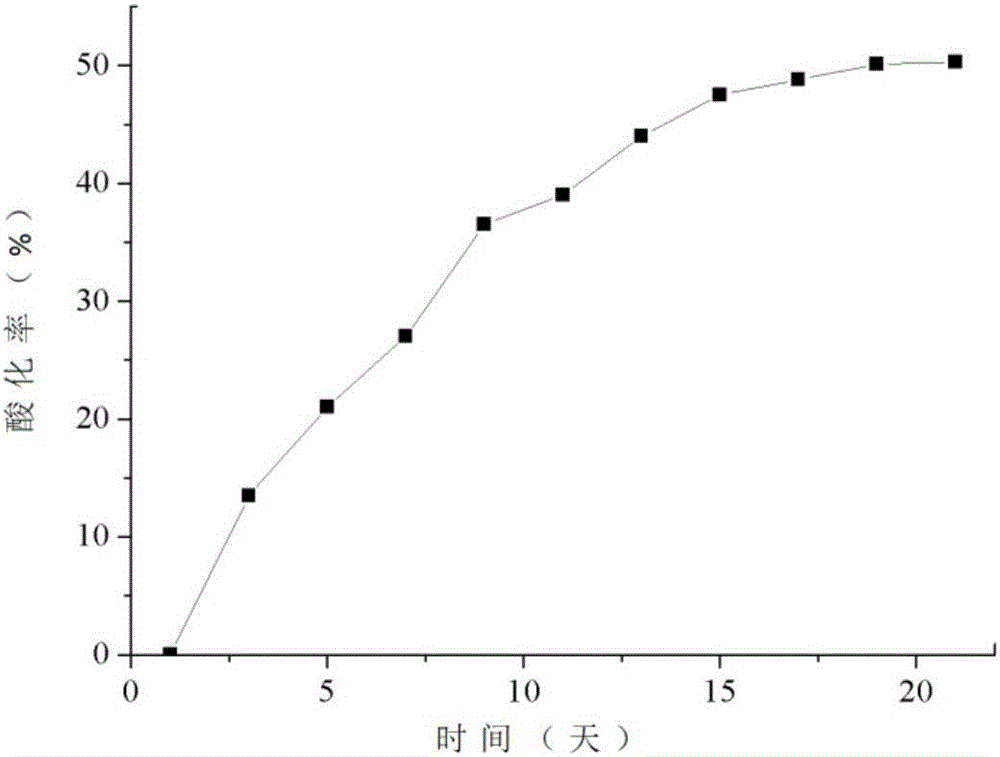

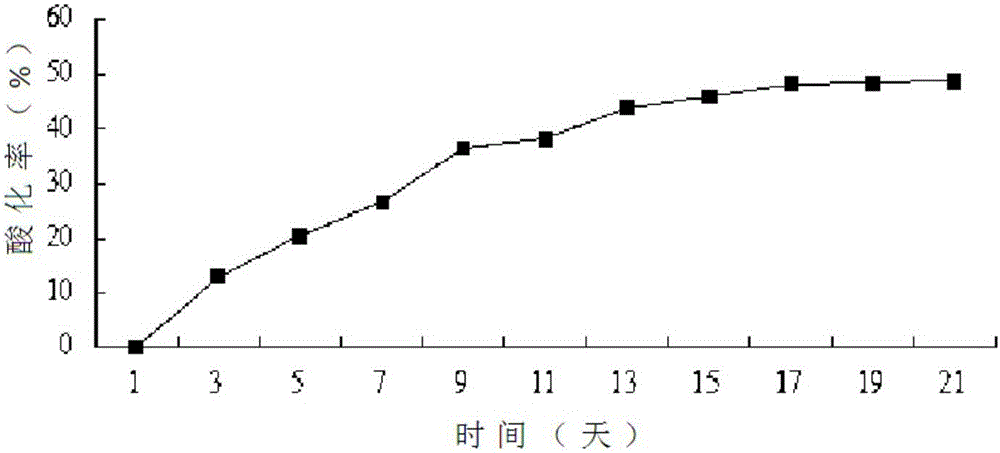

[0037] The calculation method of the acidification rate of the following examples 1-11 and comparative example 1 unit dry matter straw is as follows: first measure the co...

Embodiment 1

[0043] A high-efficiency acidifying bacterial solution, the preparation method of which is as follows: take the biogas slurry from a chicken manure biogas project in Yanqing, separate the solid phase and liquid phase with a vibrating sieve, concentrate the solid phase, adjust the pH to 5.5 with hydrochloric acid, and place it for 3 days , the solid phase must be treated; the composite additive (including 100 parts by weight of CaO, 5 parts by weight of cellulase), sorghum straw and the above-mentioned liquid phase are mixed according to the weight ratio of 1:12:120, and the straw saccharification solution is obtained after standing for 5 days; The above-mentioned treated solid phase was added to the straw saccharification liquid, and the initial pH value was adjusted to 7.5 to carry out the fermentation reaction, and the content of volatile fatty acids (VFAs) in the fermentation liquid was measured until the content of volatile fatty acids (VFAs) in the fermentation liquid did n...

Embodiment 2

[0045] A high-efficiency acidifying bacterial solution, the preparation method of which is as follows: take the biogas slurry from a straw biogas project in Yanqing, separate the solid phase and liquid phase with a vibrating sieve, concentrate the solid phase, adjust the pH to 4 with hydrochloric acid, and place it for 1 day. The solid phase was treated; the composite additive (containing 50 parts by weight of CaO and 1 part by weight of cellulase), corn stalks and the above-mentioned liquid phase were mixed according to the weight ratio of 1:10:100, and the stalk saccharification liquid was obtained after being placed for 2 days; The above-mentioned treated solid phase is added to the above-mentioned straw saccharification liquid, and the initial pH value is adjusted to 6.5 to carry out the fermentation reaction, and the content of volatile fatty acids (VFAs) in the fermentation liquid is measured until the value of the content of volatile fatty acids (VFAs) does not increase f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com