Preparation method of composite negative electrode material for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering practical application, prone to separation, poor bonding strength, etc., to improve cycle stability and excellent electrochemical performance. , the effect of enhancing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using nano-silicon as raw material, in the ethanol solution of water, choose cetyltrimethylammonium bromide (CTAB) as dispersant, triethanolamine as reagent A, control m (nano-silicon) : m (water) : m(CTAB) : m (Reagent A) : m (absolute ethanol) =2 : 2 : 0.2 : 5 : 25, the reaction temperature is 25 ℃, the reaction time is 24 h, after centrifugation, the m - Si powder.

[0025] Will m -Si and graphite oxide according to 1 : 4 ratio to disperse, add polyvinylpyrrolidone (the addition ratio is 1 times the theoretical amount) as the reducing agent, ultrasonically stir and disperse evenly, then transfer it to a hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 160 ℃, and the reaction time is After 20 h, the obtained product was filtered and placed in aqueous solution for ion exchange for 24 h, washed and freeze-dried for 48 h to obtain m -SiG composite anode material.

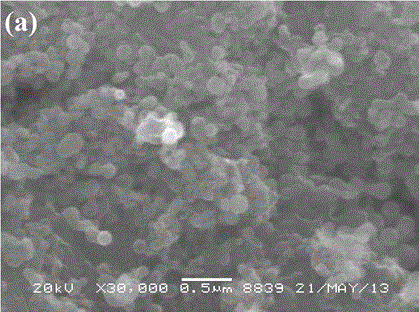

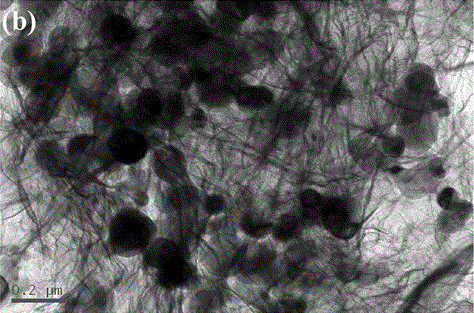

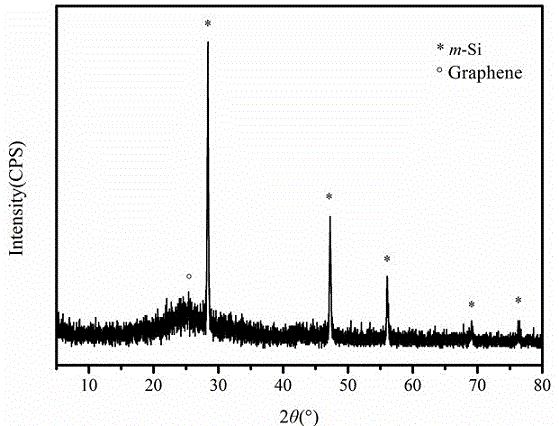

[0026] The SEM image of the obtained composite material is as...

Embodiment 2

[0031] Using nano-silicon as the raw material, in the ethanol solution of water, choose sodium dodecylbenzenesulfonate (SDBS) as the dispersant, the mixture of sulfuric acid and hydrogen peroxide as the reagent A, and control m (nano-silicon) : m (water) : m(SDBS) : m (Reagent A) : m(absolute ethanol) =1 : 2 : 0.5 : 8 : 25, the reaction temperature is 25 ℃, the reaction time is 24 h, after centrifugation, the m - Si powder.

[0032] Will m -Si and graphite oxide according to 1 : 2 ratio to disperse, add ethylene glycol (the addition ratio is 1.5 times of the theoretical amount) as the reducing agent, ultrasonically stir and disperse evenly, then transfer to the hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 180 ℃, and the reaction time is After 8 h, the obtained product was filtered and placed in aqueous solution for ion exchange for 48 h, washed and freeze-dried for 60 h, and its first-time delithiation specific capacity was as hi...

Embodiment 3

[0034] Using nano-silicon as raw material, in the ethanol solution of water, choose cetyltrimethylammonium bromide (CTAB) as dispersant, triethanolamine as reagent A, control m (nano-silicon) : m (water) : m(CTAB) : m(A) : m (absolute ethanol) =2 : 2 : 0.2 : 5 : 25, the reaction temperature is 25 ℃, the reaction time is 24 h, after centrifugation, the m - Si powder.

[0035] Will m -Si and graphite oxide according to 1 : 1 ratio for dispersion, adding polyethylene glycol (the addition ratio is 3 times the theoretical amount) as a reducing agent, ultrasonically stirred and dispersed evenly, then transferred to a hydrothermal reaction kettle for hydrothermal reaction, the reaction temperature is 250 ℃, and the reaction time After 4 hours, the obtained product was filtered and placed in aqueous solution for ion exchange for 72 hours, washed and freeze-dried for 72 hours, and its first-time delithiation specific capacity was as high as 1476.8 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com