A kind of decellularized anti-calcification heart patch and preparation method thereof

A decellularized and cardiac technology, applied in the field of biomaterials of tissue engineering, can solve the problems of prone to calcification, affect safety, prolong material degradation time, etc., to achieve beneficial growth, reliable safety, and reduce the risk of calcification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

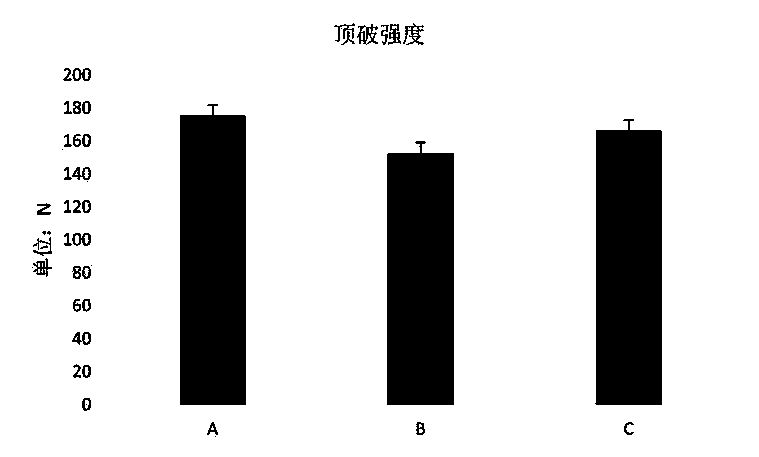

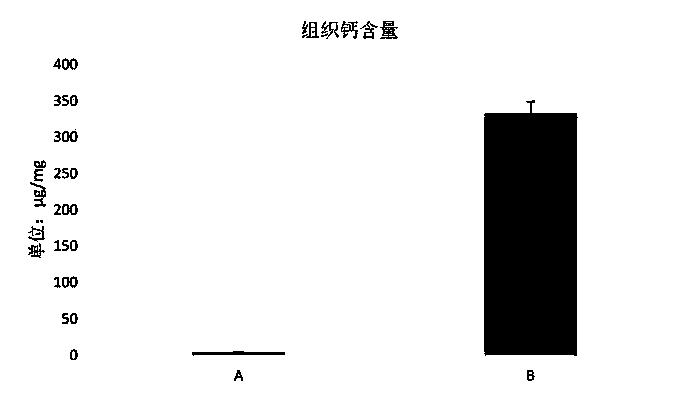

[0031] Example 1: Preparation of acellular and anti-calcified bovine pericardial heart patch

[0032] Step 1. Pretreatment of pericardial material: After removing blood stains and fatty tissue on the surface of fresh bovine pericardial material, add isopropanol at a mass ratio of 1:10, shake at 120 rpm for 12 hours, and rinse with purified water.

[0033] Step 2. Decellularization and anti-calcification treatment: Place the bovine pericardium obtained in Step 1 in a 3M sodium chloride mixed solution of 0.5% SDS and 0.75% sodium hydroxide, and shake treatment at 120 rpm for 10 minutes at 37°C, and then subject it to The purified water was oscillated at 120 rpm for 90 minutes, which was used as a cycle for a total of 3 cycles, and finally washed with purified water to neutrality.

[0034] Step 3. Terminal sterilization: use 15KGy of Co 60 Irradiate the bovine pericardium obtained in step two.

[0035] The bovine pericardium material has a denser structure. In this example, a higher conc...

Embodiment 2

[0036] Example 2: Preparation of acellular anti-calcification porcine pericardial heart patch

[0037] Step 1. Pretreatment of pericardial material: After removing blood stains and fatty tissue on the surface of fresh porcine pericardial material, add acetone at a mass ratio of 1:15, shake at 120rpm for 12 hours, and wash with purified water.

[0038] Step 2. Decellularization and anti-calcification treatment: Put the porcine pericardium obtained in step 1 in a 1.5M sodium chloride mixed solution of 0.3% SDS and 0.5% sodium hydroxide. At 37°C, shake at 100 rpm for 10 minutes, and then The purified water was oscillated at 100 rpm for 60 minutes, which was used as a cycle, and the total cycle treatment was 2 times, and finally the purified water was washed to neutrality.

[0039] Step three, terminal sterilization: use 100keV electron beam to process the porcine pericardium obtained in step two.

[0040] Porcine pericardium has a looser structure and higher fat content than bovine peric...

Embodiment 3

[0042] Step 1. Pretreatment of pericardial material: After removing blood stains and fatty tissue on the surface of fresh bovine pericardial material, add acetone at a mass ratio of 1:5, shake at 120rpm for 16 hours, and wash with purified water.

[0043] Step 2. Decellularization and anti-calcification treatment: Place the bovine pericardium obtained in step 1 in a 2.5M sodium chloride mixed solution of 0.2% SDS and 0.4% potassium hydroxide, and shake for 20 minutes at 130 rpm at 37°C, and then The purified water was oscillated at 130 rpm for 90 minutes, which was used as a cycle, and a total of 2 cycles were performed, and finally the purified water was washed to neutrality.

[0044] Step three, terminal sterilization: use ethylene oxide to sterilize the bovine pericardium material obtained in step two for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com