Preparation method of flexible nanometer interface composite textile material

A composite material and nanotechnology, applied in chemical instruments and methods, metal material coating technology, ion implantation plating, etc. The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a flexible nano-interface textile composite material, comprising the following steps:

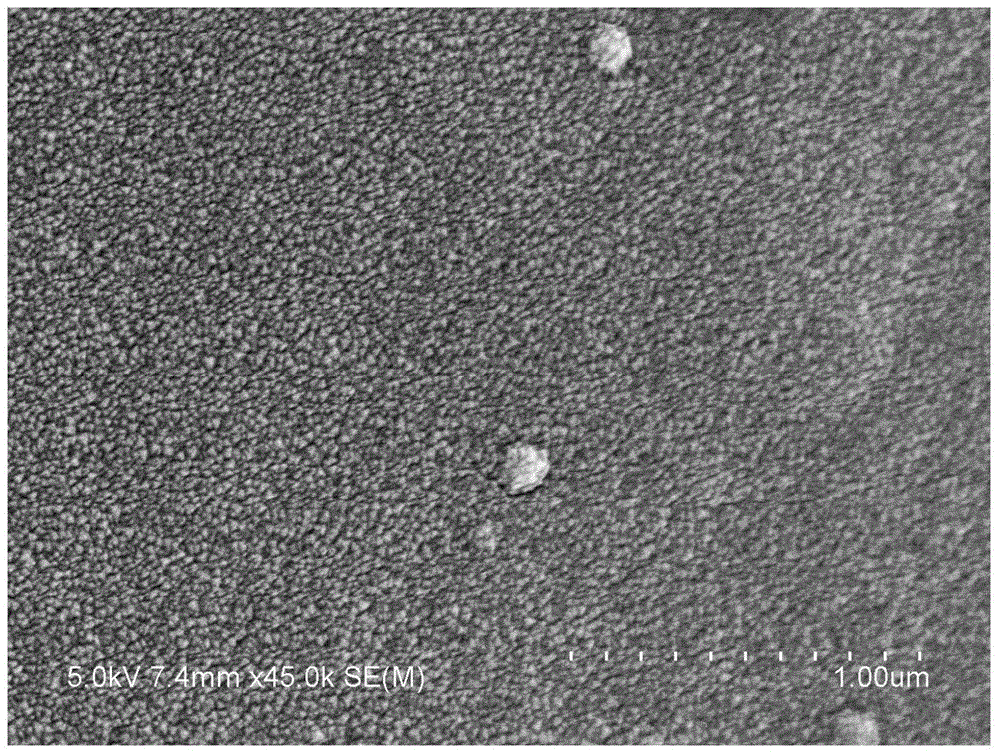

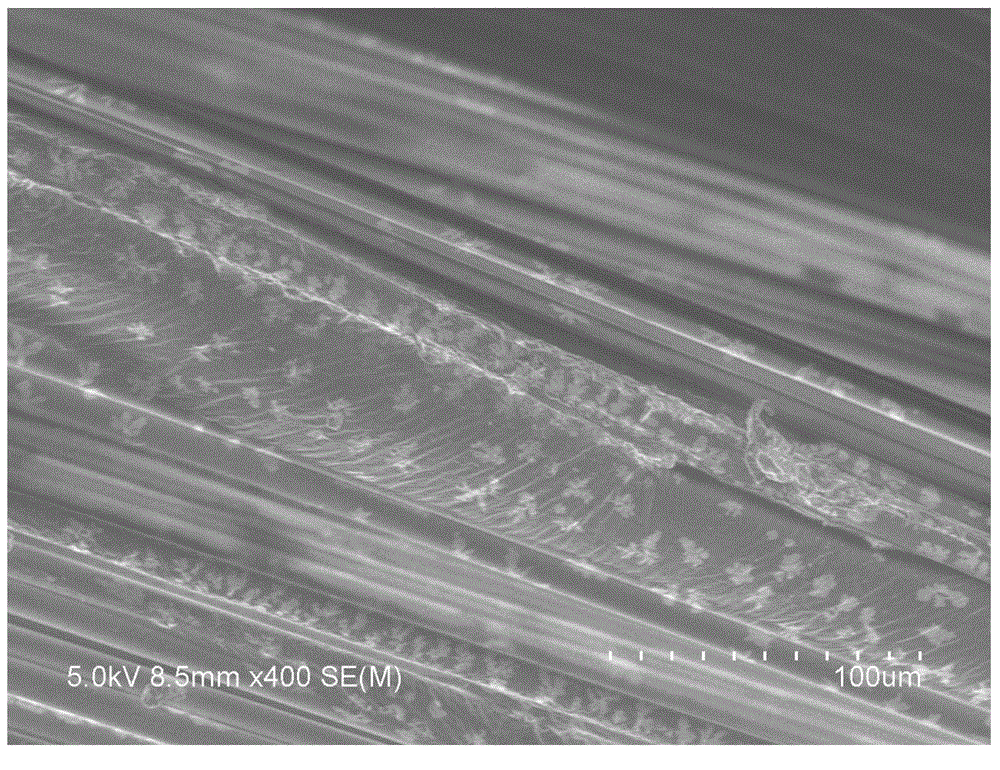

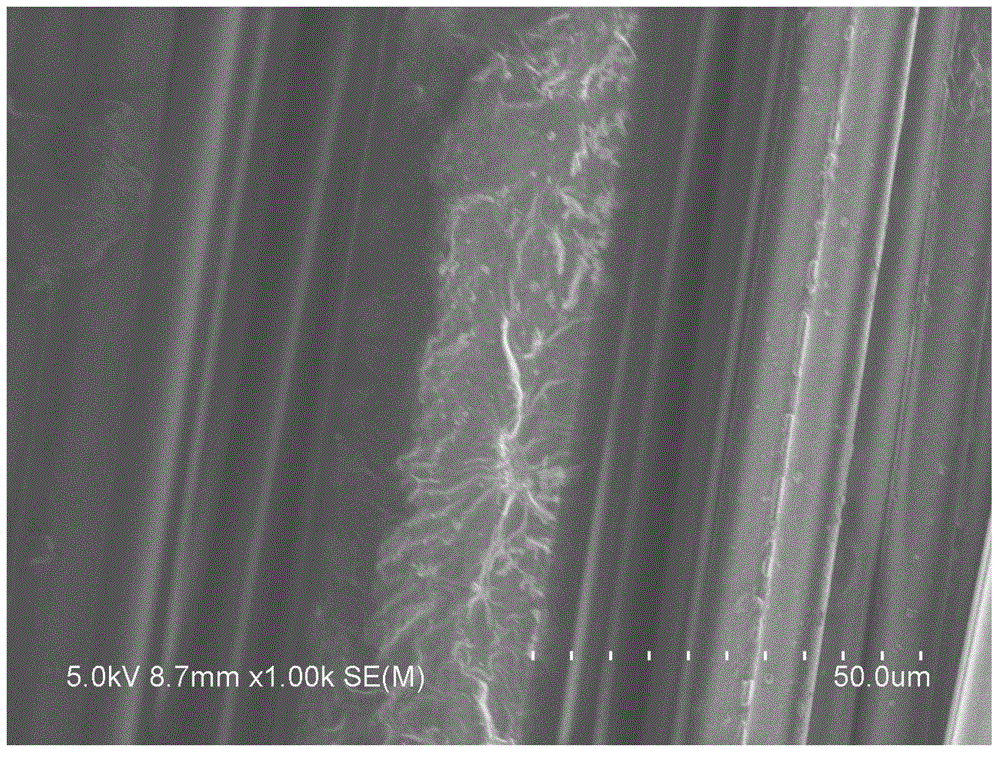

[0028] (1) The basalt non-weft cloth is cleaned and dried as the substrate, put into the magnetron sputtering device chamber, the reaction chamber is evacuated, and filled with high-purity argon as the reaction gas;

[0029] (2), use 99.99% metallic copper as the sputtering target material; Regulate pressure 0.5Pa, power 40W, gas flow rate 20sccm, sputter copper film on basalt non-weft cloth substrate, sputter 5min, obtain the single layer copper film Basalt non-woven fabric.

[0030] (3), immerse the basalt non-weft cloth with metal copper flexible film processed in step (2) in the boron phenolic resin solution according to the mass ratio of fabric and resin 4:6, and then place it in a ventilated place to dry for more than 1 day , to obtain prepreg cloth; cut the dried prepreg cloth into 20㎜×180㎜ size, put it in an oven at 110~120℃ for 30 minutes, then take i...

Embodiment 2

[0032] A method for preparing a flexible nano-interface textile composite material, comprising the following steps:

[0033] (1) The basalt non-weft cloth is cleaned and dried as the substrate, put into the magnetron sputtering device chamber, the reaction chamber is evacuated, and filled with high-purity argon as the reaction gas;

[0034] (2), use 99.99% metal oxide silicon dioxide as the target material; adjust the pressure 5Pa, power 50W, gas flow 40sccm, sputter the silicon dioxide film on the basalt non-weft cloth substrate, sputter 60min, obtain a single layer Basalt Laid Fabric with Silica Film.

[0035] (3), the basalt non-weft cloth with silicon dioxide flexible film treated by step (2) is immersed in the boron phenolic resin solution according to the mass ratio of fabric and resin 4:6, and then placed in a ventilated place to dry for 1 day As above, a prepreg was obtained. Cut the dried prepreg fabric into 20㎜×180㎜ size, put it in an oven at 110~120℃ for pre-bakin...

Embodiment 3

[0037] A method for preparing a flexible nano-interface textile composite material, comprising the following steps:

[0038] (1) The basalt non-weft cloth is cleaned and dried as the substrate, put into the magnetron sputtering device chamber, the reaction chamber is evacuated, and filled with high-purity argon as the reaction gas;

[0039] (2), use 99.99% metal copper as the sputtering target material; Regulate pressure 1Pa, power 70W, gas flow 40sccm, sputter copper film on the basalt non-weft cloth substrate, sputter 30min, obtain the basalt with single-layer copper film No weft.

[0040] (3), immerse the basalt non-weft cloth with metal copper flexible film processed in step (2) in the boron phenolic resin solution according to the mass ratio of fabric and resin 4:6, and then place it in a ventilated place to dry for more than 1 day , to obtain prepreg cloth; cut the dried prepreg cloth into 20㎜×180㎜ size, put it in an oven at 110~120℃ for 30 minutes, then take it out, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com