Preparation method of a novel three-dimensional nitrogen-doped graphene composite material system

A nitrogen-doped graphene and composite material technology, applied in the field of material science, can solve problems such as high cost, heavy pollution, and difficulty in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of a novel three-dimensional nitrogen-doped graphene composite system, which includes: dispersing graphene oxide in a solvent, adding nitrogen-containing compounds and selected materials, and reacting after uniform mixing, the reaction temperature is 0-150 ℃, the reaction time is 0-8 h, and then washed and dried in sequence to obtain a three-dimensional nitrogen-doped graphene composite system.

[0021] Further, the mass ratio of the graphene oxide to the nitrogen-containing compound is 0.1-1:100.

[0022] Further, the solvent may be selected from, but not limited to, any one or a mixture of two or more of water, methanol, ethanol, ethylene glycol, and N,N-dimethylformamide. Preferably from polar solvents, especially preferably from water.

[0023] Further, the nitrogen-containing compound may be selected from but not limited to ammonia water, urea, pyridine, pyrrole, hydrazine, dimethylamine, methylethylamine, ethylenediammo...

Embodiment 1

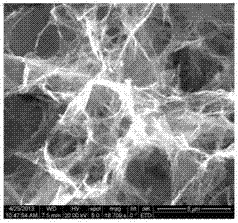

[0040] Take 5 mL of 4 mg / mL graphene oxide aqueous dispersion, 6 g of urea and 12.5 mL of deionized water and mix together, ultrasonically mix for 1 h, pour it into a polytetrafluoroethylene liner and put it into an autoclave, 150 The hydrothermal reaction was carried out at ℃ for 8 h, and it was naturally lowered to room temperature. After taking out the sample and immersing it in deionized water for 24 hours, the nitrogen-doped graphene product was obtained. The product can be further freeze-dried. For its structure, please refer to Figure 1a-Figure 1b , nitrogen doping amount is 10 wt.%.

Embodiment 2

[0042] Take 5 mL of 4 mg / mL graphene oxide aqueous dispersion, 6 g of urea, 12.5 mL of deionized water and 1 g of TiO2 The powders were mixed together, after being thoroughly mixed by ultrasonication for 1 h, poured into a polytetrafluoroethylene liner and placed in an autoclave, hydrothermally reacted at 150 °C for 8 h, and cooled down to room temperature naturally, and the samples were taken out and soaked in deionized water for dialysis for 24 hours After that, the three-dimensional nitrogen-doped graphene-TiO 2 Composite material, number NGT-2, its structure please refer to Figure 2a-Figure 2b , nitrogen doping amount is 10 wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com