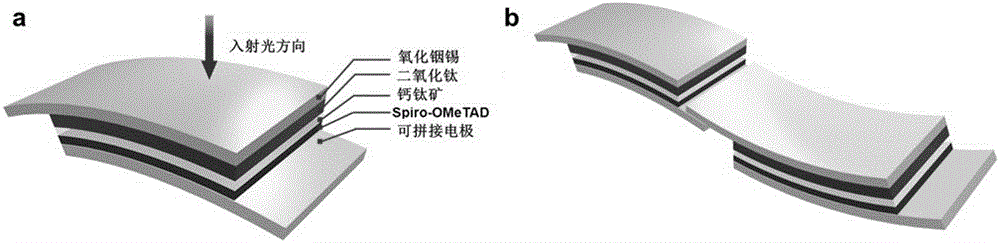

Perovskite solar cell capable of being spliced and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency of flexible devices, and achieve the effects of good flexibility, structural stability, and simple series connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

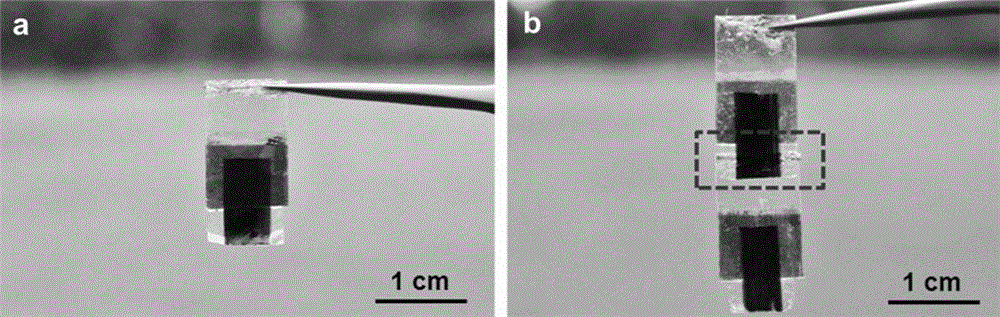

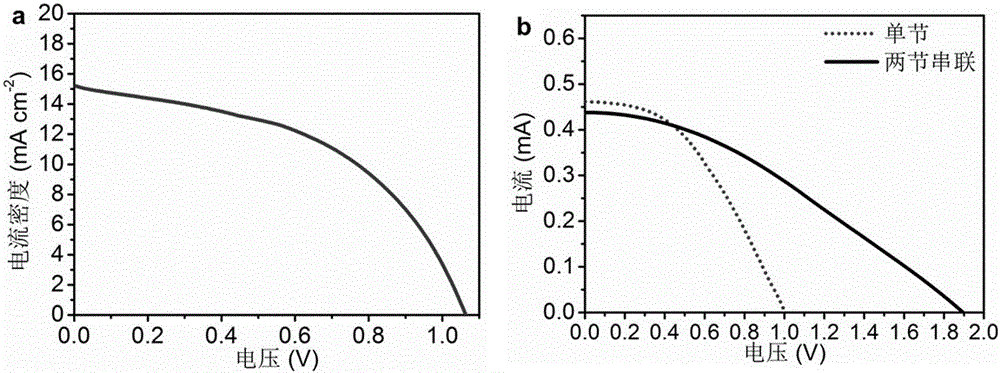

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of oriented carbon nanotube array: Synthesize a spinnable multi-walled carbon nanotube array by chemical vapor deposition. Catalyst uses Fe (2 nm) / Al 2 O 3 (10 nm), the carbon source is ethylene, the gas phase carrier is a mixed gas of argon and hydrogen, and chemical vapor deposition produces a spinnable carbon nanotube array.

[0027] (2) Preparation of self-healing polymer film: 20 g polydiacid and 7 g diethylenetriamine under argon atmosphere o C heat and stir for 24 hours. The product was dissolved in 100 mL chloroform, washed with 100 mL deionized water and 50 mL methanol respectively, and the solvent was removed by rotary evaporation to obtain a self-repairing polymer.

[0028] Take 1 g of self-healing polymer and dissolve it in 10 mL of chloroform to obtain a homogeneous solution. Add this solution dropwise to a clean glass slide. Volatilize the solvent at room temperature for 2 hours. o C dry for 20 minutes and evaporate the solvent to obtain a self...

Embodiment 2

[0034] (1) Preparation of oriented carbon nanotube array: Synthesize a spinnable multi-walled carbon nanotube array by chemical vapor deposition. Catalyst uses Fe (1.5 nm) / Al 2 O 3 (11 nm), the carbon source is ethylene, the gas phase carrier is a mixed gas of argon and hydrogen, and chemical vapor deposition produces a spinnable carbon nanotube array.

[0035] (2) Preparation of self-healing polymer film: 10 g polydiacid and 4 g diethylenetriamine under argon atmosphere 150 o C heat and stir for 30 hours. The product was dissolved in 50 mL chloroform, washed with 50 mL deionized water and 25 mL methanol, and the solvent was removed by rotary evaporation to obtain a self-repairing polymer.

[0036] Take 0.5 g of self-repairing polymer and dissolve it in 5 mL of chloroform to obtain a homogeneous solution. Add this solution dropwise to a clean glass slide, and evaporate the solvent for 2.5 hours at room temperature. o C dry for 30 minutes and evaporate the solvent to obtain a self-...

Embodiment 3

[0041] (1) Preparation of oriented carbon nanotube array: Synthesize a spinnable multi-walled carbon nanotube array by chemical vapor deposition. Catalyst uses Fe (1 nm) / Al 2 O 3 (10 nm), the carbon source is ethylene, the gas phase carrier is a mixed gas of argon and hydrogen, and chemical vapor deposition produces a spinnable carbon nanotube array.

[0042] (2) Preparation of self-healing polymer film: 5 g polydiacid and 3 g diethylenetriamine under argon atmosphere 140 o C heat and stir for 34 hours. The product was dissolved in 30 mL chloroform, washed with 30 mL deionized water and 15 mL methanol, and the solvent was removed by rotary evaporation to obtain a self-repairing polymer.

[0043] Dissolve 0.2 g of self-healing polymer in 3 mL of chloroform to obtain a homogeneous solution. Add this solution dropwise to a clean glass slide, and evaporate the solvent at room temperature for 3 hours. o C dry for 40 minutes and evaporate the solvent to obtain a self-healing polymer fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com