Nitrogen-doped carbon-coated silicon composite material and preparation method thereof

A composite material and silicon-coated technology, which is used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of electrical conductivity limiting the charge and discharge performance of composite materials, affecting the cycle performance of composite materials, and unfavorable large-scale preparation. Achieve good high-current charge-discharge characteristics, excellent electrochemical performance, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

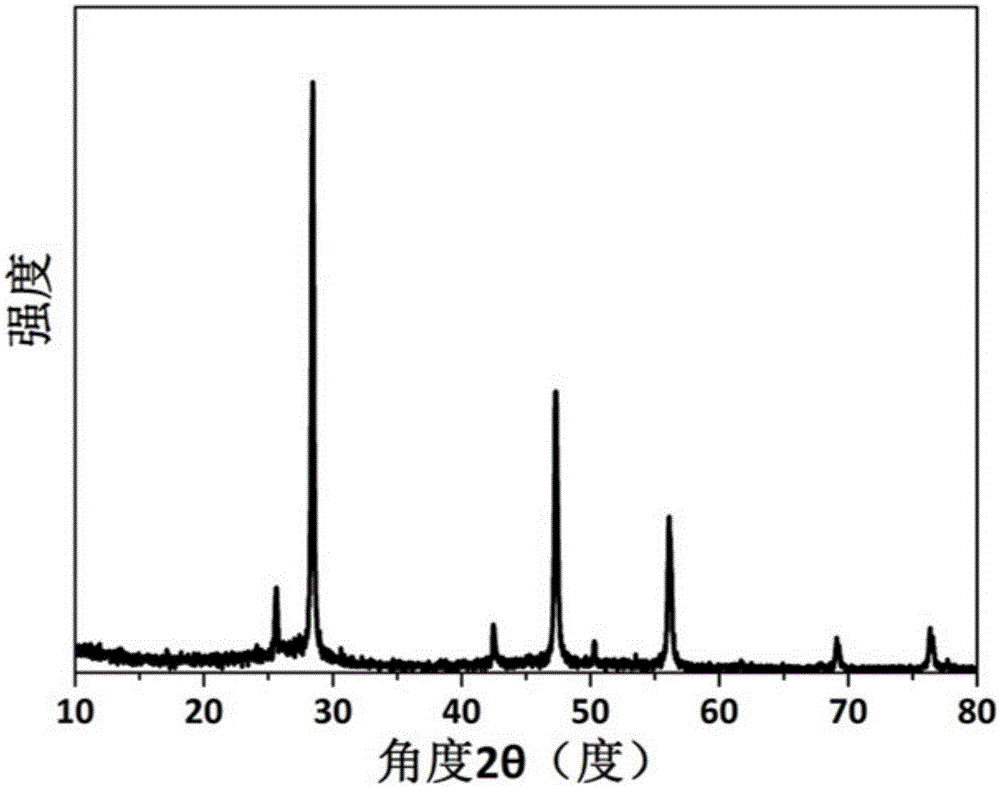

[0028] The preparation method of nitrogen-doped carbon-coated silicon composite material of the present invention comprises the following steps:

[0029] (1) Metal magnesium is mixed with silicon dioxide, and the silicon dioxide is converted into a silicon material with lithium storage activity by a metal magnesium thermal reduction method;

[0030] (2) adding the ionic liquid to the silicon material obtained in step (1), and mixing to obtain the precursor of the composite material;

[0031] (3) Heat-treating the composite material precursor obtained in step (2) under a protective atmosphere to obtain a nitrogen-doped carbon-coated silicon composite material.

[0032] In step (1), metallic magnesium refers to one or both of magnesium particles and magnesium powder.

[0033] In step (2), the ionic liquid refers to monoethyltrimethylimidazolium tricyanomethyl salt (EMIM-TCCN).

[0034] In step (2), the mass ratio of the silicon material to the ionic liquid is (2:9)-(4:1), and ...

Embodiment 1

[0039] Weigh 1g of silica pellet powder and 1g of magnesium powder, mix evenly, spread it on an alumina porcelain boat, place it in the heating zone of a tube furnace, and heat it at a rate of 2°C / min under the protection of an argon atmosphere. Raise the temperature to 680°C, keep it warm for 6 hours, and cool down to room temperature with the furnace, then place the magnesium heat product in 50mL of hydrochloric acid with a concentration of 1mol / L, stir for 5 hours, centrifuge, wash with distilled water three times, and place the obtained solid in In 50 mL of hydrochloric acid with a concentration of 1 mol / L, stir for 5 hours, centrifuge, wash with distilled water three times, wash with absolute ethanol twice, and finally vacuum-dry at 60°C for 24 hours to obtain nano silicon powder.

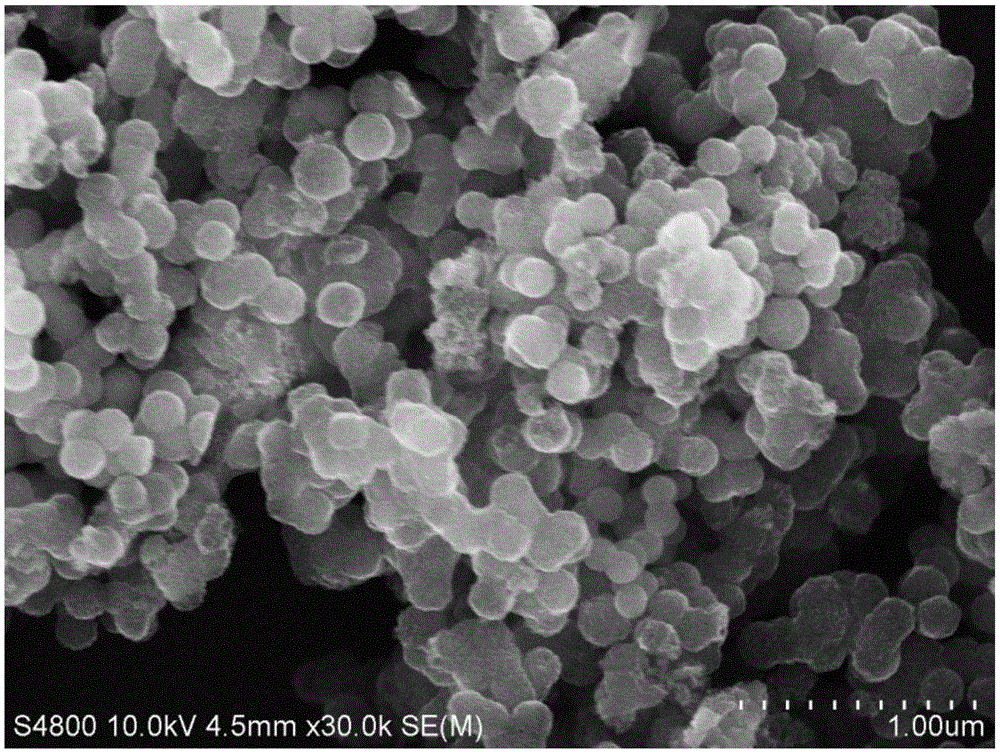

[0040] Mix 150mg of the above-mentioned nano-silicon powder with 150mg of the ionic liquid and grind them evenly to obtain the precursor of the composite material.

[0041] The precursor of th...

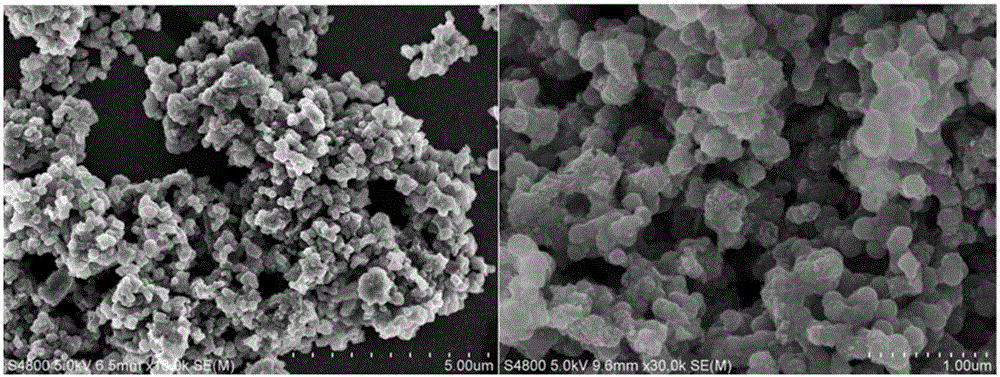

Embodiment 2

[0045] According to the method for preparing nano-silicon powder in Example 1, prepare nano-silicon powder.

[0046] Mix 100mg of the above-mentioned nano-silicon powder with 150mg of ionic liquid and grind them evenly to obtain the precursor of the composite material.

[0047] The precursor of the above-mentioned composite material was transferred to a tube furnace for heat treatment. Under an argon atmosphere, the temperature was raised to 200 °C at a rate of 2 °C / min, kept for 2 hours, and then the temperature was raised to 650 °C at a rate of 2 °C / min. ℃, keep it warm for 5 hours, and cool with the furnace to get the nitrogen-doped carbon-coated silicon composite material. The content of silicon in the composite material is 65.6%wt.

[0048] According to the method for preparing a button battery in Example 1, use the nitrogen-doped carbon-coated silicon composite material prepared in this example to make a button battery, and perform the charge-discharge cycle performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com