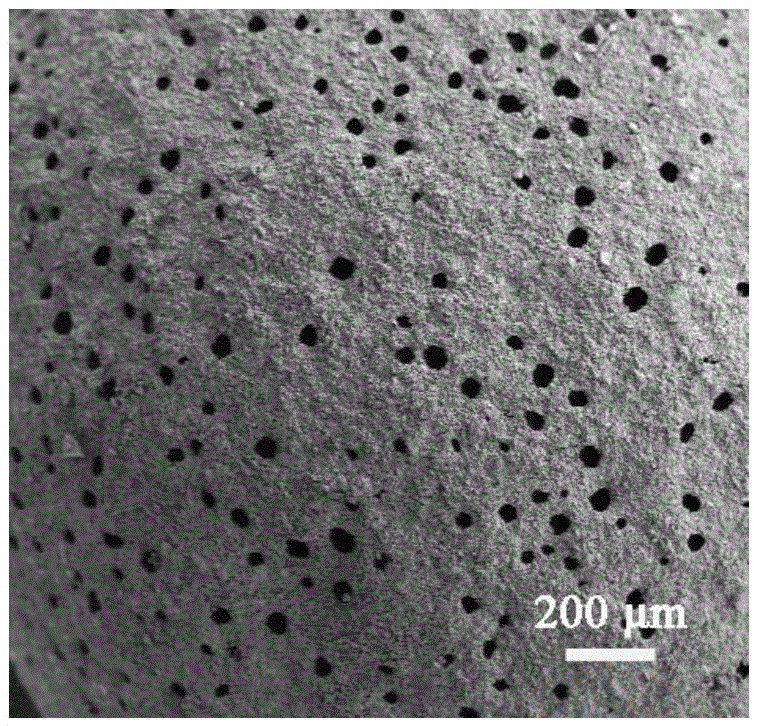

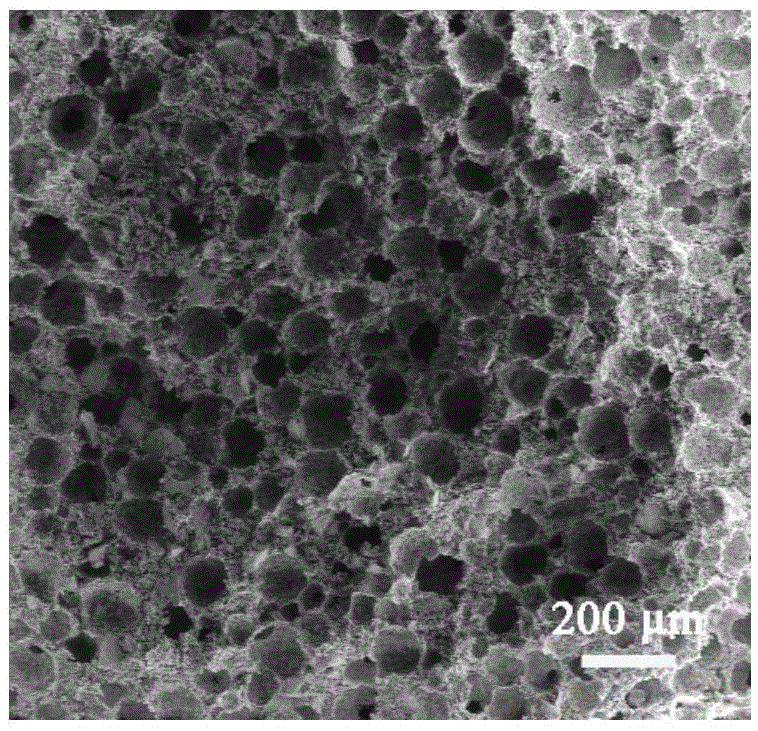

Porous calcium phosphate microsphere material with surface big holes and preparation method and application of porous calcium phosphate microsphere material

A technology of porous calcium phosphate and calcium phosphate bone, which is applied in the direction of non-active ingredient medical preparations, pharmaceutical formulations, medical science, etc. It can solve the problems of unfavorable growth of blood vessels and bone tissue, failure to match the growth rate of new bone, slow degradation rate, etc. problems, to achieve the effect of diversification of functions, realization of drug loading, and promotion of degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using gelatin as polysaccharide glue, modified starch as thickener, and "calcium dihydrogen phosphate-α-tricalcium phosphate-calcium carbonate" system bone cement to prepare porous calcium phosphate microspheres with large surface pores include:

[0034] (1) Dissolving gelatin at a ratio of 6g / 100mL in deionized water at 30°C to prepare a gelatin solution with a concentration of 6% (w / v);

[0035] (2) Dissolve the modified starch at a ratio of 2g / 100mL in deionized water at 25°C to prepare a modified starch solution with a concentration of 2% (w / v);

[0036] (3) Mix the gelatin solution obtained in step (1) with the modified starch solution obtained in step (2) to obtain a gelatin / modified starch mixed solution as "calcium dihydrogen phosphate-α-tricalcium phosphate-calcium carbonate" The liquid phase of the systemic bone cement;

[0037] (4) Mix the gelatin / modified starch mixed solution obtained in step (3) with the "calcium dihydrogen phosphate-α-tricalcium phosphat...

Embodiment 2

[0042] Using modified starch as polysaccharide glue, sodium alginate as thickener, and "tetracalcium phosphate-β-tricalcium phosphate-calcium dihydrogen phosphate" system bone cement to prepare porous calcium phosphate microspheres with large surface pores include:

[0043] (1) dissolving the modified starch at a ratio of 12g / 100mL in deionized water at 35°C to prepare a modified starch solution with a concentration of 12% (w / v);

[0044] (2) Sodium alginate was dissolved in 30°C deionized water at a ratio of 2g / 100mL to prepare a sodium alginate solution with a concentration of 2% (w / v);

[0045] (3) Mix the modified starch solution obtained in step (1) with the sodium alginate solution obtained in step (2) to obtain a modified starch / sodium alginate mixed solution as "tetracalcium phosphate-β-tricalcium phosphate-dicalcium phosphate The liquid phase of bone cement in hydrogen calcium” system;

[0046] (4) The modified starch / sodium alginate mixed solution obtained in step (...

Embodiment 3

[0051] The steps of preparing porous calcium phosphate microspheres with large surface pores by using xanthan gum as polysaccharide gum, hydroxypropyl cellulose sodium as thickener, and "partially crystalline calcium phosphate-calcium hydrogen phosphate" system bone cement include:

[0052] (1) dissolving xanthan gum in a ratio of 8g / 100mL in 40°C deionized water to make a xanthan gum solution with a concentration of 8% (w / v);

[0053] (2) Sodium hydroxypropyl cellulose was dissolved in 60°C deionized water at a ratio of 4g / 100mL to make a sodium hydroxypropyl cellulose solution with a concentration of 4% (w / v);

[0054] (3) The xanthan gum solution obtained in step (1) is mixed with the sodium hydroxypropyl cellulose solution obtained in step (2) to obtain a mixed solution of xanthan gum / sodium hydroxypropyl cellulose, which is used as "partial crystalline calcium phosphate" - the liquid phase of the bone cement of the "calcium hydrogen phosphate" system;

[0055] (4) Fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com