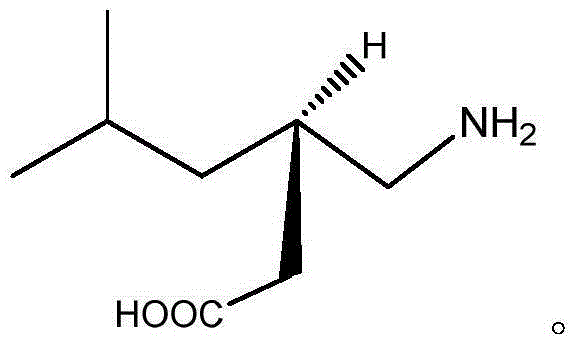

Preparation method for pregabalin

A pregabalin, reactive technology, applied in chemical instruments and methods, cyanide reaction preparation, preparation of organic compounds, etc., can solve the problems of difficult source of raw materials, low total yield of pregabalin, low product purity, etc. , to achieve the effect of ensuring total yield and purity, simple reaction route and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

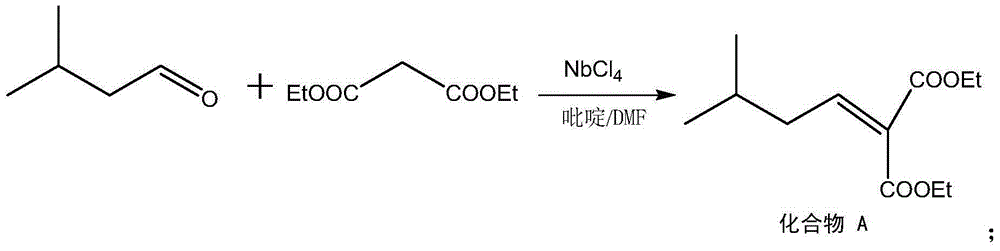

[0026] In the reaction vessel, put isovaleraldehyde, 0.8% niobium tetrachloride (the total mass of isovaleraldehyde and diethyl malonate is 100%), the DMF and pyridine mixed solvent of 2 volumes (in the form of cyclohexane The volume of the ketone is 1), and the mixture is cooled to -5°C. Then add 1.05% of diethyl malonate (based on the amount of isovaleraldehyde as 1), keep the temperature at 5°C, let it react for 12h under constant stirring, filter, distill, and wash with ether to obtain 2-carboxyethyl Base-5-methyl-2-hexenoic acid ethyl ester, this was named compound A.

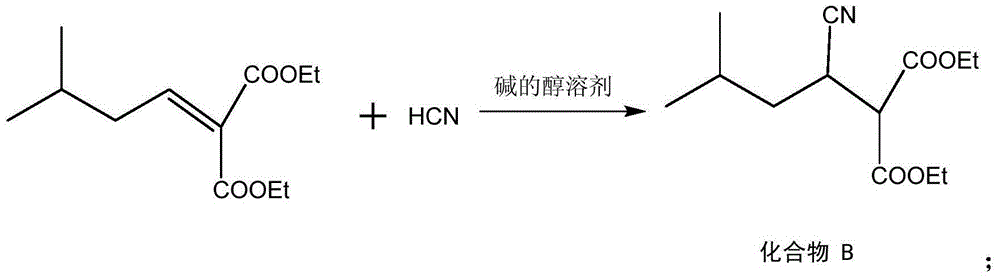

[0027] Put the above-mentioned compound A and ethanol with a mass of 3 (based on the mass of compound A as 1) in a high-pressure reactor, adjust the temperature to 20° C., and slowly drop in HCN with a mass of 1.02 (according to the mass of compound A) The mass is 1 meter). After reacting for 4 hours, the temperature was lowered to 10°C and the solid was filtered out. The solid was washed twice with wat...

Embodiment 2

[0032] In the reaction vessel, put isovaleraldehyde, 4% niobium tetrachloride (the total mass of isovaleraldehyde and diethyl malonate is 100%), DMF and pyridine mixed solvent of 10 volumes (in the amount of isovaler The volume of aldehyde is 1), and the mixture is cooled to 10°C. Then add 1.14 mass of diethyl malonate (based on the mass of isovaleraldehyde as 1), keep the temperature at 10°C, react for 6 hours under constant stirring, filter, distill, and wash with ether to obtain 1,1- Diethyl cyclohexyl allenoate, this was named compound A.

[0033]Put the above-mentioned compound A and methanol with a mass of 10 (based on the mass of compound A as 1) in a high-pressure reactor, adjust the temperature to 35 ° C, and slowly drop in HCN with a mass of 1.08 (calculated as the mass of compound A) The mass is 1 meter). After reacting for 2 hours, the temperature was lowered to 10°C and the solid was filtered out. The solid was washed twice with water, and recrystallized using ...

Embodiment 3

[0038] In the reaction vessel, put isovaleraldehyde, 2.4% niobium tetrachloride (the total mass of isovaleraldehyde and diethyl malonate is 100%), DMF and pyridine mixed solvent of 6 volumes (in the amount of isovaler The volume of aldehyde is 1), and the mixture is cooled to 7°C. Then add 1.095 mass of diethyl malonate (based on the mass of isovaleraldehyde as 1), keep the temperature at 7°C, react for 9 hours under constant stirring, filter, distill, and wash with ether to obtain 2-carboxyethyl Base-5-methyl-2-hexenoic acid ethyl ester, this was named compound A.

[0039] Put the above-mentioned compound A and ethanol with a mass of 6 (based on the mass of compound A as 1) in a high-pressure reactor, adjust the temperature to 28 ° C, and slowly drop in HCN with a mass of 1.06 (calculated as the mass of compound A) The mass is 1 meter). After reacting for 3 h, the temperature was lowered to 10° C. and the solid was filtered out. The solid was washed twice with water, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com