Acrylate emulsion and application thereof

A technology of acrylate and emulsion, which is applied in the field of polyester film, can solve the problems of environmental pollution, the difficulty of forming chemical bonds between the base coat and the functional coating, etc., and achieve the effect of improving the adhesion of the film and improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

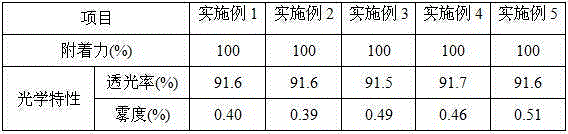

Examples

Embodiment 1

[0028] 1. Preparation of Acrylate Emulsion

[0029] (1) Add 220g of deionized water and 1g of sodium acrylamide stearate into the reactor, stir and mix quickly to obtain mixture A; weigh 1 / 3 of the weight of mixture A to dissolve 1g of potassium persulfate to obtain the initiator solution; take 3g acetoacetoxyethyl methacrylate, 25g methyl methacrylate, 23g ethyl acrylate, 1g methacrylic acid, 2g diacetone acrylamide, 5g isobornyl methacrylate and mix uniformly to obtain a mixed single Body B.

[0030] (2) Add 1 g of sodium bicarbonate and 1 / 8 of the weight of mixed monomer B to the reactor containing the remaining mixture A, and pre-emulsify for 20 minutes; the temperature of the reactor is raised to 80 ° C, and the initiator solution is added dropwise until the emulsion becomes After blueing, add the initiator solution and the remaining mixed monomer B dropwise at the same time, keep warm for 2.5 hours after the addition, cool down to 40°C, add N,N-dimethylethanolamine to ...

Embodiment 2

[0035] (1) Add 200g of deionized water and 0.5g of 3-allyloxy-2-hydroxy-1-propanesulfonic acid sodium salt into the reactor, stir and mix evenly to obtain mixture A; weigh 1 / 2 of the weight of mixture A 4 is used to dissolve 0.8g ammonium persulfate to obtain an initiator solution; weigh 2.5g acetoacetoxyethylene glycol methacrylate, 15g methyl methacrylate, 5g styrene, 15g isooctyl acrylate, 2g acrylic acid, Mix 2g of diacetone acrylamide and 6g of 2-phenoxyethyl acrylate to obtain mixed monomer B.

[0036] (2) Add 0.8g of ammonium bicarbonate and 1 / 5 of the weight of mixed monomer B to the reactor containing the remaining mixture A, pre-emulsify for 25 minutes, raise the temperature to 82°C, and add the initiator solution dropwise until the emulsion turns blue , add the initiator solution and the remaining mixed monomer B dropwise at the same time, keep warm for 1 hour after the addition, cool down to 45°C, add hexamethylenediamine to neutralize to a pH value of 8, and obtai...

Embodiment 3

[0040] (1) Add 150 g of deionized water, 0.7 g of sodium acrylamide stearate, and 0.8 g of 3-allyloxy-2-hydroxy-1-propanesulfonic acid sodium salt into the reactor, stir and mix evenly to obtain mixture A 1 / 2 of the weight of mixture A is weighed for dissolving 0.5g potassium persulfate to obtain initiator solution; 4g3-benzoyl ethyl acrylate, 25g methyl methacrylate, 15g styrene, 25g acrylic acid Ethyl ester, 5 g of methacrylic acid, 5 g of tetrahydrofuryl methacrylate, and 5 g of isobornyl methacrylate were uniformly mixed to obtain mixed monomer B.

[0041] (2) Add 1.5g of sodium bicarbonate and 1 / 7 of the weight of mixed monomer B to the reactor containing the remaining mixture A, and pre-emulsify for 30 minutes; the temperature of the reactor is raised to 75°C, and the initiator solution is added dropwise to the emulsion After turning blue, add the initiator solution and the remaining mixed monomer B dropwise at the same time, keep warm for 2 hours after the addition, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com