Multifunctional high-efficiency integrated air pollution processing material

An air pollution, integrated technology, applied in the direction of chemical/physical process, physical/chemical process catalyst, biocide, etc., to achieve the effect of no three wastes emission, outstanding efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] High specific surface coconut shell granular activated carbon, iodine value is 1800~1900mg / g, specific surface area is 2000~2100m 2 / g, ash content <2wt%, particle size 30-40 mesh, after soaking in 80℃ deionized water (liquid-solid ratio 2:1) for 3h, centrifuge to obtain solid wet material, and dry under microwave for 1h.

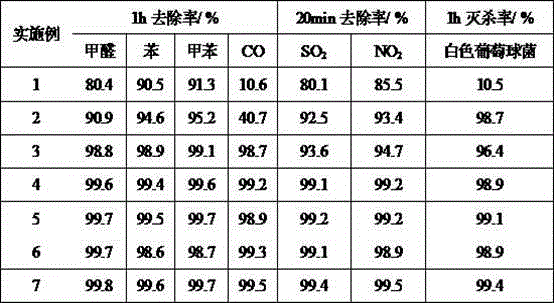

[0023] Take 500g of the treated granular activated carbon and fill it in the honeycomb panel. 3 National standard purification chamber test, temperature 18 ~ 22 ℃, humidity 50 ~ 80% RH, pollutant release concentration is 8 ~ 12 times the national standard allowable concentration, formaldehyde, benzene, toluene, CO removal efficiency and Staphylococcus albus killing efficiency The test period is 1h, SO 2 and NO 2 The removal efficiency test cycle is 20 minutes, and the purification effect is shown in Table 1.

Embodiment 2

[0025] Add 500g of titanium dioxide and 8g of chitosan to 5000ml of 10mol / L NaOH aqueous solution, conduct a hydrothermal reaction at 180°C for 12 hours, and cool to room temperature to obtain a dispersion of titanium oxide nanotubes; add 3g of alkyl polyglucoside to Ce 4+ The concentration is 0.2mol / L, Ag +Concentration is 0.005mol / L solution 5000mL, high-speed stirring for 20min to disperse, add 1mol / L sodium borohydride solution 50mL, 60 ℃ ~ 80 ℃ hydrothermal reaction for 4h, add all the titanium oxide nanotube dispersion liquid into high-speed stirring for 30min to obtain the active sol; 1800~1900mg / g, the specific surface area is 2000~2100m 2 / g, ash content <2wt%, particle size 30-40 mesh, high specific surface coconut shell activated carbon 500g was added to the active sol, stirred and impregnated at room temperature for 6h, after centrifugation, the wet material was dried under microwave for 1h to obtain Ti-Ce- Ag-alkyl polyglucoside modified carbon materials.

[002...

Embodiment 3

[0028] Add 500g of titanium dioxide and 6g of chitosan to 5000ml of 10mol / L NaOH aqueous solution, conduct a hydrothermal reaction at 180°C for 12 hours, and cool to room temperature to obtain a titanium oxide nanotube dispersion; 5g of quaternary ammonium salt cationic surfactant is added to Fe 3+ The concentration is 0.2mol / L, Pt 2+ The concentration is 0.002mol / L solution 5000mL, high-speed stirring for 20min to disperse, add 0.8mol / L sodium borohydride solution 50mL, 60℃~80℃ hydrothermal reaction for 5h, add all the titanium oxide nanotube dispersion liquid into high-speed stirring for 30min to obtain active sol ; 1800 ~ 1900mg / g, the specific surface area is 2000 ~ 2100m 2 / g, ash content <2wt%, particle size 30-40 mesh, high specific surface coconut shell activated carbon 500g was added to the active sol, stirred and impregnated at room temperature for 6h, after centrifugation, the wet material was dried under microwave for 1h to obtain Ti-Fe- Pt-quaternary ammonium sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com