Oilfield wastewater treatment process based on special membrane

A technology of oilfield wastewater and treatment process, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of direct evaporation investment and high operating costs, evaporation condensate COD not up to standard, Can not really meet environmental protection requirements and other issues, to achieve the effect of reducing drug consumption, ingenious design, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

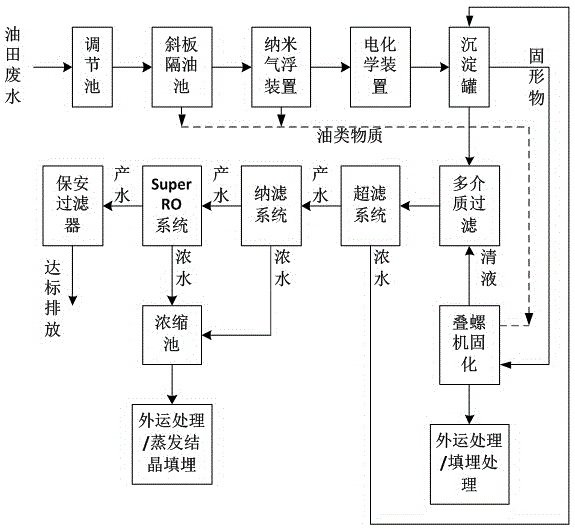

[0034] Such as figure 1 As shown, the oilfield wastewater treatment process based on special membranes includes the following steps:

[0035] (1) Introduce the gas field wastewater into the regulating pool for collection;

[0036](2) Carry out degreasing pretreatment of gas field wastewater in the inclined plate grease trap, and the removed oily substances enter the solidification process of the screw stacker;

[0037] (3) The effluent after pretreatment is subjected to air flotation treatment by the nano-air flotation device, and the removed oily substances and suspended solids also enter the solidification process of the screw stacker;

[0038] (4) The effluent after air flotation treatment is subjected to physical and chemical treatment by electrochemical device;

[0039] (5) The effluent after physical and chemical treatment is deposited and separated in the sedimentation tank, and filtered through a multi-media, and the precipitated solids also enter the solidification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com