Semi-conducting silicon rubber shielding material for cables

A shielding material, silicone rubber technology, applied in the field of semi-conductive silicone rubber shielding materials for cables, to achieve good electrical and mechanical properties, good radiation resistance, and excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

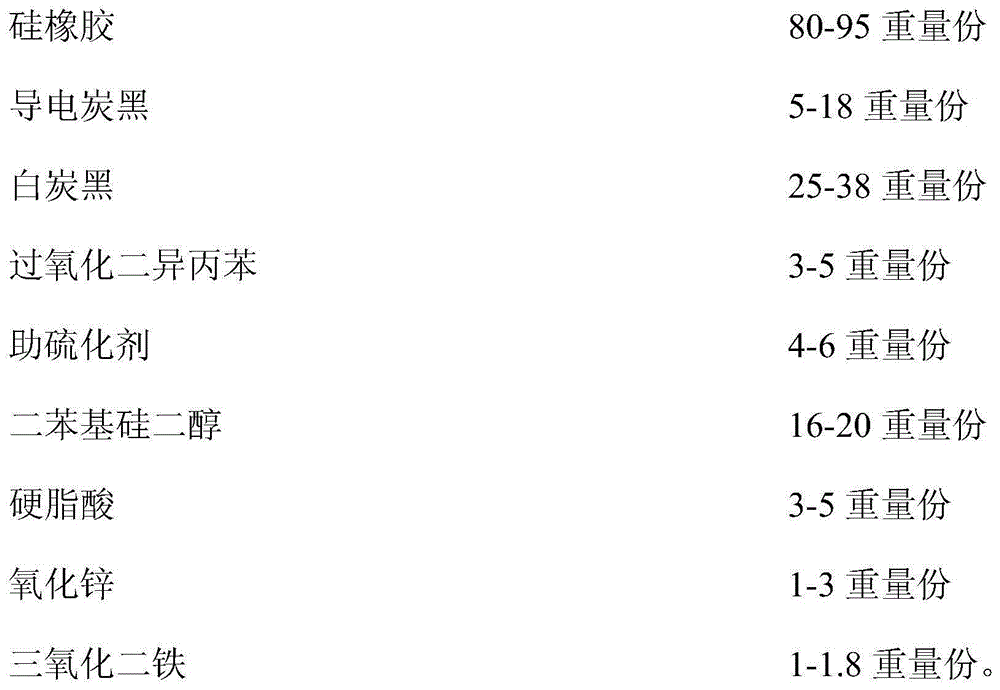

[0034] The semi-conductive silicone rubber shielding material for cables of the present embodiment is prepared from the following raw materials:

[0035]

[0036] The preparation method of the semi-conductive silicone rubber shielding material for the above-mentioned cables is as follows:

[0037] (1) Put the conductive carbon black into a 95°C oven and heat for 3h;

[0038] (2) Add silicone rubber, stearic acid, zinc oxide, ferric oxide, conductive carbon black, white carbon black, diphenyl Silicone glycol, triallyl cyanurate and dicumyl peroxide are mixed, the mixing temperature is 38°C, after the dicumyl peroxide is added, the glue can be removed after 4-5 times of thin pass piece;

[0039] (3) The mixed film is parked for 24 hours, and then re-milled at room temperature. The back-milled machine is used. After the rubber material becomes soft and the surface is smooth and flat, the film can be glued and released. The thickness of the obtained film is about 2 mm;

[004...

Embodiment 2

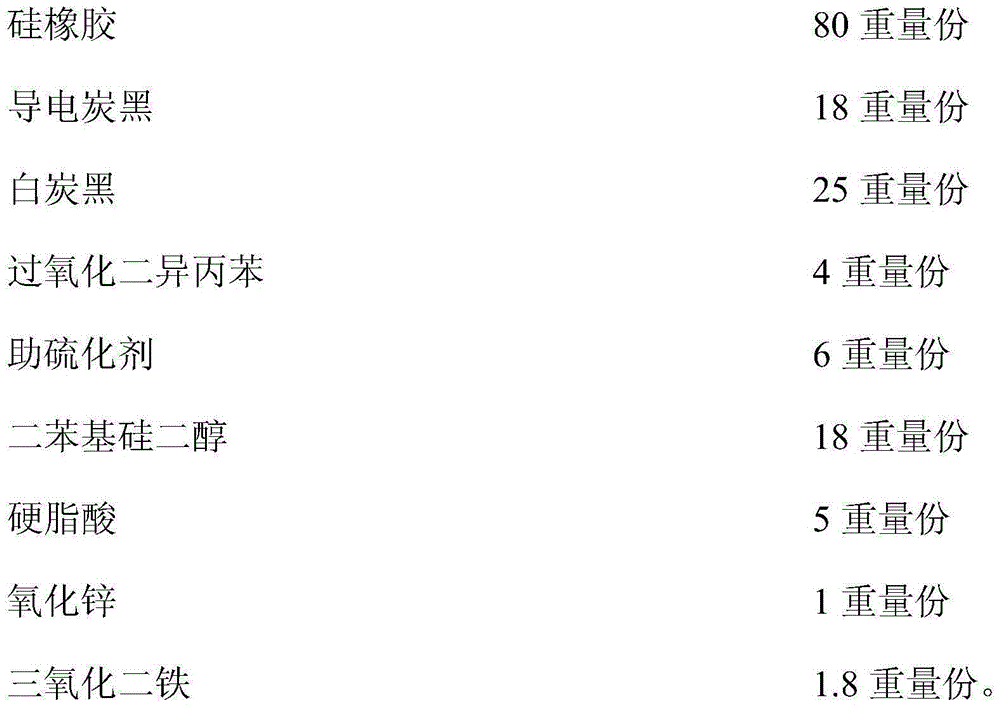

[0042] The semi-conductive silicone rubber shielding material for cables of the present embodiment is prepared from the following raw materials:

[0043]

[0044] The preparation method of the semi-conductive silicone rubber shielding material for the above-mentioned cables is as follows:

[0045] (1) Conductive carbon black is put into the oven of 100 ℃ and heated for 1h;

[0046] (2) Add silicone rubber, stearic acid, zinc oxide, ferric oxide, conductive carbon black, white carbon black, diphenyl Silicone glycol, triallyl cyanurate and dicumyl peroxide are mixed, the mixing temperature is 30°C, after the dicumyl peroxide is added, the glue can be removed after 4-5 times of thinning piece;

[0047] (3) The mixed film is parked for 30 hours, and then re-milled at room temperature. The back-milled machine is used. After the rubber material becomes soft and the surface is smooth and flat, the film can be glued and released. The thickness of the obtained film is about 1.5mm...

Embodiment 3

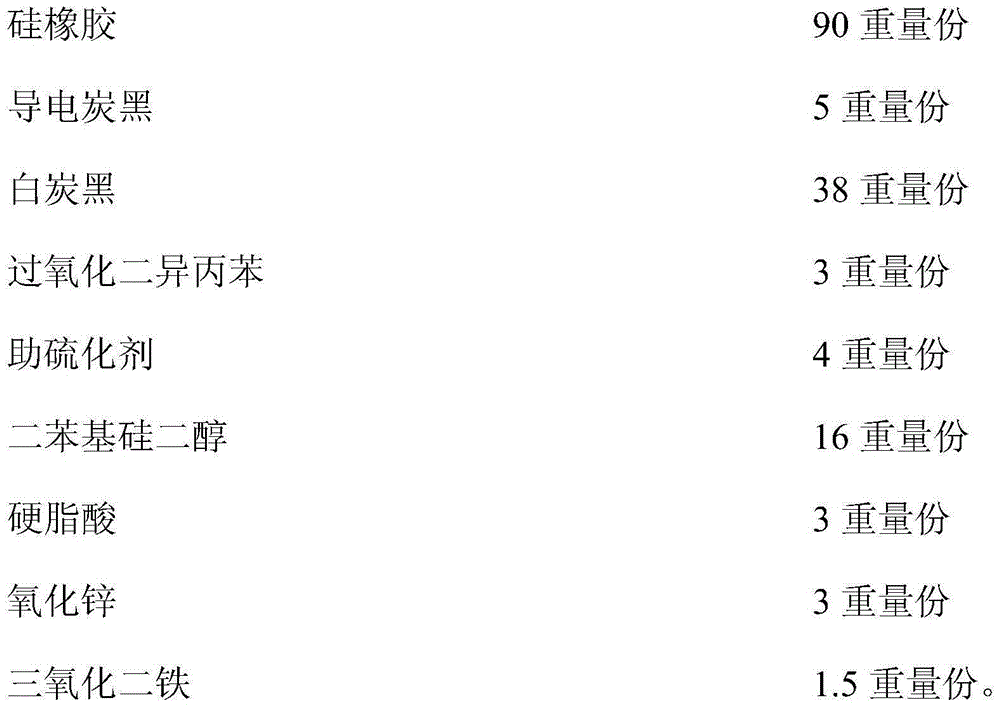

[0050] The semi-conductive silicone rubber shielding material for cables of the present embodiment is prepared from the following raw materials:

[0051]

[0052] The preparation method of the semi-conductive silicone rubber shielding material for the above-mentioned cables is as follows:

[0053] (1) Put conductive carbon black into an oven at 100°C and heat for 1.5h;

[0054] (2) Add silicone rubber, stearic acid, zinc oxide, ferric oxide, conductive carbon black, white carbon black, diphenyl Silicone glycol, triallyl cyanurate and dicumyl peroxide are mixed, the mixing temperature is 35°C, after the dicumyl peroxide is added, the glue can be removed after 4-5 times of thin pass piece;

[0055] (3) The mixed film is parked for 36 hours, and then re-milled at room temperature. The back-milled machine is used. After the rubber material becomes soft and the surface is smooth and flat, the film can be glued and released. The thickness of the obtained film is about 2 mm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com