Preparation method of low-VOC (volatile organic compound) composite coating applicable to field of heavy corrosion resistance

A composite coating, heavy-duty anti-corrosion technology, applied in the field of paint, can solve the problems of sagging, water-based paint can not dry, affecting production efficiency and production delivery, etc., to achieve the effect of excellent workability and excellent drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

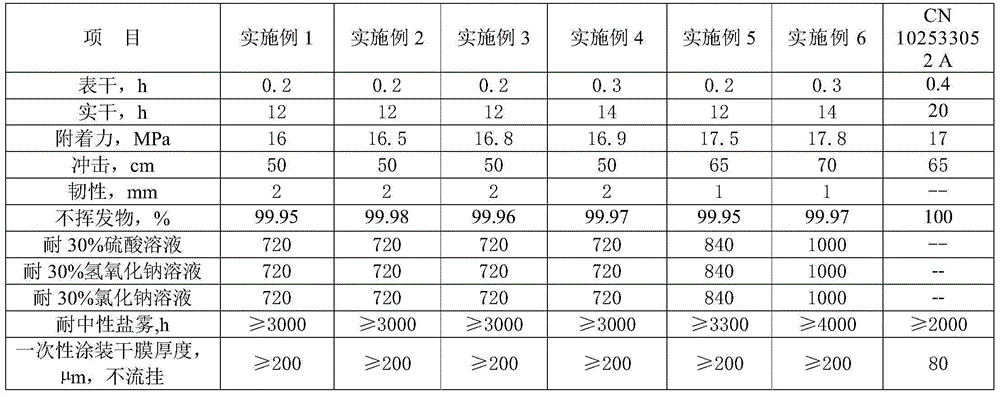

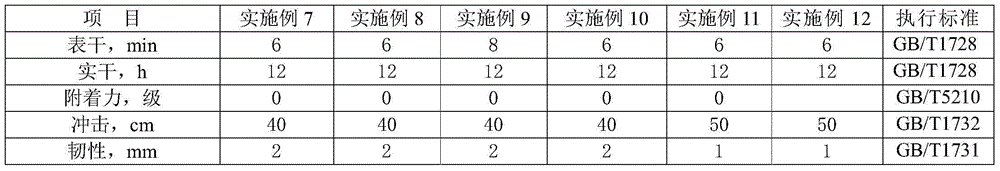

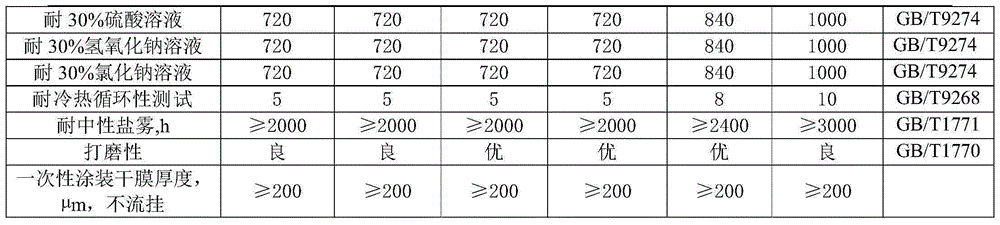

Examples

preparation example Construction

[0031] 1. Preparation method of low VOC solvent-free epoxy zinc-rich primer

[0032] The raw materials are as follows:

[0033] E51 epoxy resin (618 American Momentive)

[0034] Modified Resin (2602 Xylene Formaldehyde Resin Jiangsu Specialty Chemicals)

[0035] Epoxy reactive diluent (XY692 Anhui Xinyuan)

[0036] Zinc powder (600 mesh zinc powder Yangzhou Shuangsheng)

[0037] Environmentally friendly zinc phosphate (PZ20 Huanqi Chemical)

[0038] Dispersant (32500 Lubrizol)

[0039] Defoamer (625YCK)

[0040] Leveling agent (306BYK)

[0041] Salt spray resistance additive (1501 Hymings)

[0042] Fumed silica (N200 Huanqi Chemical)

[0043] Polyamide Wax Powder (LV Huanqi Chemical)

[0044] Hydrocarbon resin (DI Ruetger)

[0045] Phenalkamine curing agent (T-31 Jiangsu Sanmu)

[0046]Epoxy reactive diluent: including butyl glycidyl ether, alcohol glycidyl ether, butylphenyl glycidyl ether, cardanol glycidyl ether, trimethylolpropane polyglycidyl ether, 1,6-hexaned...

specific Embodiment approach

[0094] The raw materials are as follows:

[0095] Polyaspartic acid ester (F524 Fei Yang new material)

[0096] Rutile Titanium Dioxide (CR-501 Jinzhou Titanium Industry)

[0097] Carbon black (MA-100 Mitsubishi, Japan)

[0098] Nano barium sulfate (BS-80 Beijing Golden Horse)

[0099] Dispersant (9850 Hymings)

[0100] Defoamer (5500 Hymings)

[0101] Leveling agent (3777EFKA)

[0102] Fumed silica (N200 Huanqi Chemical)

[0103] Polyamide Wax (ULTRA Huanqi Chemical)

[0104] Polymethyl methacrylate (980N, Japan Asahi Kasei)

[0105] Isocyanate resin (3390 Bayer)

[0106] Mixed solvents (benzene, esters, ketones, hydrocarbon solvents Sinopec)

[0107] E component product formula: polyaspartate 55-65%, rutile titanium dioxide 20-25%, carbon black 0.5-1%, nano barium sulfate 5-10%, dispersant 0.3-0.5%, polyamide Wax powder 0.3-0.5%, fumed silica 0.2-0.3%, defoamer 0.1-0.2%, leveling agent 0.1-0.2%, polymethylpropyl methyl ester 3-5%, mixed solvent 4-8%

[0108] F com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com