Compound microbial agent for aerobic treatment on food processing wastewater and application of compound microbial agent

A technology for compounding microbial inoculants and food processing wastewater, applied in aerobic process treatment, microorganisms, microorganism-based methods, etc., can solve problems such as lack of stability, and achieve the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 fermented liquid

[0023] This embodiment only takes Lactobacillus casei (ACCC10640), Candida tropicalis (ATCC7394) and Bacillus licheniformis (CGMCC1.3448) as examples to describe the specific content of the invention in detail, and does not limit the present invention. Choice of three microbial sources.

[0024] (1) Activate the above Lactobacillus casei (ACCC10640), Candida tropicalis (ATCC7394) and Bacillus licheniformis (CGMCC1.3448) into their respective slant media for preservation, and culture them at 26-37°C for 16-72 hours.

[0025] Preservation of three kinds of microorganisms uses the slant culture medium formula as follows:

[0026] Lactobacillus casei medium: 10.0 grams of casein peptone, 10.0 grams of beef extract, 5.0 grams of yeast extract, 5.0 grams of glucose, 5.0 grams of sodium acetate, 2.0 grams of diammonium citrate, 1.0 grams of Tween80, K 2 HPO 4 2.0 g, M g SO 4 ·7H 2 O0.02 g, MnSO 4 ·H 2 O 0.05 g, CaCO 3 ...

Embodiment 2

[0034] 1, three kinds of microbial fermented liquids prepared in embodiment 1 are mixed uniformly by following weight parts and become composite microbial inoculum: 15 parts by weight of Lactobacillus casei fermented liquid, 5 parts by weight of Candida tropicalis fermented liquid, 7 parts by weight of Bacillus licheniformis fermented liquid parts by weight;

[0035] 2. Select the effluent from the anaerobic section of a food processing plant (fruit) sewage treatment plant (COD is 750mg / L, pH7.4), and add it to 4 contact oxidation reactors with an effective volume of 5L;

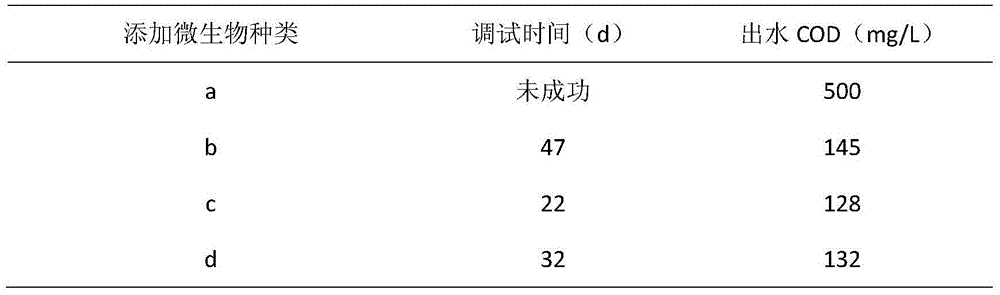

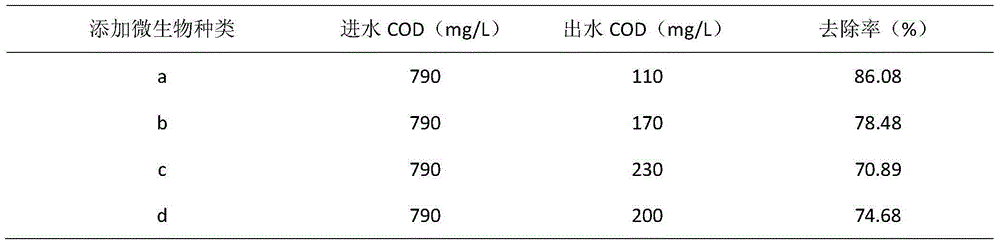

[0036]3. Add 3 mL of the following microbial fermentation liquid or microbial fermentation liquid mixture to the four contact oxidation reactors: a: Lactobacillus casei fermentation liquid, b: Lactobacillus casei fermentation liquid and Candida tropicalis fermentation liquid, c: Composite microbial agent prepared in step 1, d: blank control, add 100mL of aerobic sludge (solid content 5%). Mix evenly, keep t...

Embodiment 3

[0042] 1, three kinds of microorganisms in embodiment 1 are replaced with following source: Lactobacillus casei (CICC20363), Candida tropicalis (ATCC20326), Bacillus licheniformis (CICC10087); Prepare three kinds of microorganism fermentations according to the method for embodiment 1 Liquid, mixed uniformly according to the following parts by weight to become a composite microbial bacterial agent I: 10 parts by weight of Lactobacillus casei fermentation liquid, 8 parts by weight of Candida tropicalis fermentation liquid, 10 parts by weight of Bacillus licheniformis fermentation liquid; mix uniformly according to the following parts by weight To become a composite microbial bacterial agent II: 6 parts by weight of Lactobacillus casei fermentation liquid, 15 parts by weight of Candida tropicalis fermentation liquid, and 20 parts by weight of Bacillus licheniformis fermentation liquid.

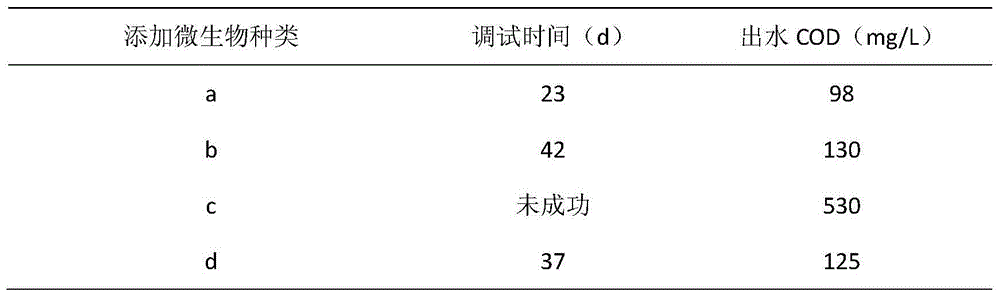

[0043] 2. Select the effluent from the anaerobic section of the sewage treatment plant of a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com