A kind of polymer antibacterial agent for water-based ecological synthetic leather and preparation method thereof

A polymer antibacterial agent and synthetic leather technology, applied in the field of chemical additives, can solve the problem of the failure of antibacterial agents, and achieve the effect of strong antibacterial activity, good compatibility and good migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

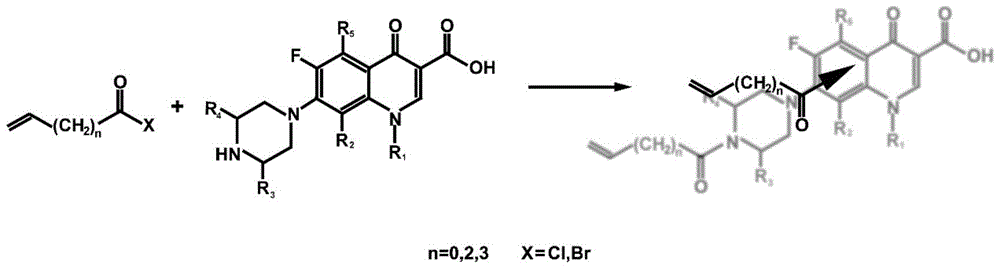

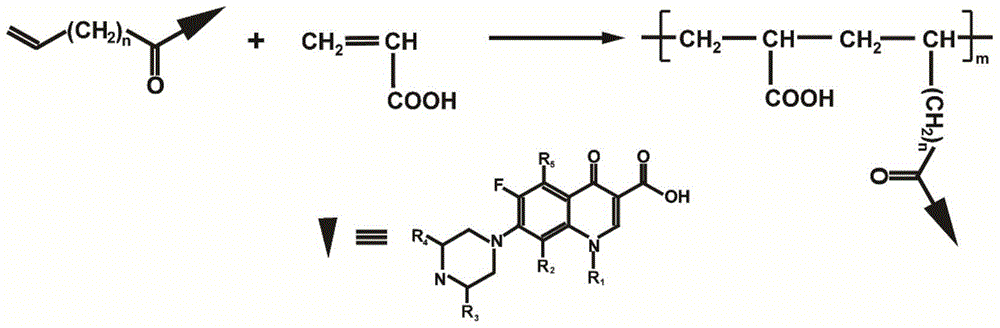

Image

Examples

Embodiment 1

[0026] (1) Mix 10 parts of ciprofloxacin, 4 parts of pyridine and 300 parts of dichloromethane, stir at 0°C for 30 minutes, then add 13 parts of acryloyl chloride dropwise under continuous stirring and protection of inert gas, after the dropwise addition The temperature was raised to 20° C. and reacted for 1 hour; after the reaction was completed, the above mixture was poured into n-hexane, and the precipitation was repeatedly washed with water and dried to obtain vinylated ciprofloxacin.

[0027] (2) 10 parts of vinylated ciprofloxacin, 200 parts of acrylic acid, 2 parts of azobisisobutyronitrile and 500 parts of tetrahydrofuran were mixed uniformly, under inert gas protection and continuous stirring, refluxed at 80 ° C for 20 hours, the reaction After completion, the above mixture is poured into cyclopentane, and the product is directly dissolved in deionized water after drying to obtain a water-soluble polymer antibacterial agent.

[0028] Mix 0.5 parts of the polymer antib...

Embodiment 2

[0031] (1) Mix 15 parts of norfloxacin, 6 parts of triethylamine and 400 parts of dichloromethane, stir at 2°C for 40 minutes, then add 6 parts of acryloyl chloride dropwise under continuous stirring and inert gas protection, add dropwise After completion, the temperature was raised to 25° C. to react for 1.5 hours; after completion of the reaction, the above mixture was poured into n-hexane, and the precipitation was repeatedly washed with water and dried to obtain vinyl norfloxacin.

[0032] (2) Mix 14 parts of vinyl norfloxacin, 260 parts of acrylic acid, 6 parts of azodicyclohexanitrile and 600 parts of N'N-dimethylformamide, under the protection of inert gas and continuous stirring, The mixture was refluxed at 70° C. for 24 hours. After the reaction was completed, the above mixture was poured into diethyl ether. After drying, the product was directly dissolved in deionized water to obtain a water-soluble polymer antibacterial agent.

Embodiment 3

[0036] (1) 20 parts of enoxacin, AlCl 3 8 parts and 450 parts of tetrahydrofuran were mixed evenly, stirred at 3°C for 50 minutes, then 8 parts of 4-pentenoyl chloride were added dropwise under continuous stirring and under the protection of inert gas, and the temperature was raised to 25°C for 2 hours after the completion of the reaction; , the above mixture was poured into n-hexane, and the precipitation was repeatedly washed and dried to obtain vinylated enoxacin;

[0037] (2) Mix 18 parts of vinylated enoxacin, 320 parts of acrylic acid, 8 parts of azobisisoheptanenitrile and 700 parts of ethanol, under the protection of inert gas and continuous stirring, reflux at 70 ° C for 26 hours to react After completion, the above mixture is poured into petroleum ether, and the product is directly dissolved in deionized water after drying to obtain a water-soluble polymer antibacterial agent.

[0038] Mix 0.5 parts of the polymer antibacterial agent prepared above, 100 parts of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com