A kind of positive electrode material of lithium ion secondary battery and preparation method thereof

A technology for secondary batteries and positive electrode materials, applied in the field of positive electrode materials for lithium ion secondary batteries and their preparation, can solve problems such as insufficient cycle performance, safe electrochemical performance, etc., and achieve excellent cycle performance and good protection of particle structure. , the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

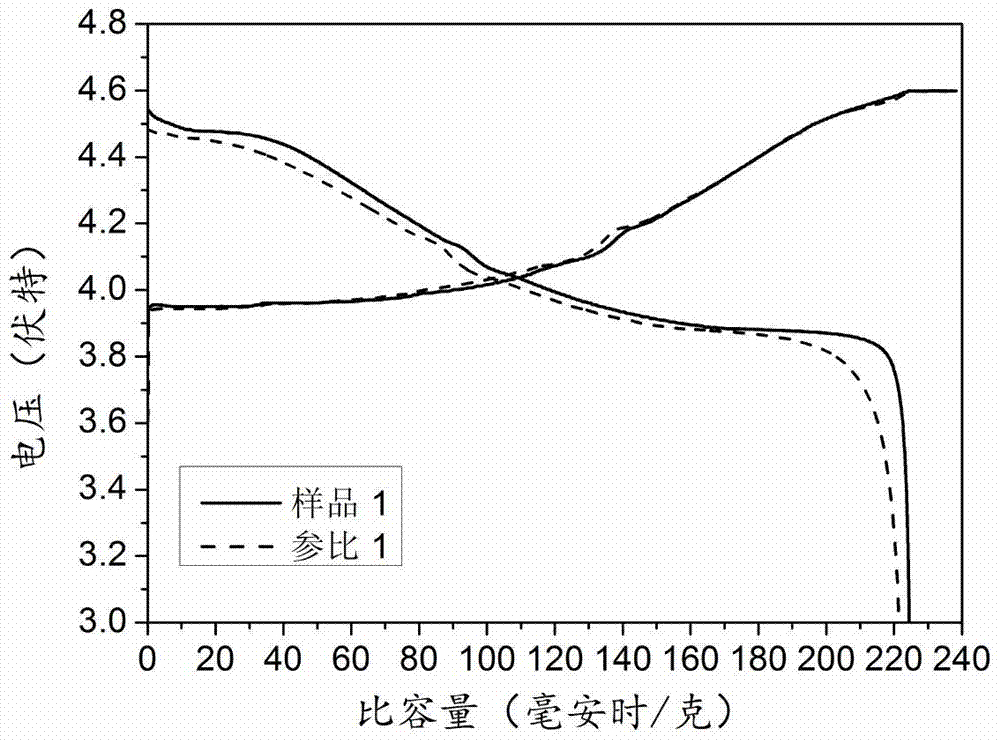

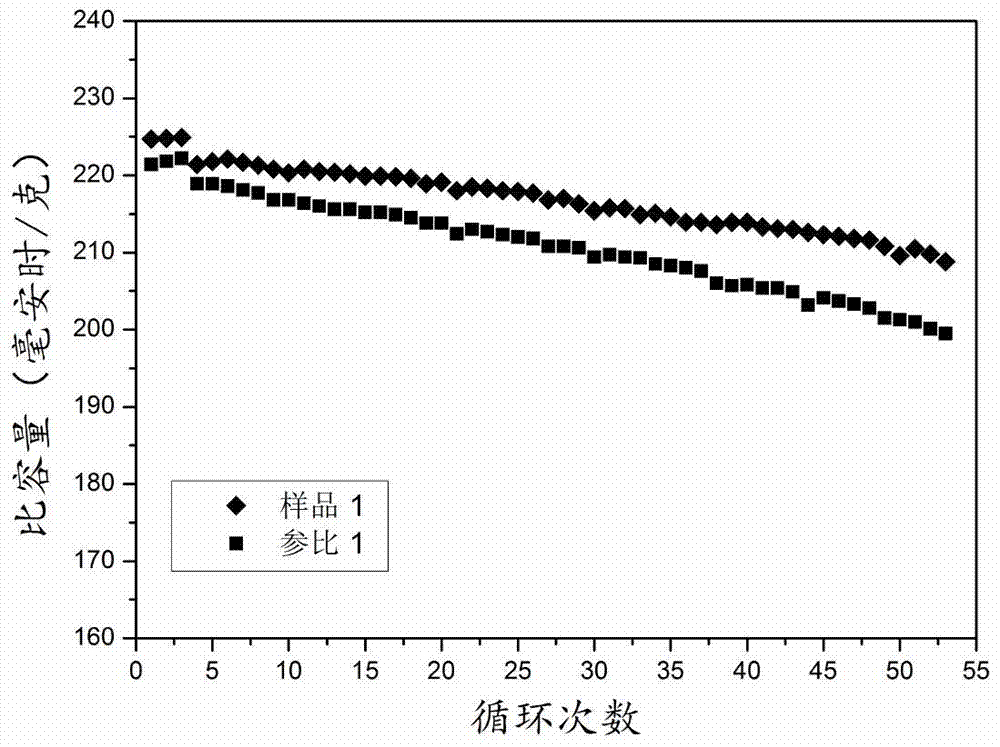

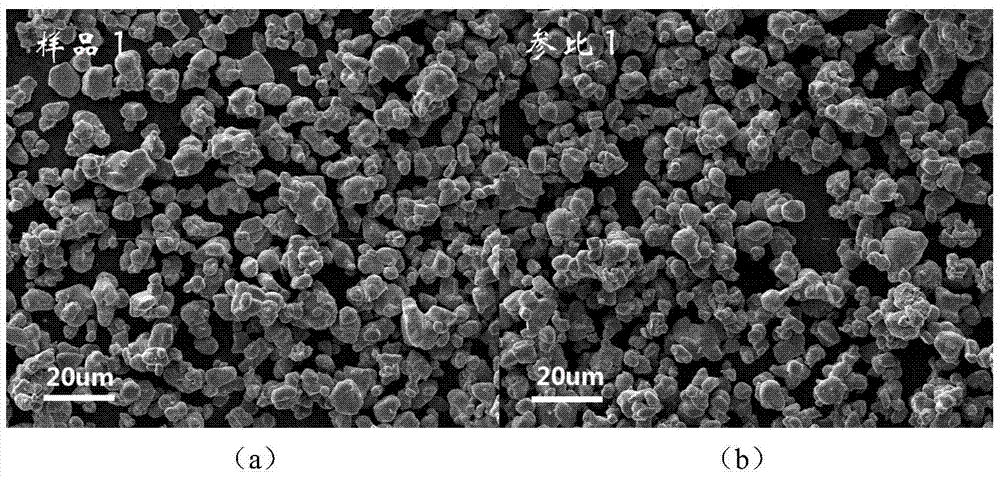

[0025] 1) Lithium, cobalt, magnesium, nickel, and manganese are carried out ball milling and mixing lithium carbonate, cobalt tetroxide, magnesium acetate, nickel acetate, and manganese acetate in a molar ratio of 1.20:0.98:0.005:0.005:0.01; The above materials are placed in a muffle furnace and calcined at 1000°C for 10 hours in an air atmosphere to obtain a single crystal lithium cobaltate doped with magnesium, nickel, and manganese in the bulk; the sintered materials are coarsely crushed and then crushed and sieved by a jet mill , and finally a primary doped lithium cobaltate material is obtained.

[0026] 2) According to the molar ratio of aluminum and cobalt of 0.015:1.00, aluminum isopropoxide and lithium cobaltate material doped once obtained in step 1) were wet mixed and evaporated to dryness with stirring. The evaporated material is placed in a muffle furnace and calcined at 750°C for 5 hours in an air atmosphere to obtain a single crystal lithium cobaltate doped with...

Embodiment 2

[0029] 1) Cobalt, magnesium, nickel, and manganese are prepared in a ratio of 0.97:0.005:0.005:0.02 by cobalt sulfate, magnesium sulfate, nickel sulfate, and manganese sulfate into hydroxide precipitates by co-precipitation method, and the It is placed in a muffle furnace at 550°C and sintered for 5 hours to make doped cobalt oxide. Lithium and cobalt are mixed with lithium carbonate and the prepared doped cobalt oxide in a molar ratio of 1.02:1 by ball milling. After the mixing is completed, the above materials are placed in a muffle furnace and calcined at 1000°C for 10 hours in an air atmosphere to obtain a single crystal lithium cobaltate doped with magnesium, nickel, and manganese in the bulk; the sintered materials are coarsely crushed and then air-flow Grind, crush and sieve to obtain a primary doped lithium cobalt oxide material.

[0030] 2) Place aluminum isopropoxide and lithium cobaltate material doped once in step 1) in ethanol solution according to the ratio of alu...

Embodiment 3-4

[0033] The method for preparing the positive electrode active material in Example 1 was followed, except that the aluminum isopropoxide was replaced by zirconium n-butoxide and magnesium acetate respectively. The prepared active material was tested for electrochemical performance. Use the prepared electrode sheet as the working electrode of the half-cell, metal lithium as the counter electrode, and use 1mol / L LiPF 6 / Ethylene carbonate (EC)-dimethyl carbonate (DMC) (mass ratio of EC and DMC 1:1) is used as electrolyte, is assembled into battery in glove box and carries out charge and discharge test to its battery, and the voltage range is 3.0-4.6V, charge and discharge current density is 0.2C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com