Integral type ruthenium catalyst used for purifying PTA oxidized tail gas as well as preparation method and application of integral type ruthenium catalyst

A ruthenium catalyst, tail gas oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve high halogenated by-products, poor toxicity resistance, and Halogen poisoning and other problems, to achieve the effect of high activity, low cost, stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

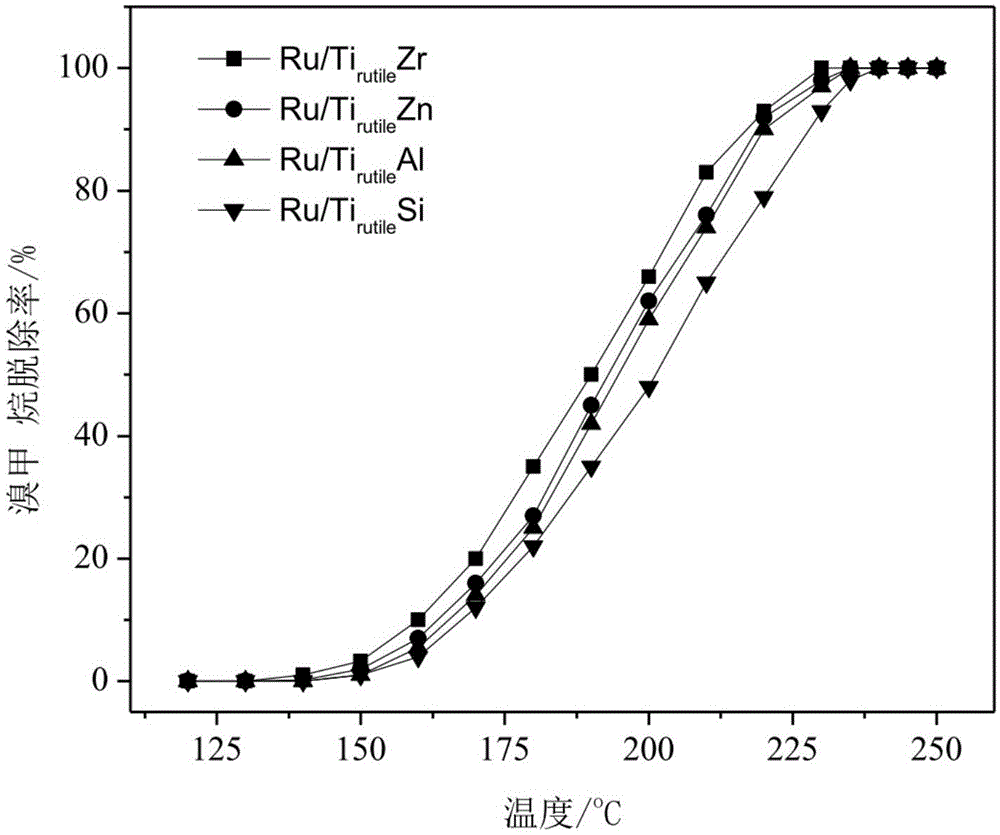

[0045] A catalyst for catalyzing and oxidizing PTA waste gas is mainly divided into two processes: powder catalyst preparation and integral catalyst preparation. Wherein, the powder catalyst includes an active component, a first carrier and a second carrier, the active component is ruthenium, and the first carrier is rutile phase TiO 2 , the second carrier is ZrO 2 , based on 100 wt% of the mass of the powder catalyst, the mass percentage of ruthenium in the active component of the powder catalyst is 1 wt%, and the mass ratio of the first carrier to the second carrier is 5:1. In the monolithic catalyst, the catalyst coating amount was 160 g / L.

[0046] Above-mentioned catalyst preparation comprises the steps:

[0047] (1) The rutile phase TiO 2 Add it into the aqueous solution of zirconium nitrate and stir it at the same time to obtain a mixed slurry, then let it stand for 1 hour, after the impregnation is sufficient, place it in an oven at 110°C to remove water for the fir...

Embodiment 2

[0052] Except that the mass percentage of the active component ruthenium element in the catalyst is 0.2wt.%, the rest is the same as that of Example 1.

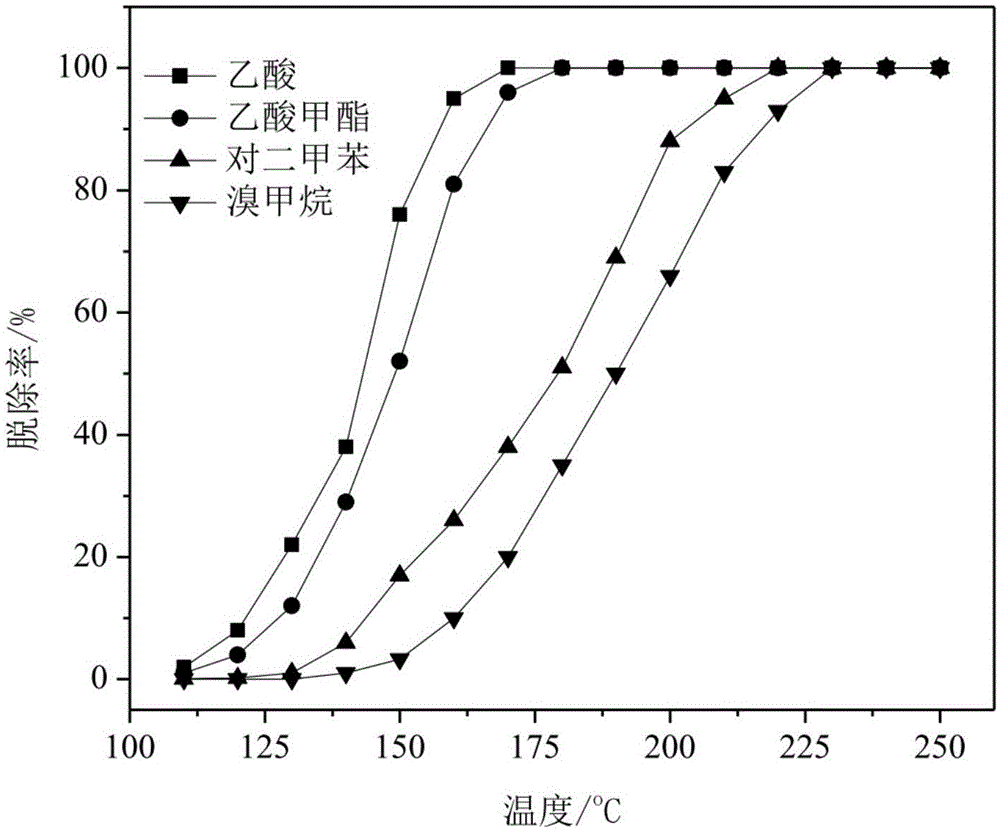

[0053] The complete oxidation temperatures of the catalyst p-bromomethane, acetic acid, methyl acetate, and p-xylene are 320°C, 235°C, 240°C, and 260°C, respectively. 2 Selectivity ≥ 99%.

Embodiment 3

[0055] Except that the mass percentage of the active component ruthenium element in the catalyst is 2wt.%, the rest is the same as that of Example 1.

[0056] The complete oxidation temperatures of the catalyst p-bromomethane, acetic acid, methyl acetate, and p-xylene are 235°C, 170°C, 190°C, and 220°C, respectively. 2 Selectivity ≥ 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com