Preparation method for flower-like Ag2CO3/Mg-Al-NO3 LDHs nanometer material

A technology of magnesium-aluminum hydrotalcite and silver carbonate is applied in chemical instruments and methods, water pollutants, light water/sewage treatment, etc., to achieve the effects of simple preparation process and process, easy operation of preparation process and process, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

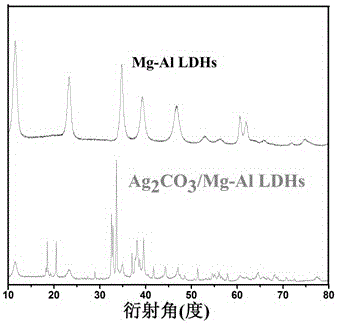

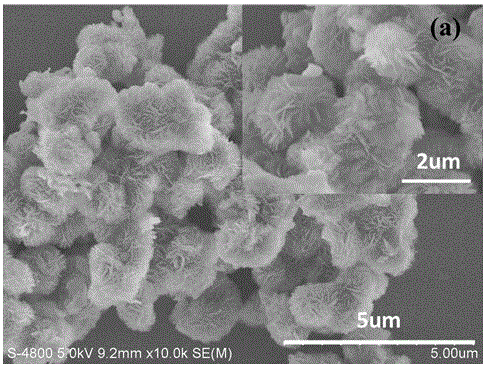

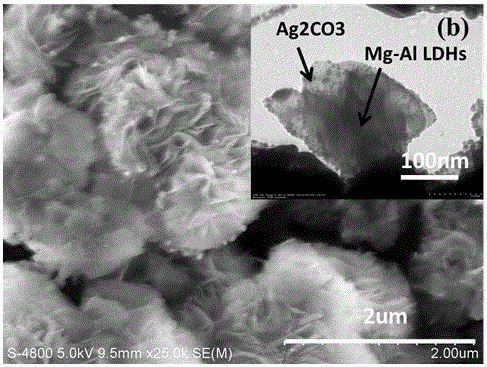

[0023] a flower-like Ag 2 CO 3 / Mg-Al-NO 3 The preparation method of LDHs nano-photocatalytic material is a preparation method of flower-shaped photocatalytic nano-materials that efficiently degrade dyes of different ion types and phenol solutions, including the following steps:

[0024] (1) At room temperature, add 8, 4, 60mmol of magnesium nitrate, aluminum nitrate and urea into 60mL of ethylene glycol and ultrapure water (V / V=9) mixed solution, fully dissolve and put it into the hydrothermal reaction kettle , reacted at 160°C for 6h, cooled (normal temperature), filtered and separated the product, washed it with deionized water and ethanol, and finally dried at 100°C for 12h to obtain flower-shaped Mg-AlLDHs;

[0025] (2) Add 1.2 g of flower-like Mg-AlLDHs into 300 mL of 0.5 M sodium carbonate solution and stir for 24 hours to obtain Mg-Al-NO 3 / CO 3 LDHs sample, and then the sample was centrifuged, washed twice with water, and finally dried at 60°C for use;

[0026] (...

Embodiment 1

[0031] At room temperature, weigh 2.0513g, 1.5001g, and 3.036g of magnesium nitrate, aluminum nitrate, and urea, respectively, and add them to 60mL of a mixed solution of ethylene glycol and ultrapure water (V / V=9), fully dissolve at room temperature, and load In a hydrothermal reaction kettle, react at 160°C for 6h. After cooling, the product is separated by filtration, cleaned with deionized water and ethanol, and finally dried at 100°C for 12h to obtain flower-like Mg-AlLDHs.

Embodiment 2

[0033] First, weigh 1.2g of the Mg-AlLDHs prepared in Embodiment 1 and add it into 300mL of 0.5M sodium carbonate solution, stir for 24h, and then add the Mg-Al-NO 3 / CO 3 LDHs samples were separated by centrifugation, washed twice with water, and finally dried at 60°C for later use. Then, after weighing 0.3g of the Mg-Al-NO obtained above 3 / CO 3Add the LDHs sample to 10mL of 0.5M sodium carbonate solution, stir for 15min, put the beaker into an oil bath and heat it to 60°C (keep stirring slowly) until it is completely evaporated to dryness, to obtain Mg-Al-CO 3 LDHs samples were finally dried at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com