Preparation method for diphenyl ether serial sulfonyl azide compounds

A technology of diphenyl ethers and sulfonyl azide, which is applied in the field of preparation of diphenyl ether sulfonyl azide compounds, can solve the problems of high treatment cost, large amount of acetic acid, and large waste water discharge, and is easy to recycle and apply , fast response, complete conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Put the diphenyl ether-4,4′-bissulfonylhydrazide raw materials into a 250-mL three-necked flask, add the selected solvent and acid, stir and dissolve to form a solution. Slowly add an aqueous solution of sodium nitrite of appropriate concentration dropwise, and continue to react for 60 minutes after the dropwise addition until TLC shows that there is no raw material. Filtrate in vacuo, wash with normal water, and dry under reduced pressure to constant weight to obtain a white solid. If the product purity needs to be further improved, it can be purified by silica gel column chromatography. TLC analysis purity, product structure by 400MHz 1 HNMR (DMSO- d 6 ) analytical verification. The reaction process is as follows:

[0021] .

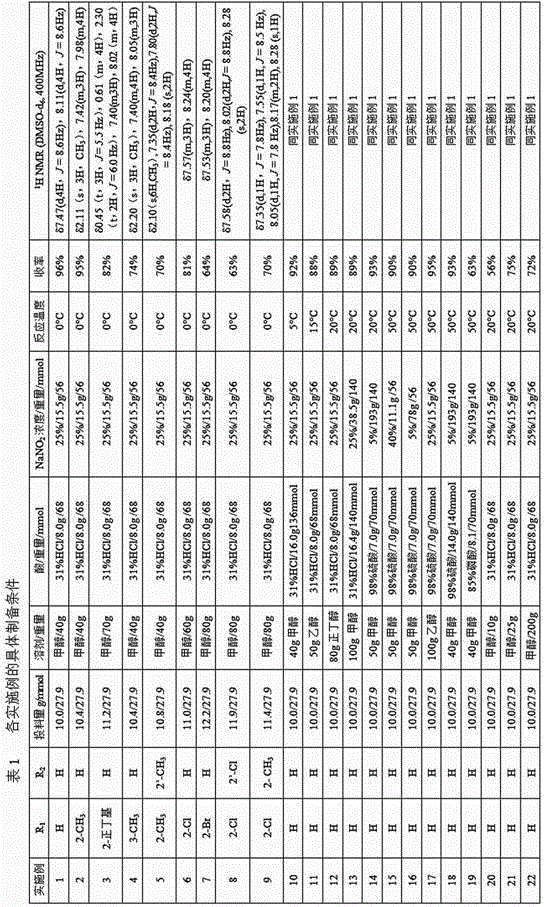

[0022] The specific conditions such as the starting material and the amount of feed intake, reaction solvent, acid and sodium nitrite of each preparation example operated by the above-mentioned method, the temperature of reaction and yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com