Uvioresistant sheath-core composite self-adaptive fiber for Z-pinch wire-array load and preparing method thereof

An anti-ultraviolet, self-adaptive technology, applied in fiber processing, rayon manufacturing, fiber chemical characteristics, etc., can solve the problem that self-adaptive technology cannot complete the assembly process, and achieve straightness, high rebound rate, and high loading accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

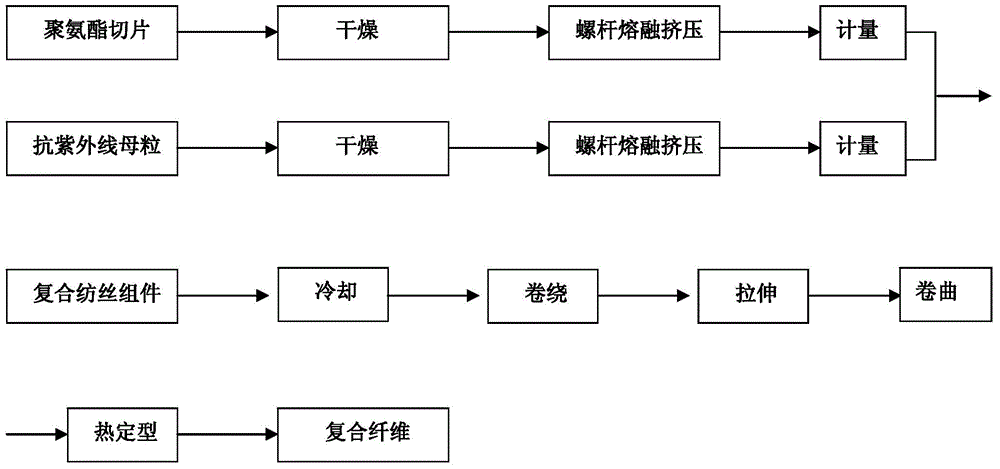

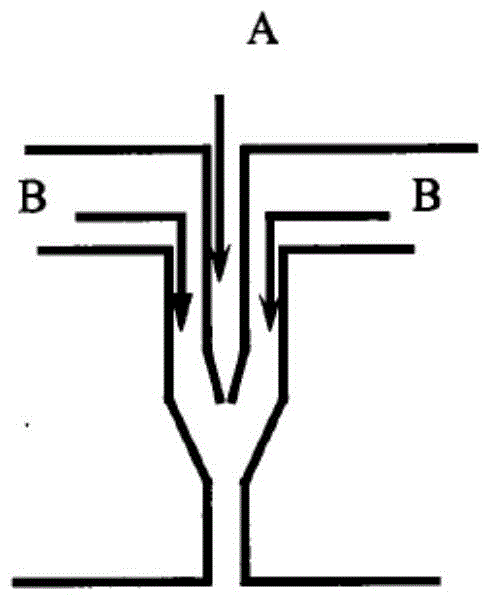

Method used

Image

Examples

Embodiment 1

[0046] Preparation of core material:

[0047] Take 50 mol of polytetrahydrofuran diol with a number-average relative molecular weight of 1000, dehydrate it in vacuum at 105°C for 4 hours, reduce the water content to below 0.5%, and lower the temperature to 60°C; heat 100mol of diphenylmethane diisocyanate (MDI) to 60 ℃ to melt, add to the above vacuum-dried polytetrahydrofuran diol, stir, heat up to 80 ℃ and react for 1 hour to obtain a prepolymer; add 50mol of 1,4-butanediol chain extender to the prepolymer, Mix evenly, then pour into pre-treated molds, mature at 108°C for 20h, and leave at room temperature for 7d to obtain polyurethane.

[0048] Preparation of cortical material:

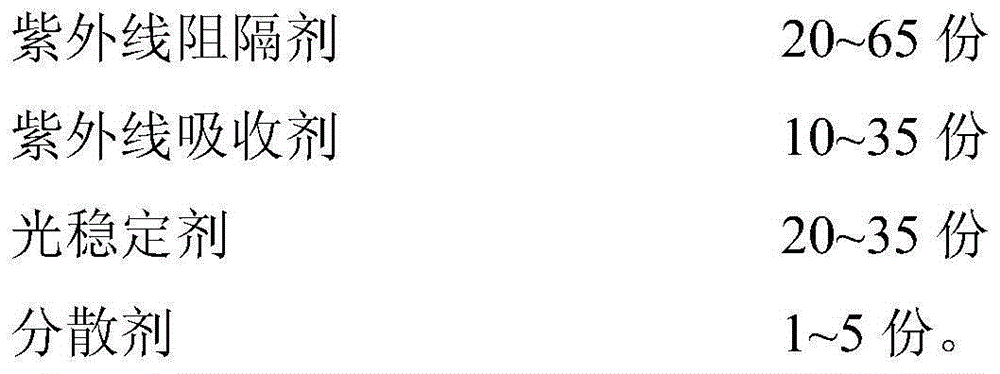

[0049] Get 40 parts by weight of ultraviolet blocking agent titanium dioxide, 15 parts by weight of ultraviolet absorber phenyl hydroxybenzoate, 15 parts by weight of light stabilizer 2,2'-thiobis(4-tert-octylphenoxy) nickel and 2 parts by weight 1 part dispersant sodium polyacrylate, mixed to pr...

Embodiment 2

[0054] Preparation of core material:

[0055] Take 50 mol of polytetrahydrofuran diol with a number-average relative molecular weight of 1000, dehydrate it in vacuum at 105°C for 4 hours, reduce the water content to below 0.5%, and lower the temperature to 60°C; heat 100mol of diphenylmethane diisocyanate (MDI) to 60 ℃ to melt, add to the above vacuum-dried polytetrahydrofuran diol, stir, heat up to 80 ℃ and react for 1 hour to obtain a prepolymer; add 50mol of 1,4-butanediol chain extender to the prepolymer, Mix evenly, then pour into pre-treated molds, mature at 108°C for 20h, and leave at room temperature for 7d to obtain polyurethane.

[0056] Preparation of cortical material:

[0057] Get 40 parts by weight of ultraviolet blocking agent titanium dioxide and 15 parts by weight of ultraviolet absorber phenyl o-hydroxybenzoate, 15 parts by weight of three (1,2,2,6,6-pentamethyl piperidinyl) phosphite and 2 parts by weight The dispersant sodium polyacrylate is mixed to prep...

Embodiment 3

[0062] Preparation of core material:

[0063] Take 50 mol of polytetrahydrofuran diol with a number-average relative molecular weight of 1000, dehydrate it in vacuum at 105°C for 4 hours, reduce the water content to below 0.5%, and lower the temperature to 60°C; heat 100mol of diphenylmethane diisocyanate (MDI) to 60 ℃ to melt, add to the above vacuum-dried polytetrahydrofuran diol, stir, heat up to 80 ℃ and react for 1 hour to obtain a prepolymer; add 50mol of 1,4-butanediol chain extender to the prepolymer, Mix evenly, then pour into pre-treated molds, mature at 108°C for 20h, and leave at room temperature for 7d to obtain polyurethane.

[0064] Preparation of cortical material:

[0065] Get 40 parts by weight of ultraviolet blocking agent titanium dioxide, 15 parts by weight of ultraviolet absorber phenyl phthalate, 15 parts by weight of 2,4,6-three (2-n-butoxyphenyl)-1,3,5-tri Oxyzine and 2 parts by weight of dispersant sodium polyacrylate are mixed to prepare an anti-ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com