Preparation and application of TiO2@MoS2 composite

A composite and product technology, applied in the direction of water pollutants, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of unfavorable visible light catalysis applications, easy aggregation, etc., to achieve catalytic rate, large specific surface area, structure novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

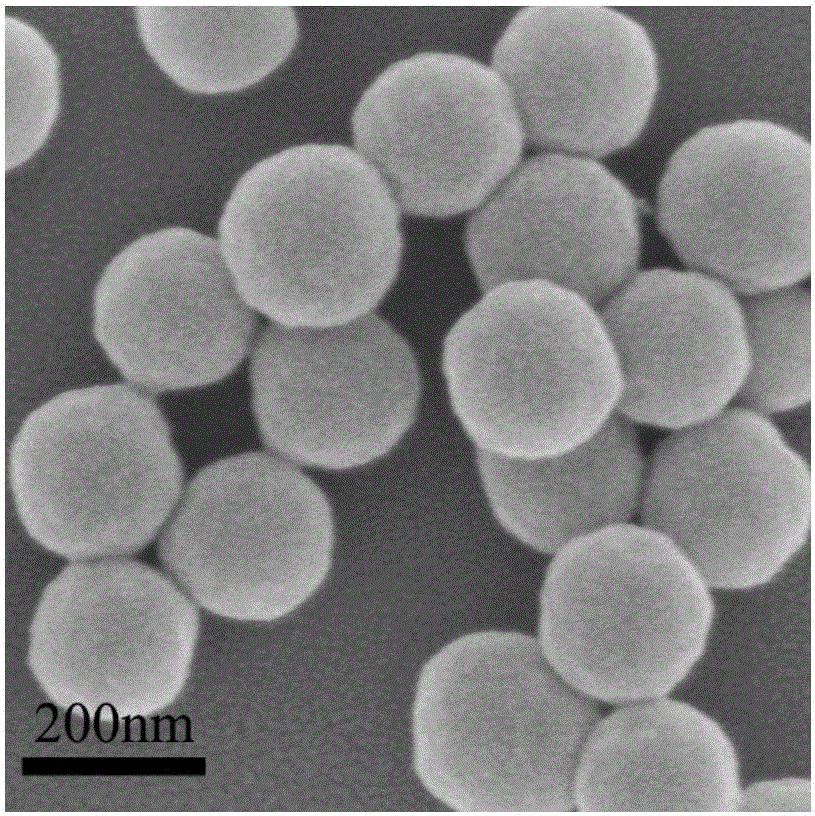

[0023] (1), TiO 2 For the preparation of nanoparticles, prepare 200 mL of a mixture of ethanol and acetonitrile with a volume ratio of 6:1, add 1 mL of deionized water and 0.8 mL of concentrated ammonia water, stir mechanically for 10 min to mix evenly, add 3 mL of tetrabutyl titanate, and stir for 8 h. Wash the product with absolute ethanol for 3 to 5 times, centrifuge at 4000rpm for 10min, and dry in an electric heating constant temperature blast drying oven to obtain white TiO 2 Microspheres. .

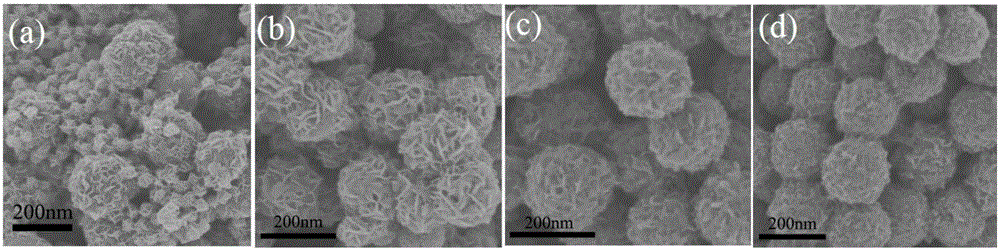

[0024] (2), MoS 2 / TiO 2 Preparation of composite structure, weigh 100mgNa 2 MoO 4 As molybdenum source, 50mgNa 2 S is used as a sulfur source, dissolved in 30mL N-methylpyrrolidone (NMP), ultrasonicated for 40min, and 100mgTiO 2 , transferred to a 50mL polytetrafluoroethylene high-pressure reactor, reacted at 220°C for 24 hours, cooled naturally, washed the product with absolute ethanol 3 to 5 times, centrifuged at 4000rpm for 10min, and dried in an electric heating constan...

Embodiment 2

[0026] (1), TiO 2 For the preparation of nanoparticles, prepare 150 mL of a mixture of ethanol and acetonitrile with a volume ratio of 4:1, add 0.5 mL of deionized water and 1 mL of concentrated ammonia water, stir mechanically for 20 min to mix evenly, add 3 mL of isopropyl titanate, and stir for 8 h. Wash the product with absolute ethanol for 3 to 5 times, centrifuge at 6000rpm for 10min, and dry in an electric heating constant temperature blast drying oven to obtain white TiO 2 powder. .

[0027] (2), MoS 2 / TiO 2 Preparation of composite structure, weigh 200mgNa 2 MoO 4 As molybdenum source, 100mgNa 2 S is used as a sulfur source, dissolved in 30mL dimethylformamide (DMF), ultrasonicated for 100min, and 100mgTiO 2 , transferred to a 50mL polytetrafluoroethylene high-pressure reactor, reacted at 220°C for 48h, cooled naturally, washed the product with absolute ethanol 3 to 5 times, centrifuged at 3000rpm for 10min, and dried in an electric heating constant temperatur...

Embodiment 3

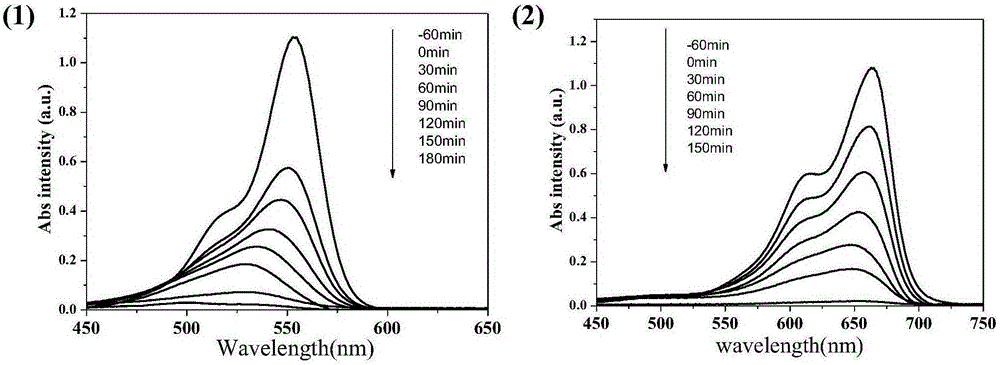

[0030] Photocatalytic degradation of rhodamine B. The photocatalytic experiment was carried out in a CEL-LAX simulated visible light reactor (500W xenon lamp as the light source) produced by Beijing Zhongjiao Jinyuan Technology Co., Ltd., and a 5 mg / L rhodamine B solution was prepared. Accurately weigh 10mg of the product (MoS 2 / TiO 2 Composite structure, surface MoS 2 Content 43%), add this photocatalyst in the quartz test tube, add 100mL above-mentioned rhodamine B solution, ultrasonic dispersion is transferred to and carry out photocatalytic reaction in the simulated visible light reactor. After 60 min, the xenon lamp switch was turned on for the catalytic experiment. Samples of different time periods were taken according to the time required for the reaction. image 3 (1) is the corresponding ultraviolet-visible spectrum diagram. We can see from the diagram that when the amount of catalyst is only 10mg, the dye can be completely catalyzed in only 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Boiling range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com