Manufacturing method for cationic polyelectrolyte and application of cationic polyelectrolyte in super capacitor

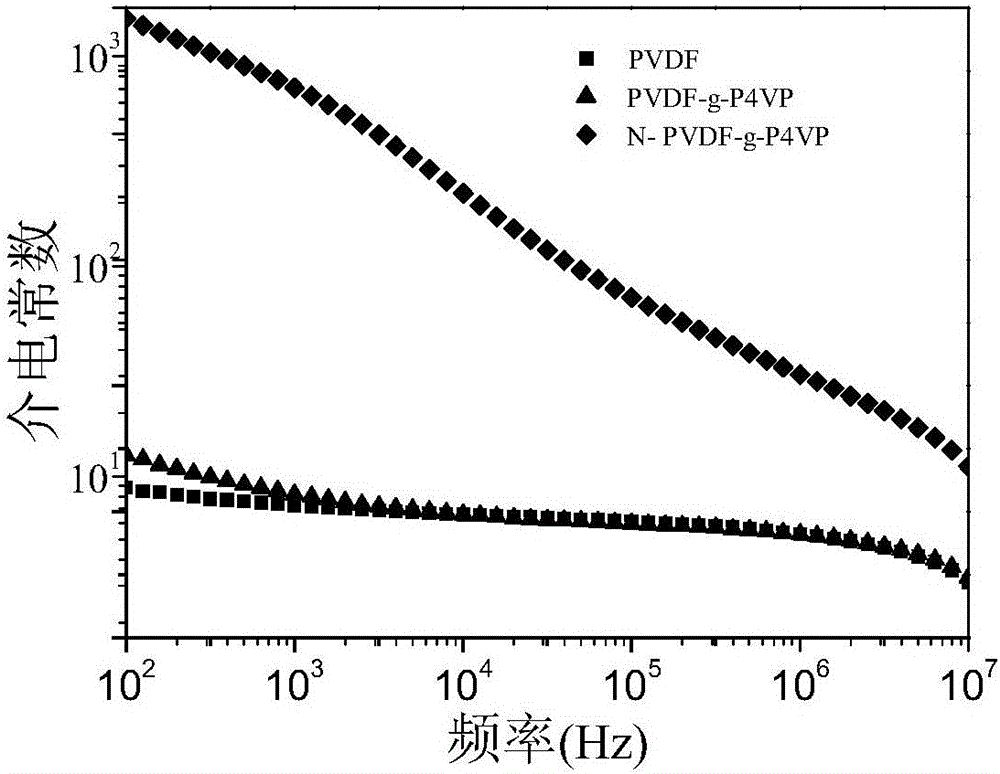

A cationic polymer and cationic polymer technology, applied in the field of polymer materials, can solve the problems of reducing the electrical conductivity of electrodes, reducing the electrochemical energy storage performance of supercapacitors, and high adhesive resistance, achieving high electrical conductivity, high mechanical, high The effect of electrochemical energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

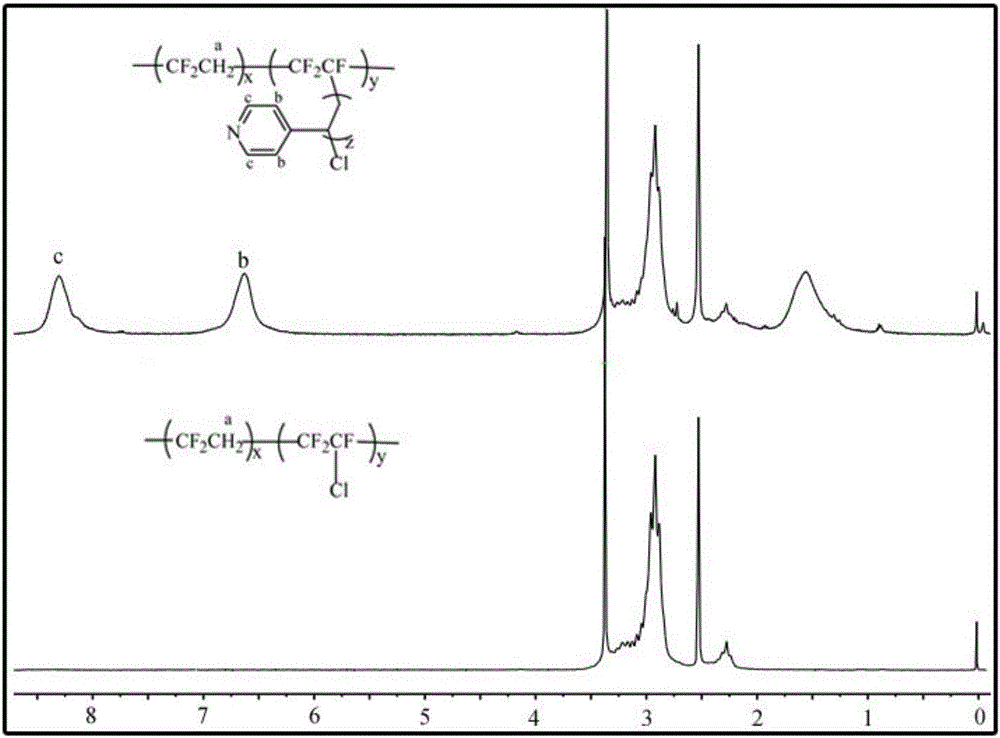

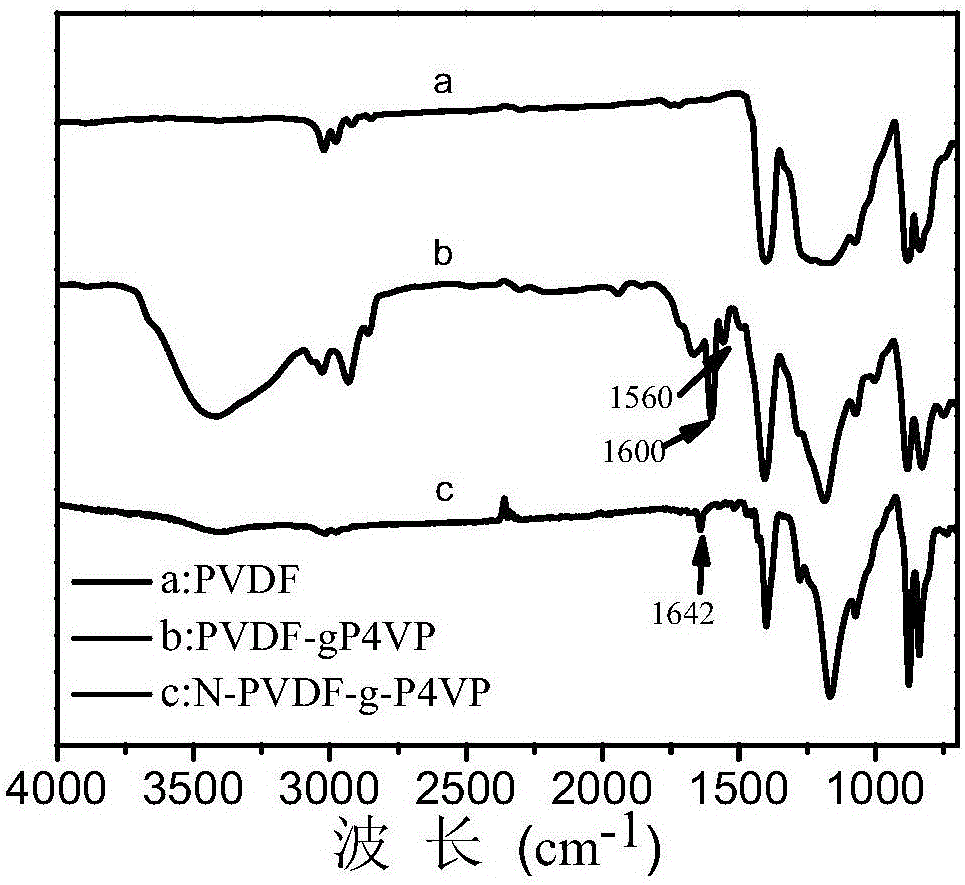

Embodiment 1

[0033] Use an analytical balance to weigh 0.2498g of PVDF into a 50ml Schlenk bottle containing 7.5ml of DMF, stir to dissolve it at 80°C, and quickly add 40mg of CuCl, 110μl of HMTETA, and 1.5ml of 4VP. A branch covered with a rubber tube was sealed and frozen with liquid nitrogen-vacuumed, stirred and melted-filled with nitrogen. This cycle was repeated three times and then completely sealed and placed in an oil bath at 40° C. and stirred for 24 hours. When the reaction is complete, put it in an ice water bath to stop the reaction. The reaction mixture is passed through a neutral aluminum oxide column to remove unreacted catalyst, and the filtrate is dropped into a mixture of methanol and water (the volume ratio of methanol and water is 1:1, stirring while dripping). The homogeneous flocculent polymer was left to stand for two hours and filtered with suction, and dried in a vacuum drying oven at 60°C for 24 hours to obtain the khaki graft polymer (PVDF-g-P4VP). Dissolve 0.2g...

Embodiment 2

[0035] Weigh 0.2468g of PVDF-co-CTFE in a 50ml Schlenk bottle containing 7.5ml of DMF according to Example 1, stir and dissolve it completely at 80°C, and quickly add 40mg of CuCl, 110μl of HMTETA, 1.5ml of 4VP, seal a branch covered with a rubber tube and freeze it with liquid nitrogen-vacuum, stir and melt-fill with nitrogen. This cycle is repeated three times and then completely sealed and placed in an oil bath at 40°C for 18 hours. When the reaction is complete, put it in an ice water bath to stop the reaction. The reaction mixture is passed through a neutral aluminum oxide column to remove unreacted catalyst, and the filtrate is dropped into a mixture of methanol and water (the volume ratio of methanol and water is 1:1, stirring while dripping). The homogeneous flocculent polymer was allowed to stand for two hours and filtered with suction, and dried in a vacuum drying oven at 60°C for 24 hours to obtain a khaki graft polymer (PVDF31508-g-P4VP). Dissolve 0.2g of grafted p...

Embodiment 3

[0037] Weigh 0.2467gP (VDF-TrFE-CTFE) in a 50ml Schlenk flask containing 7.5ml of NMP according to the method in Example 1. Stir and dissolve completely at 80°C, then quickly add 20mg of CuCl, 55μl of HMTETA, 1.5ml of 4VP, seal a branch covered with a rubber tube and freeze it with liquid nitrogen-vacuum and stir to melt-fill with nitrogen. This cycle is repeated three times and then completely sealed and placed in an oil bath at 50°C and stirred for 12 hours. When the reaction is complete, put it in an ice water bath to stop the reaction. The reaction mixture is passed through a neutral aluminum oxide column to remove unreacted catalyst, and the filtrate is dropped into a mixture of methanol and water (the volume ratio of methanol and water is 1:1, stirring while dripping). Homogeneous flocculent polymer, standing for two hours, suction filtration, and drying in a vacuum drying oven at 60°C for 24 hours to obtain a khaki graft polymer (P(VDF-TrFE-CTFE)). Dissolve 0.2g of graf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com