Copper ferrite/graphene quantum dot composite material, and preparation method and application thereof

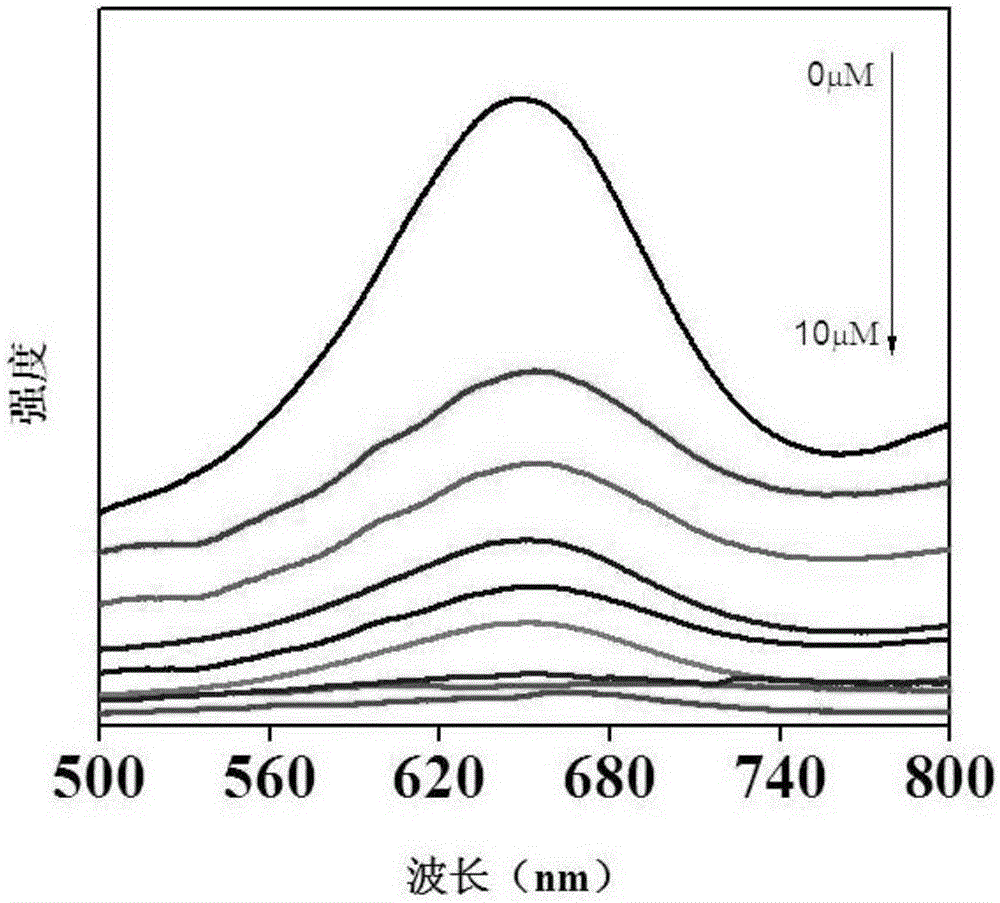

A technology of graphene quantum dots and composite materials, which is applied in the field of copper ferrite/graphene quantum dot composite materials and its preparation and application, and can solve the problems of affecting the sensitivity and precision of pesticide detection, the absorbance value is not high enough, and the color reaction speed is slow and other problems, to achieve good electron transport performance, enhanced catalytic effect, and fast color development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Material preparation

[0037] (1) Preparation of GQDs: Add 2 g of solid citric acid (CA) into a 5 mL beaker, heat to 200 ° C, the citric acid (CA) melts into a liquid, and then the citric acid (CA) liquid changes from colorless to light Yellow, and finally orange liquid. Finally, under vigorous stirring, the 1M NaOH solution was dropped dropwise into the orange liquid until the pH reached 7, and the heating was continued, and finally a GQDs solution was prepared, and the mass of the obtained GQDs solution was m.

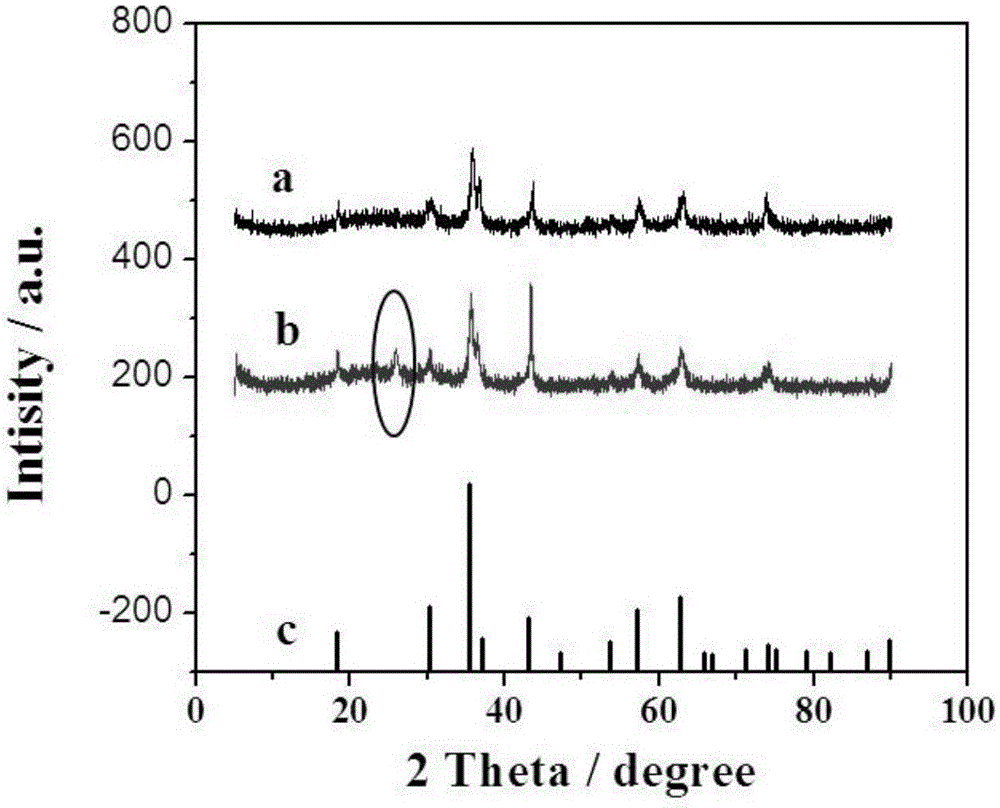

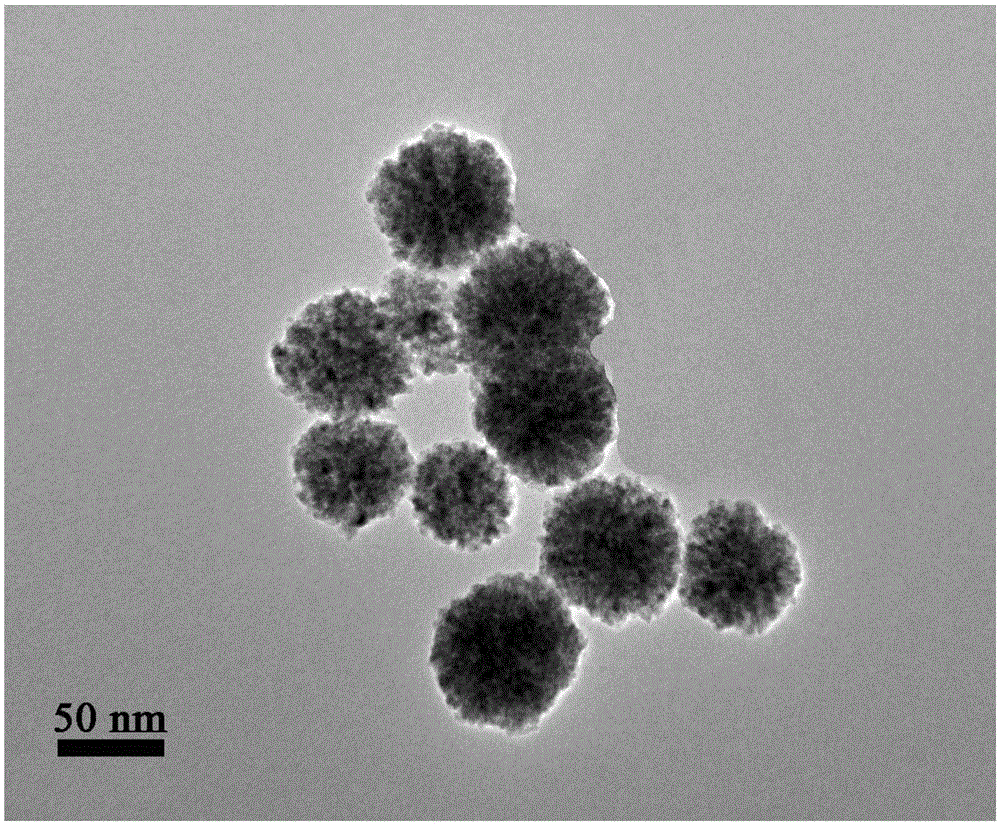

[0038] (2)CuFe 2 o 4 Preparation: First, 0.2025gCuCl 2 ·2H 2 O and 0.4875g FeCl 3 ·6H 2 O was added to 20mL of ethylene glycol (EG), stirred to a transparent solution, then 1.8g of sodium acetate (NaAc) and 0.5g of polyethylene glycol (PEG) were added and stirred for 30min, and loaded into a PTFE reactor with a capacity of 25mL. Heated to 200°C for 8h, cooled to room temperature after reaction to obtain a black product, centrifuged and washed with et...

Embodiment 2

[0046] 1. Material preparation

[0047] (1) Preparation of GQDs: Take 1 g of solid citric acid (CA) into a 5 mL beaker, heat to 150 ° C, the citric acid (CA) melts into a liquid, and then the citric acid (CA) liquid changes from colorless to light Yellow, and finally orange liquid. Finally, under vigorous stirring, the KOH solution with a concentration of 1M was dropped into the orange liquid drop by drop until the pH reached 6, and the heating was continued, and finally a GQDs solution was prepared, and the mass of the obtained GQDs solution was m.

[0048] (2)CuFe 2 o 4 Preparation: First, 0.135gCuCl 2 ·2H 2 O and 0.325 g FeCl 3 ·6H 2O was added to 20mL of ethylene glycol (EG), stirred to a transparent solution, then 1.4g of sodium acetate (NaAc) and 0.3g of polyethylene glycol (PEG) were added and stirred for 30min, and loaded into a PTFE reactor with a capacity of 25mL. Heated to 150°C for 6h, cooled to room temperature after reaction to obtain a black product, cent...

Embodiment 3

[0056] 1. Material preparation

[0057] (1) Preparation of GQDs: Add 4 g of solid citric acid (CA) into a beaker with a volume of 5 mL, heat to 250 ° C, the citric acid (CA) melts into a liquid, and then the citric acid (CA) liquid changes from colorless to light Yellow, and finally orange liquid. Finally, under vigorous stirring, the 1M NaOH solution was dropped dropwise into the orange liquid until the pH reached 8, and the heating was continued, and finally a GQDs solution was prepared, and the mass of the obtained GQDs solution was m.

[0058] (2)CuFe 2 o 4 Preparation: First, 0.27gCuCl 2 ·2H 2 O and 0.65gFeCl 3 ·6H 2 O was added to 20mL of ethylene glycol (EG), stirred to a transparent solution, then 2.2g of sodium acetate (NaAc) and 0.7g of polyethylene glycol (PEG) were added and stirred for 30min, and loaded into a PTFE reactor with a capacity of 25mL. Heated to 250°C for 10h, cooled to room temperature after reaction to obtain a black product, centrifuged and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com