Preparation method of selenium composite electrode material

A composite electrode and composite material technology, applied in the field of electrochemical power supply, can solve problems such as poor product performance, large specific surface area, hidden dangers, etc., and achieve the effects of being conducive to industrial production, simple process, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

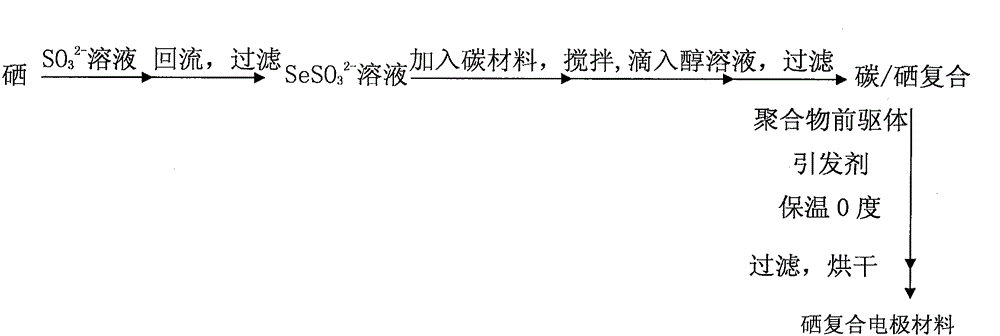

Image

Examples

Embodiment 1

[0023] The composition design of a kind of selenium composite electrode material is:

[0024] Polyaniline, 15wt%; Simple selenium, mass fraction 77%; Graphene, mass fraction 8wt%;

[0025] A preparation method of a selenium composite electrode material: comprising the following steps:

[0026] 1) Weigh a certain mass of sodium sulfite and selenium and mix it with deionized water in a certain proportion, stir evenly: heat to reflux, control the temperature at 100°C, and reflux for 15 hours; obtain sodium selenosulfate; set the molar ratio of sodium sulfite and selenium to 2 :1:

[0027] 2) The product of step 1 is filtered and separated to obtain a sodium selenosulfate solution; dropwise into the ethanol hexane solution in proportion, and stir for 5 hours to obtain a carbon / selenium composite material; set the molar ratio of ethanol to selenium to 1.05; the volume of ethanol and hexane The ratio is 0.1;

[0028] 3) Weigh a certain mass of carbon / selenium composite material m...

Embodiment 2

[0031] The composition design of a kind of selenium composite electrode material is:

[0032] Polyaniline, 15wt%; Simple selenium, mass fraction 73%; Graphite, mass fraction 12wt%;

[0033] Polypyrrole, 15wt%; Selenium, mass fraction 73%; Carbon nanotubes, mass fraction 12wt%;

[0034] Polythiophene, 15wt%; Simple selenium, mass fraction 73%; Carbon black, mass fraction 12wt%;

[0035] A preparation method of a selenium composite electrode material: comprising the following steps:

[0036] 1) Weigh a certain mass of potassium sulfite and selenium and mix it with deionized water in a certain proportion, and stir evenly: heat to reflux, the temperature is controlled at 150°C, and the reflux time is 20h; obtain potassium selenosulfate; set the concentration of potassium sulfite and selenium The molar ratio is 3.5:1:

[0037] 2) The product of step 1 is filtered and separated to obtain a potassium selenosulfate solution; add ethylene glycol benzene solution dropwise in proporti...

Embodiment 3

[0041] The composition design of a kind of selenium composite electrode material is:

[0042] Polyaniline, 20wt%; Simple selenium, mass fraction 75%; Graphene, mass fraction 5wt%;

[0043] Polyaniline, 10wt%; Simple selenium, mass fraction 75%; Graphene, mass fraction 15wt%;

[0044] Polyaniline, 5wt%; Simple selenium, mass fraction 75%; Graphene, mass fraction 20wt%;

[0045] A preparation method of a selenium composite electrode material: comprising the following steps:

[0046] 1) Weigh a certain mass of sodium sulfite and selenium and mix it with deionized water in a certain proportion, and stir evenly: heat to reflux, the temperature is controlled at 120°C, and the reflux time is 20h; obtain sodium selenosulfate; set the molar ratio of sodium sulfite and selenium to 5 :1:

[0047]2) The product of step 1 is filtered and separated to obtain a sodium selenosulfate solution; the aqueous solution of glycerol is added dropwise in proportion, and stirred for 5 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com