Novel method for preparing magnetic microspheres and separating antibody of magnetic microspheres

A technology of magnetic microspheres and a new method, applied in the biological field, can solve the problems of high control requirements of equipment and process parameters, complicated operation in the expanded bed mode, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

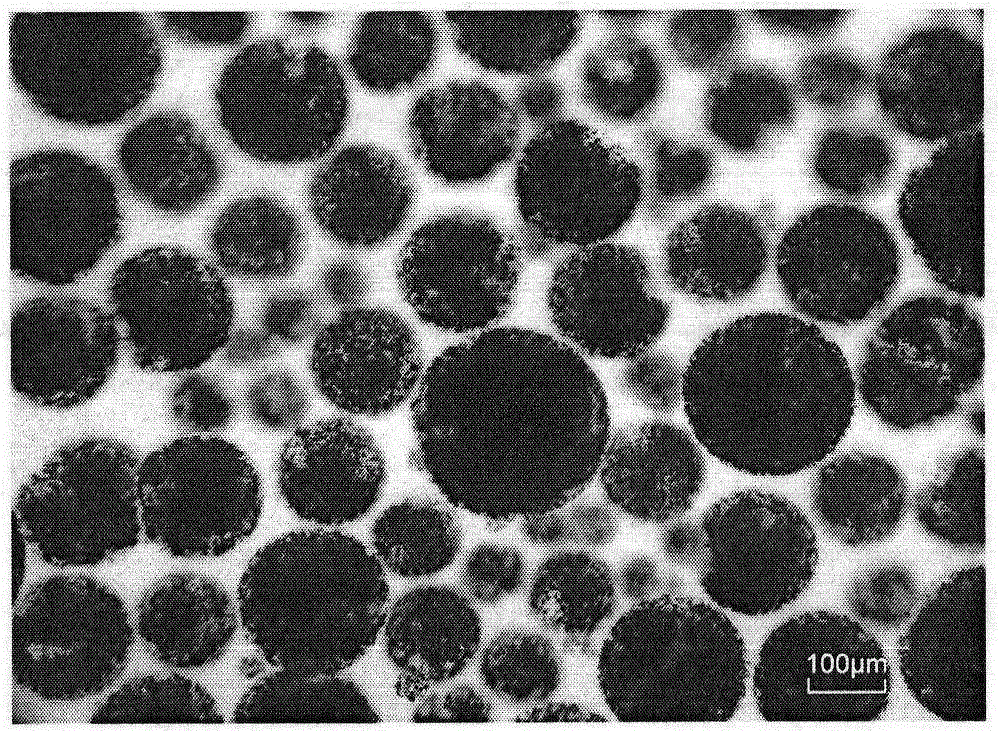

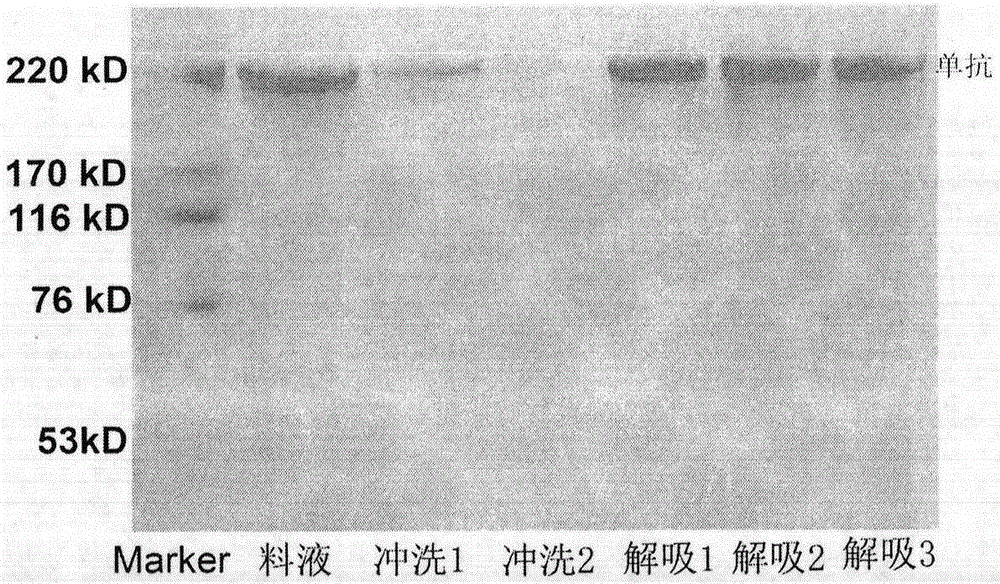

[0022] Weigh 2g of agarose, 1g of nanometer ferric oxide, 1g of sodium chloride and 50g of deionized water, ultrasonically mix and heat to melt the agarose to obtain an aqueous phase; mix the aqueous phase with 324g of vacuum pump oil and 10.8g of Tween Mix at 80°C, stir at high speed at 70°C for 2 hours, place in an ice-water bath to cool down after emulsification, and collect the microspheres; mix 10g of microspheres with 10g of 1M sodium hydroxide and 2g of epichlorohydrin, and shake at room temperature for 1 hour , followed by adding 1g of sodium borohydride, shaking at room temperature for 8 hours to obtain a crosslinked magnetic microsphere matrix; weighing 10g of crosslinked magnetic microspheres, adding 10g of deionized water, 5g of allyl bromide and 5g of sodium hydroxide, Activate by shaking at room temperature for 24 hours, wash with water, 5g N-bromosuccinimide and 30g deionized water, shake at room temperature for 1 hour, wash with water to obtain activated magneti...

Embodiment 2

[0024] Weigh 2g of agarose, 1g of nanometer ferric oxide, 1g of sodium chloride and 50g of deionized water, ultrasonically mix and heat to melt the agarose to obtain an aqueous phase; mix the aqueous phase with 324g of vacuum pump oil and 10.8g of Tween Mix at 80°C, stir at high speed at 70°C for 2 hours, place in an ice-water bath to cool down after emulsification, and collect the microspheres; mix 10g of microspheres with 10g of 1M sodium hydroxide and 2g of epichlorohydrin, and shake at room temperature for 1 hour , followed by adding 1g of sodium borohydride, shaking at room temperature for 8 hours to obtain a crosslinked magnetic microsphere matrix; weighing 10g of crosslinked magnetic microspheres, adding 10g of deionized water, 5g of allyl bromide and 5g of sodium hydroxide, Activate by shaking at room temperature for 24 hours, wash with water, 5g N-bromosuccinimide and 30g deionized water, shake at room temperature for 1 hour, wash with water to obtain activated magneti...

Embodiment 3

[0026]Weigh 2g of agarose, 1g of nanometer ferric oxide, 1g of sodium chloride and 50g of deionized water, ultrasonically mix and heat to melt the agarose to obtain an aqueous phase; mix the aqueous phase with 324g of vacuum pump oil and 10.8g of Tween Mix at 80°C, stir at high speed at 70°C for 2 hours, place in an ice-water bath to cool down after emulsification, and collect the microspheres; mix 10g of microspheres with 10g of 1M sodium hydroxide and 2g of epichlorohydrin, and shake at room temperature for 1 hour , followed by adding 1g of sodium borohydride, shaking at room temperature for 8 hours to obtain a crosslinked magnetic microsphere matrix; weighing 10g of crosslinked magnetic microspheres, adding 10g of deionized water, 5g of allyl bromide and 5g of sodium hydroxide, Activate by shaking at room temperature for 24 hours, wash with water, 5g N-bromosuccinimide and 30g deionized water, shake at room temperature for 1 hour, wash with water to obtain activated magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com