Compound hydrate inhibitor

A hydrate inhibitor, compound technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of large amount of addition, poor inhibition performance, etc., achieve low dosage, excellent performance, and solve the problem of The Effect of Mobile Security Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

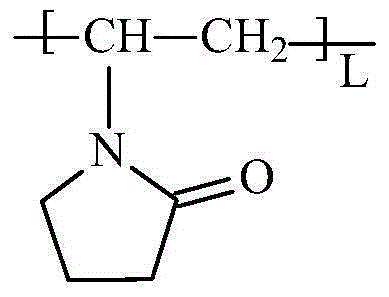

[0050] This example provides a compound hydrate inhibitor, which consists of polyol type nonionic surfactant Span20, PVP (polyvinylpyrrolidone) and TBAB (tetrabutylammonium bromide) in a ratio of 1:1:1 Than mixed to get.

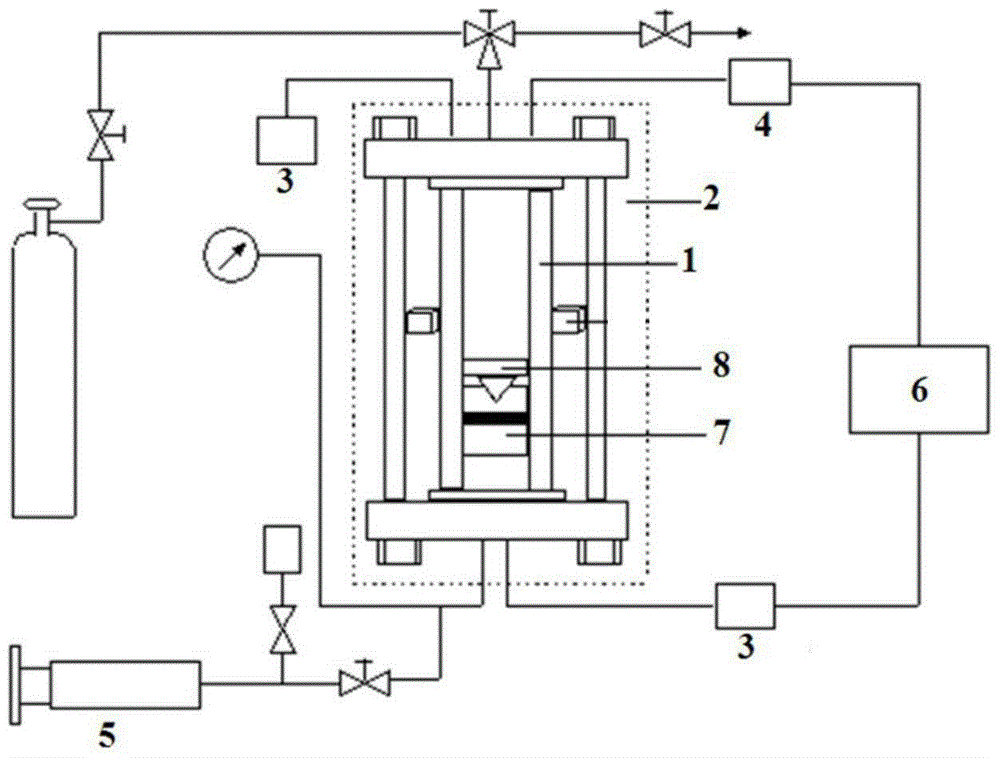

[0051] This embodiment uses the high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 3.0ml deionized water and 12ml of -20# diesel oil, that is, the oil-water system with a water content of 20vol%. The addition amount of type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

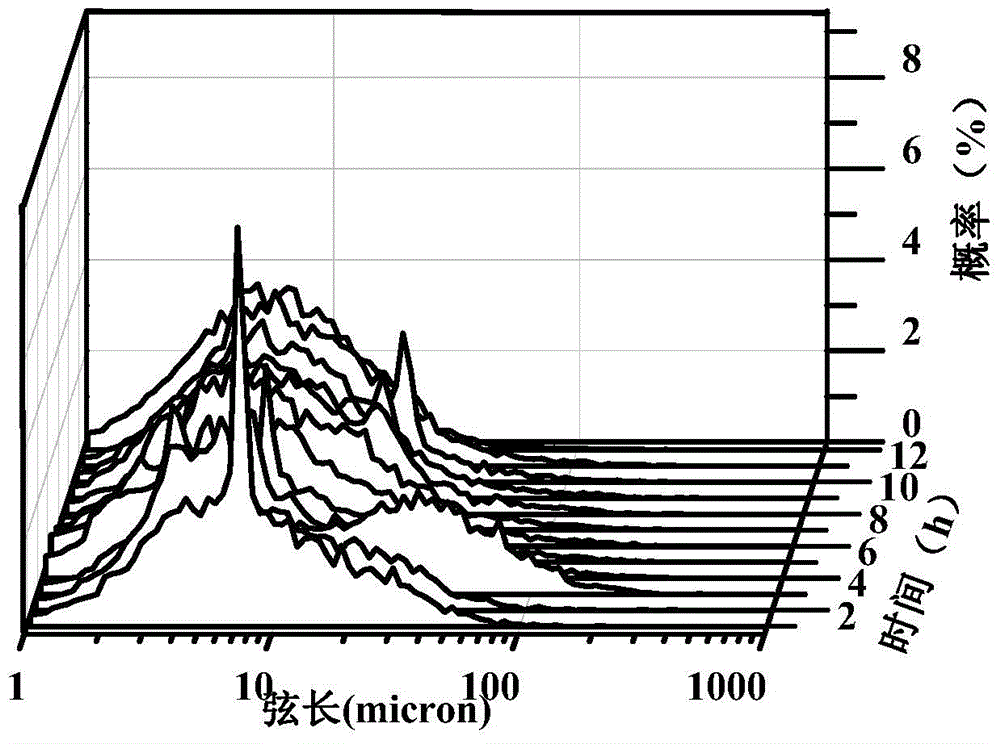

[0052] During the experiment of this example, it was found that the induction time and growth time of hydrate formation could reach 40 minutes and 150 minutes respectively. During the whole experiment, the hydrate particles were evenly dispersed in the oil phase, and no hydrate accumulation occurred after 12 hours of continuous operation. In the case of agglomerat...

Embodiment 2

[0054] This example provides a compound hydrate inhibitor, which consists of polyol-type nonionic surfactant Span20, PVP (polyvinylpyrrolidone) and TBAB (tetrabutylammonium bromide) in a mass ratio of 2:1:1 Than mixed to get.

[0055] This embodiment uses the high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 3.0ml deionized water and 12ml of -20# diesel oil, that is, the oil-water system with a water content of 20vol%. The addition amount of type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

[0056] During the experiment of this example, it was found that the induction time and growth time of hydrate formation could reach 72 minutes and 300 minutes respectively. During the whole experiment, the hydrate particles were evenly dispersed in the oil phase, and no hydrate accumulation occurred after 12 hours of continuous operation. In the case of agglo...

Embodiment 3

[0058] This example provides a compound hydrate inhibitor, which consists of polyol type nonionic surfactant Span40, PVP (polyvinylpyrrolidone) and TBAB (tetrabutylammonium bromide) in a ratio of 1:1:1 Than mixed to get.

[0059] This embodiment uses the high-pressure sapphire reactor for evaluation. The oil-water system in the reactor is composed of 3.0ml deionized water and 12ml of -20# diesel oil, that is, the oil-water system with a water content of 20vol%. The addition amount of type hydrate inhibitor is 2.0% of the water mass in the system, and the experimental gas composition introduced is shown in Table 1.

[0060] During the experiment of this example, it was found that the induction time and growth time of hydrate formation could reach 39 minutes and 194 minutes respectively. During the whole experiment process, the hydrate particles were uniformly dispersed in the oil phase, and no hydrate accumulation occurred after 12 hours of continuous operation. In the case of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com