Cleaning method for nanofiltration membrane and reverse osmosis membrane

A reverse osmosis membrane and nanofiltration technology, which is applied in the cleaning of reverse osmosis membranes and nanofiltration fields, can solve the problems of frequent replacement of nanofiltration membranes and reverse osmosis membrane elements, and achieve easy control of the cleaning operation process, ensure normal operation, and clean The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

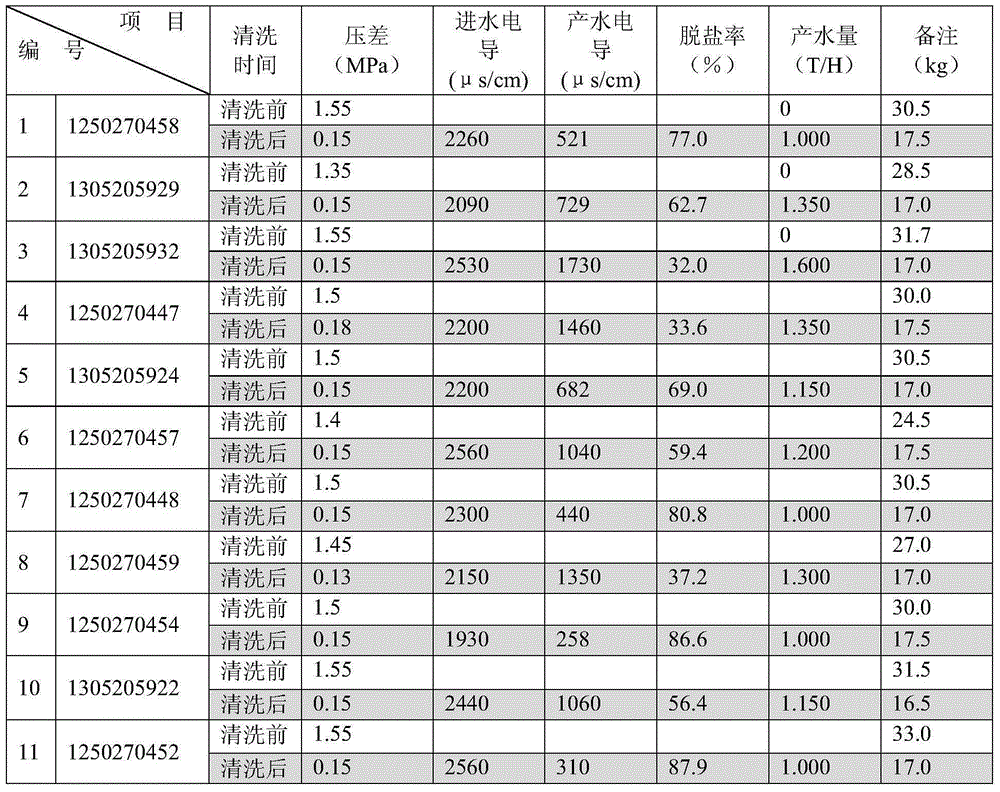

Examples

Embodiment 1

[0044] This embodiment cleans the nanofiltration membrane, including the following steps:

[0045] (1) Test before cleaning: Fill the membrane element to be tested in the pressure vessel of the testing machine, the test solution is 2000ppm MgSO4 solution, the test pressure is 4.8kg / cm2, record the test results; measure the indicators of the membrane element before cleaning: The pressure difference is 1.3Mpa, the influent water conductance is 1580μs / cm, the product water conductance is 500μs / cm, and the water production rate is 0.3T / h. Then put the tested membrane elements into the cleaning machine for cleaning.

[0046] (2) Cleaning with acidic cleaning agent: take a hydrochloric acid cleaning agent with a mass fraction of 0.1%, dilute it with desalinated water to adjust the pH value to 2.2, and turn on the cleaning machine. When the value of the water pressure gauge on the cleaning equipment does not change, the color of the cleaning solution does not change. , When the chan...

Embodiment 2

[0050] This embodiment cleans the nanofiltration membrane, including the following steps:

[0051] (1) Test before cleaning: fill the membrane element to be tested in the pressure vessel of the testing machine, and the test solution is 500ppm CaCl 2 Solution, test pressure 7.0kg / cm2, record the test results; measure the indicators of the membrane element before cleaning: pressure difference 1.4Mpa, influent water conductance 1620μs / cm, product water conductance 496μs / cm, water production 0.4T / h. Then put the tested membrane elements into the cleaning machine for cleaning.

[0052] (2) acid cleaning agent cleaning: get the oxalic acid cleaning agent with a mass fraction of 0.5%, adjust the pH value to 2 by diluting with desalinated water, obtain an acid cleaning agent solution, add the cleaning active agent of 1% of the volume of the above cleaning solution, and then adjust the temperature to 35°C. Turn on the cleaning machine, when the value of the water inlet pressure gauge...

Embodiment 3

[0056] In this embodiment, the reverse osmosis membrane is cleaned, including the following steps:

[0057] (1) Test before cleaning: Fill the membrane element to be tested in the pressure vessel of the testing machine, adjust the conductivity of the test solution to 1500μs / cm with salt, and test the inlet pressure at 15.5kg / cm 2 , the water temperature was adjusted at 25°C, the test results; the indicators of the membrane elements before cleaning were measured: pressure difference 1.2Mpa, influent water conductance 1600μs / cm, product water conductance 520μs / cm, and water production 0.4T / h. Then fill the tested membrane elements in the cleaning machine for cleaning;

[0058] (2) Acid cleaning agent cleaning: get the hydrochloric acid cleaning agent with a mass fraction of 0.1%, adjust the pH value to 2.5 by diluting with desalinated water to obtain an acid cleaning agent solution, add 1% of the cleaning active agent by volume of the above cleaning solution, and then adjust the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com