Carbon nano-material film saturation absorber and preparation method thereof

A technology of carbon nanomaterials and material thin films, which is applied in the field of preparation of ultrashort pulse laser saturable absorbers, can solve the problems of limiting pulse laser output power, achieve high output power, short recovery time, and prevent high temperature oxidation reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

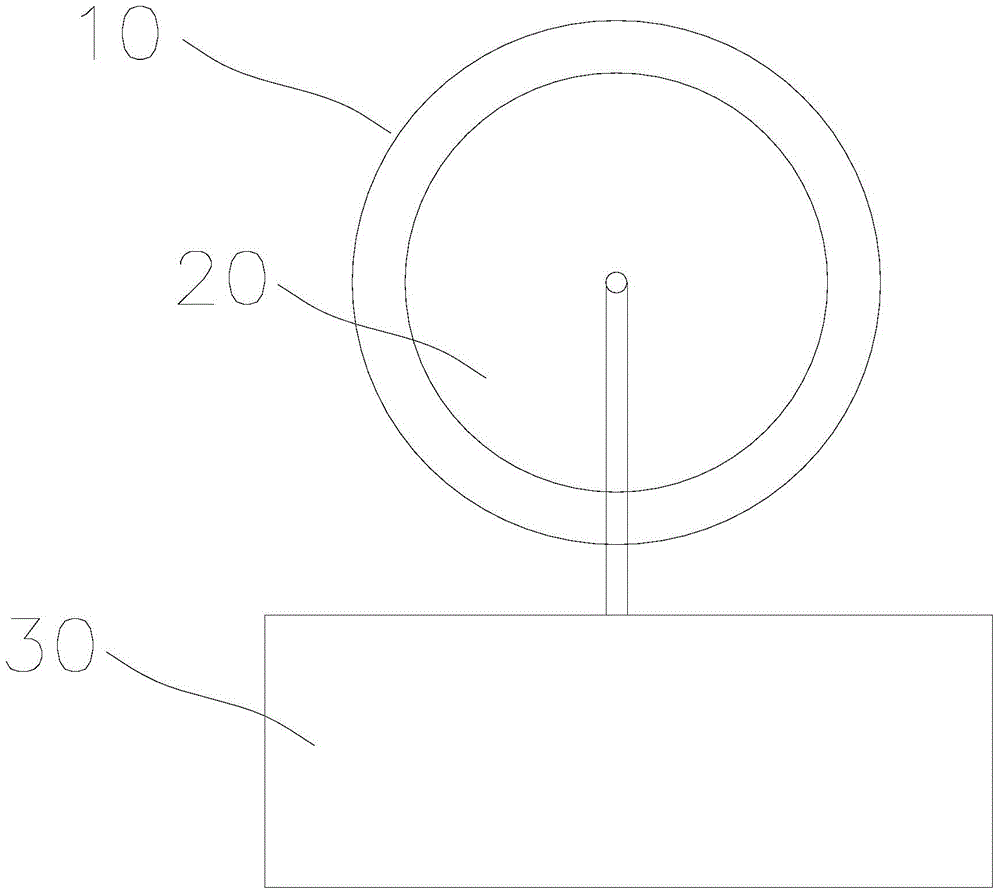

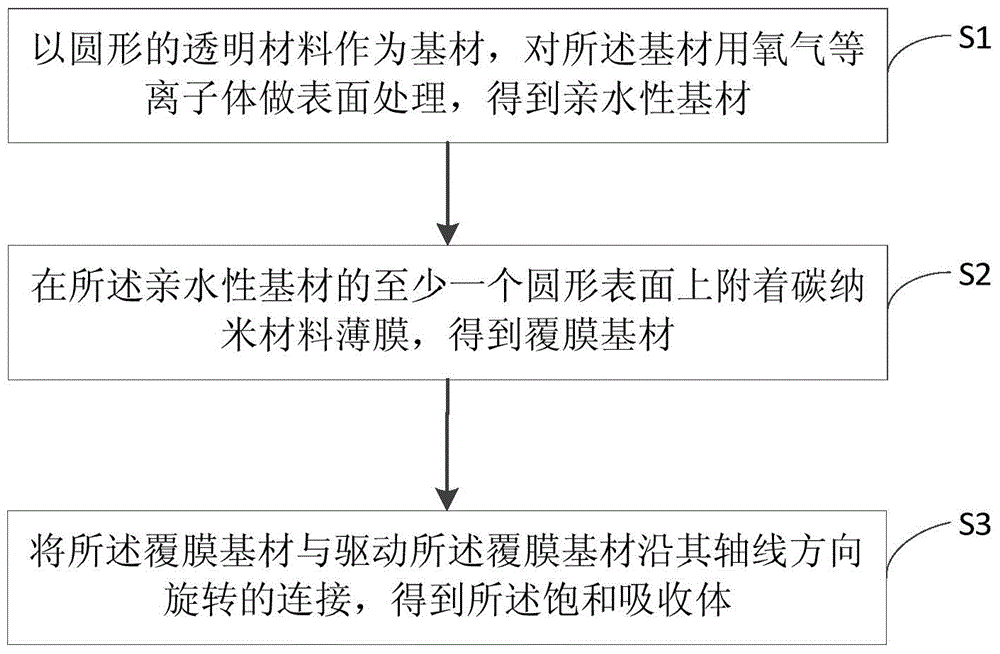

[0085] The invention also provides a method for preparing a carbon nanomaterial film saturated absorber, figure 2 Show the flow chart of the preferred embodiment of the preparation method of carbon nanomaterial thin film saturated absorber of the present invention, as figure 2 Shown, described preparation method comprises the steps:

[0086] S1. Treating the substrate: a circular transparent material is used as the substrate, and the surface of the substrate is treated with oxygen plasma to obtain a hydrophilic substrate. The diameter of the circle is 10mm-100mm, and the height of the circle is 0.5mm-2mm. The transparent material is selected from one of the following materials: quartz, glass, sapphire, silicon carbide crystal, gallium nitride crystal. Surface treatment with oxygen plasma in advance can improve the hydrophilicity of the substrate. The surface treatment process can only treat a circular surface of the film substrate, or the substrate can be treated as a whol...

Embodiment 1

[0092] Ultrasonically disperse the carbon nanotubes in absolute ethanol to form a suspension with a concentration of 0.5mg / ml, use a circular quartz plate with a diameter of 30mm and a thickness of 1mm as the substrate, clean it ultrasonically with acetone, dry it, and then use Oxygen plasma was treated for 60 minutes to improve the hydrophilicity of the surface, and the above-mentioned carbon nanotube suspension was used as a coating solution to prepare a carbon nanotube film by dipping and pulling coating method. The ambient temperature and humidity were 18°C and 40%, respectively. The pulling speed is 96nm / s. Then the prepared film was vacuum dried at 80°C. Finally, the film-coated substrate is installed on the rotating shaft and connected to the driver, which completes the production of the rotation-protecting saturated absorber.

Embodiment 2

[0094] Graphene oxide is ultrasonically dispersed in ethanol to form a suspension with a concentration of 1 mg / ml. A quartz plate with a diameter of 30 mm and a thickness of 0.5 mm is used as a substrate, cleaned ultrasonically with acetone, dried, and then treated with oxygen plasma 60min, improve the hydrophilicity of its surface, use the above-mentioned graphene oxide suspension as the coating solution, and prepare a carbon nanotube film by the spin coating method, and the spin speed is 3000rpm. Then the prepared film was vacuum dried at 80°C. Finally, the film-coated substrate is installed on the rotating shaft and connected to the driver, which completes the production of the rotation-protecting saturated absorber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com