Electrochemical ethyl alcohol sensor based on ethyl alcohol oxidase and preparing method thereof

A technology of alcohol oxidase and sensors, which is applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., can solve problems such as damage and unobvious benefits, and achieve the effects of accurate test results, high selectivity and sensitivity, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

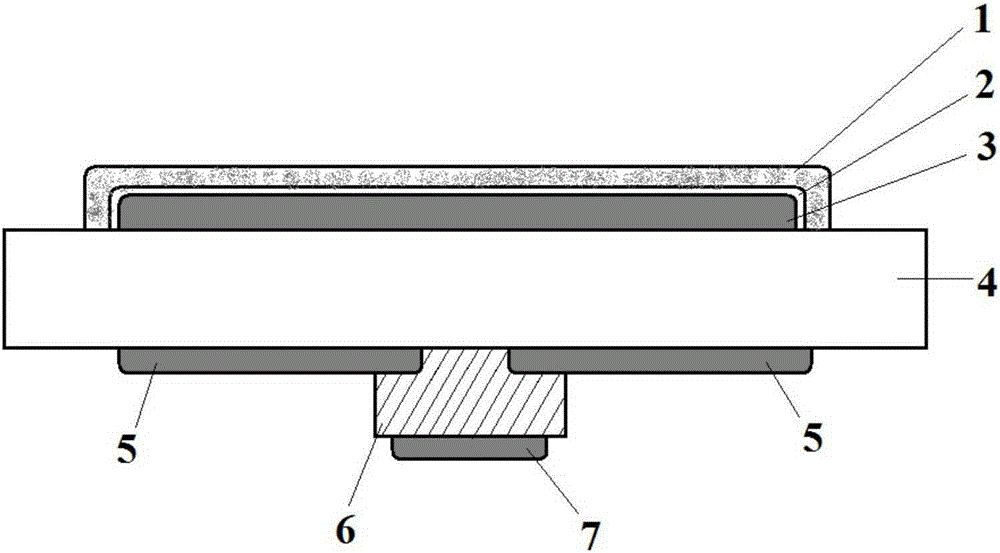

[0027] An electrochemical ethanol sensor based on alcohol oxidase, comprising a substrate and a supporting electrolyte layer 4 arranged on the substrate, a counter electrode 5, a reference electrode 7 and a working electrode 3, the working electrode 3 and the counter electrode 5 and the reference electrode 3 The ratio electrodes 7 are all separated, and the working electrode 3 is covered with an alcohol oxidase layer 1, and the alcohol oxidase layer 1 is made of an electrically insulating biologically active material on which the alcohol oxidase is carried. ) obtained on an electrically insulating bioactive layer, an auxiliary diffusion layer 2 is provided between the working electrode 3 and the alcohol oxidase layer 1, and an auxiliary diffusion layer 2 is arranged between the alcohol oxidase layer 1 and the working electrode 3. A partially interpenetrating network structure is formed and tightly combined; ethanol generates acetaldehyde under the action of alcohol oxidase, and...

Embodiment 2

[0037] A preparation method of the described electrochemical ethanol sensor based on ethanol oxidase, the method comprises the following steps: 1. preparation of electrodes: a working electrode, a counter electrode and a reference electrode are arranged at one end of the substrate, and A supporting electrolyte layer is set on the chip; the supporting electrolyte layer 4 is a polymer solid electrolyte layer, so as to avoid the electrolyte from contaminating the alcohol oxidase layer and causing the enzyme layer to be inactivated. More preferably, the polymer solid electrolyte layer includes perfluorosulfonic acid At least one of ion exchange resin, polystyrene sulfonic acid / salt solid electrolyte, sulfonated polypropylene, sulfonated polyether sulfone, potassium polyethylene sulfonate and sodium polyacrylate; ② preparation of auxiliary diffusion layer: in the working electrode printing or spraying the slurry of the auxiliary diffusion layer to obtain the auxiliary diffusion laye...

Embodiment 3

[0039] Embodiment 3: the preparation method of ethanol sensor

[0040] ①A supporting electrolyte layer is set on a porous nitrocellulose substrate with a length of 45mm and a width of 10mm, and a conductive carbon black electrode is printed on one end of the porous nitrocellulose substrate as a working electrode and a counter electrode, and silver- A silver chloride electrode was used as a reference electrode.

[0041] On the reference electrode, between the working electrode and the counter electrode, an electrolyte layer (non-supporting electrolyte) is printed, and its main component is: a polyurethane hydrogel layer containing KCl0.1M.

[0042] ②Print the slurry of the auxiliary diffusion layer on the working electrode, and its main components are emulsion-like polytetrafluoroethylene and auxiliary materials; wherein, emulsion-like polytetrafluoroethylene (surfactant removal) 100g, auxiliary materials are polytetrafluoroethylene 5g of butyl acrylate, 25ml of terpineol, 800...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com