Asphalt composite matrix flexible waterproof coiled material, and preparation method thereof

A flexible waterproof and asphalt technology, applied in the direction of asphalt layered products, chemical instruments and methods, building insulation materials, etc., to achieve the effects of enhancing peeling performance, improving compatibility, and improving low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

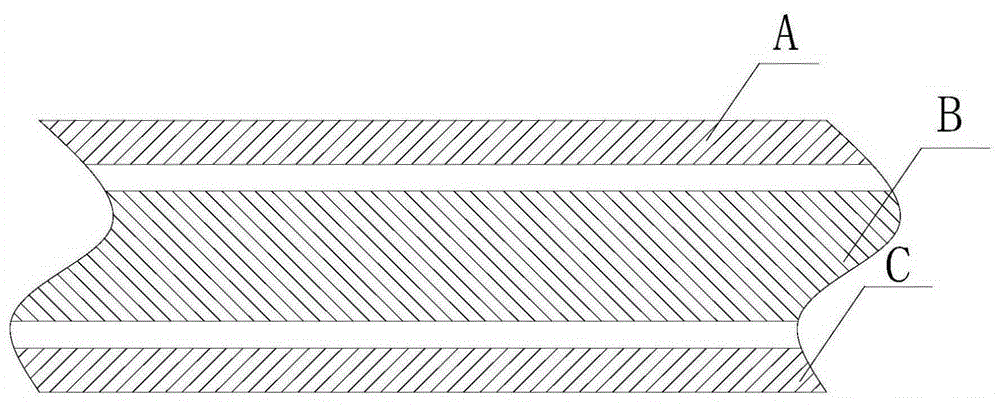

[0024] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an asphalt composite tire flexible waterproof membrane proposed by the present invention.

[0025] refer to figure 1 , a kind of asphalt composite tire flexible waterproof roll material proposed by the present invention, comprises base layer B, the upper surface layer A bonded on the base layer B and the lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the tire base layer The base layer B is bonded with modified asphalt, the base layer B and the lower surface layer C are bonded with modified asphalt, the base layer B is made of non-woven fabric, and the upper surface layer A is made of polyethylene film, high temperature resistant polyester film or thin Sand is made, and the lower surface layer C is made of polyethylene film.

[0026] The preparation method of modified asphalt comprises the steps:

[0027] S1. Add 2 parts of epichlorohydrin and 2 par...

Embodiment 2

[0032] A kind of asphalt composite tire flexible waterproof coiled material proposed by the present invention comprises a base layer B, an upper surface layer A bonded on the base layer B and a lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B is bonded with modified asphalt, base layer B and lower surface layer C are bonded with modified asphalt, base layer B is made of non-woven fabric, and upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand The lower surface layer C is made of polyethylene film.

[0033] The preparation method of modified asphalt comprises the steps:

[0034]S1. Add 5 parts of epichlorohydrin and 1 part of hydrogen peroxide to 8 parts of acetone in parts by weight to obtain a mixed solution; add 50 parts of straw powder to 30 parts of sulfuric acid solution with a concentration of 2mol / L and heat up to 105°C, stirring After 5 hours, add the mixe...

Embodiment 3

[0039] A kind of asphalt composite tire flexible waterproof coiled material proposed by the present invention comprises a base layer B, an upper surface layer A bonded on the base layer B and a lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B is bonded with modified asphalt, base layer B and lower surface layer C are bonded with modified asphalt, base layer B is made of non-woven fabric, and upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand The lower surface layer C is made of polyethylene film.

[0040] The preparation method of modified asphalt comprises the steps:

[0041] S1. Add 3 parts of epichlorohydrin and 1.8 parts of hydrogen peroxide to 6.5 parts of acetone in parts by weight to obtain a mixed solution; add 60 parts of straw powder to 22 parts of sulfuric acid solution with a concentration of 4mol / L and heat up to 115°C, stirring After 3.8 hours, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com