Degradable repair stent used for urethra and ureter and preparation methods

A ureter and urethra technology, applied in the field of degradable repair stents and preparation, achieves good mechanical properties, broad market application prospects, and reduces pain and surgical risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

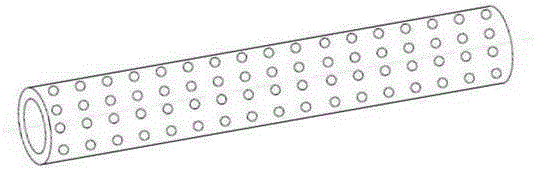

[0025] The porous magnesium urethra and ureter repair scaffolds of ZK60 magnesium alloy with external diameters of 3mm, 5mm and 8mm were prepared by machining method. The preparation steps are as follows:

[0026] (1) First, the as-cast ZK60 magnesium alloy is subjected to heat treatment before machining, and the treatment process is homogenization annealing at 400° C. for 13 hours. Then an extruder is used to extrude the cast magnesium alloy into a rod shape. The extrusion ratio is at most 50.

[0027] (2) Using a machining center, process the extruded magnesium alloy rods into cylinders with an outer diameter of 3 mm, 5 mm, and 8 mm and a height of 20 mm. Then use the micro-drilling equipment to uniformly drill through holes with a diameter of 0.5mm along the radial direction of the cross-sectional circle of the magnesium alloy bar.

[0028] (3) For the porous magnesium rod that has penetrated through the micropores, use drilling equipment to drill long holes with diamete...

Embodiment 2

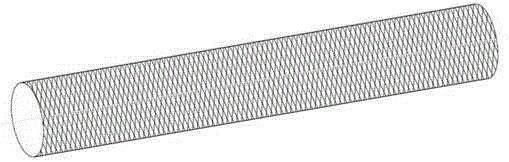

[0032] The porous magnesium urethral and ureter repair scaffolds with wall thickness of 0.5 mm, 1 mm and tube diameters of 3 mm, 5 mm, and 8 mm were prepared by network weaving method. The preparation steps are as follows:

[0033] (1) First, high-purity magnesium is prepared into high-toughness magnesium wires with diameters of 0.5mm and 1mm by using a special drawing process.

[0034] (2) The high-purity magnesium wire is woven into a high-purity magnesium wire mesh according to the standard of 0.5mm between the wires.

[0035] (3) The prepared magnesium wire mesh is rolled into a porous network pipe according to the diameter of 3mm, 5mm, 8mm and the size of 20mm in length. And weld and fix the contact points of the magnesium wires everywhere. Porous magnesium scaffolds were fabricated after electrochemical polishing.

[0036] The porous magnesium urethral and ureteral stents prepared by the network weaving method have denser pores and thinner stent walls. According to t...

Embodiment 3

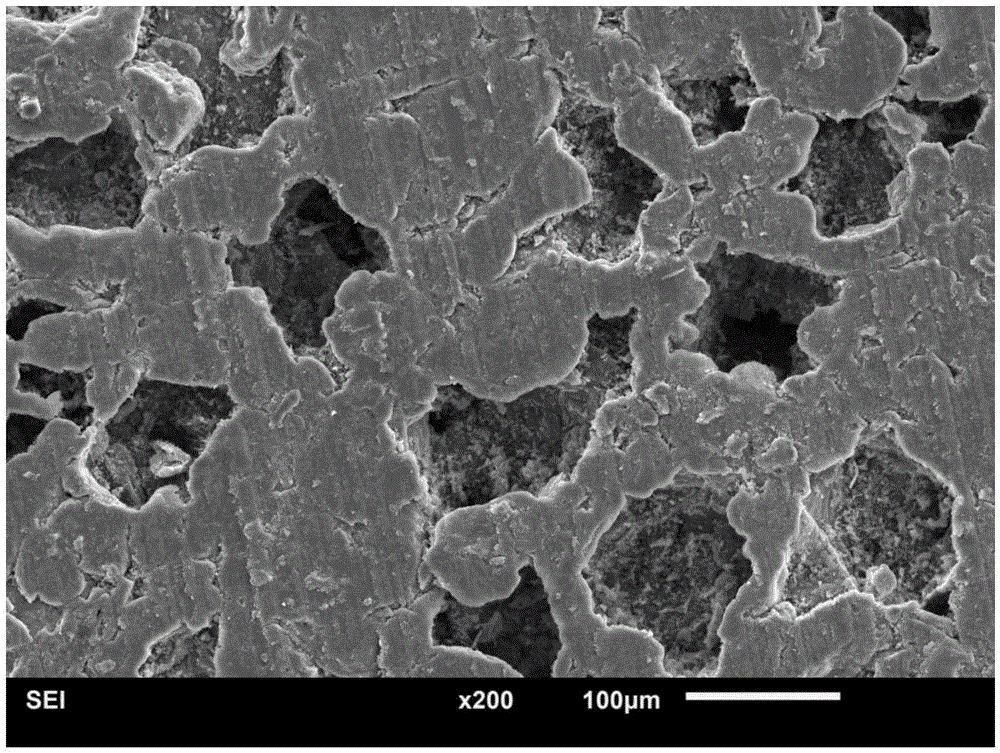

[0039] High-purity magnesium porous urethra and ureteral repair brackets with tube outer diameters of 3mm, 5mm, and 8mm and inner diameters of 1.5mm, 3mm, and 6mm were prepared by laser ablation. The preparation steps are as follows:

[0040] (1) First select high-purity magnesium, and after heat treatment that meets the requirements, use a high-precision machining center to process pure magnesium rods with a diameter of 3mm, 5mm, 8mm and a length of 20mm.

[0041] (2) Using a precision laser processing device, micropores of 50-100 μm are evenly etched on the surface of the high-purity magnesium rod, and the final porosity is guaranteed to be 40%.

[0042] (3) Finally, holes with inner diameters of 1.5mm, 3mm, and 6mm were ablated along the central axis by laser. The final porous magnesium scaffold was prepared after electrochemical polishing.

[0043] The porous magnesium urethra and ureter stents are prepared by laser ablation, a very precise processing method, and the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com