Supported transition metal phosphide catalyst, preparation method and application thereof

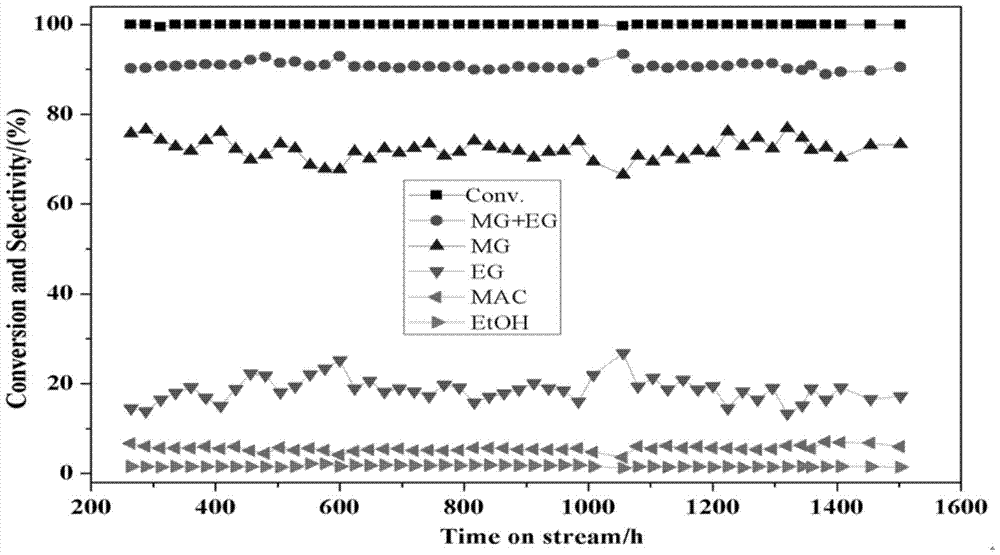

A transition metal and catalyst technology, applied in the field of supported transition metal phosphide catalyst and its preparation, can solve the problems of poor stability, increased catalyst production cost, easy aggregation and deactivation of copper-based catalyst, etc., and achieves good stability and production cost. Low effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

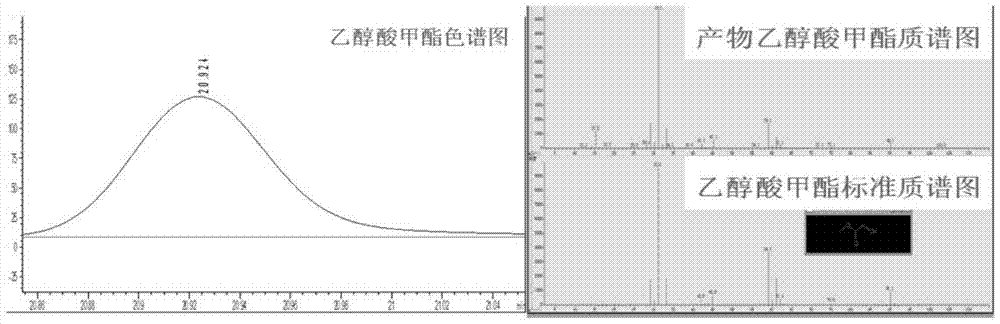

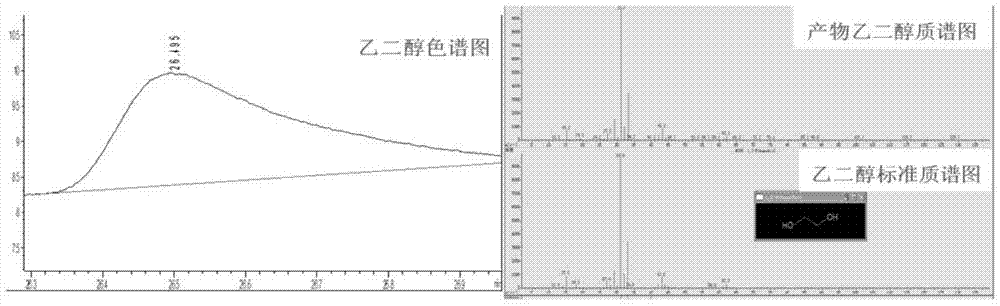

Examples

Embodiment 1

[0048] 1) Weigh 7.7g of nickel nitrate and 3.5g of diammonium hydrogen phosphate, add them into 23ml of deionized water to form a precipitate, add 2.4ml of nitric acid dropwise within 6min to dissolve the precipitate, and obtain an impregnation solution;

[0049] 2) impregnate an equal volume of 14g SiO with the impregnating solution obtained in step 1) 2 on the carrier, placed at room temperature for 8 hours, dried at 110°C for 14 hours, and calcined at 420°C for 3 hours to obtain the catalyst precursor;

[0050] 3) The catalyst precursor obtained in step 2) is heated to 550°C at a heating rate of 4°C / min in a hydrogen atmosphere to perform a reduction reaction, and H 2 The airspeed is 2000h -1 , treated at constant temperature for 3 hours, after the reaction was completed, the temperature was cooled to room temperature, and 1v% O 2 / N 2 Mixed gas passivation treatment for 4 hours to obtain the supported transition metal phosphide catalyst provided by the present invention...

Embodiment 2

[0058] 1) Weigh 14.5g of nickel nitrate and 6.6g of diammonium hydrogen phosphate, add them into 18ml of deionized water to form a precipitate, add 4.5ml of nitric acid dropwise within 12min to dissolve the precipitate, and obtain an impregnating solution;

[0059] 2) impregnating an equal volume of 31 g of ZnO carrier with the impregnating solution obtained in step 1), placing it at room temperature for 4 hours, drying at 110°C for 12 hours, and roasting at 400°C for 5 hours to obtain a catalyst precursor;

[0060] 3) The catalyst precursor obtained in step 2) is heated to 600 ° C at a heating rate of 2 ° C / min in a hydrogen atmosphere to perform a reduction reaction, H 2 The airspeed is 2500h -1 , treated at constant temperature for 3 hours, after the reaction was completed, the temperature was lowered to room temperature, and 1% O 2 / N 2 Mixed gas passivation treatment for 4 hours to obtain the supported transition metal phosphide catalyst provided by the present invent...

Embodiment 3

[0069] 1) Weigh 9.73g of nickel nitrate and 4.42g of diammonium hydrogen phosphate, add them into 14ml of deionized water to form a precipitate, add 3ml of nitric acid dropwise within 8min to dissolve the precipitate, and obtain an impregnation solution;

[0070] 2) impregnate an equal volume of 18.5g TiO with the impregnating solution obtained in step 1) 2 on the carrier, placed at room temperature for 7 hours, dried at 110°C for 9 hours, and calcined at 480°C for 4 hours to obtain the catalyst precursor;

[0071] 3) The catalyst precursor obtained in step 2) is heated to 650°C at a heating rate of 1°C / min in a hydrogen atmosphere to perform a reduction reaction, and H 2 The airspeed is 3600h -1 , treated at a constant temperature for 4 hours, after the reaction was completed, the temperature was cooled to room temperature, and 1v% O 2 / N 2 Mixed gas passivation treatment for 4 hours to obtain the supported transition metal phosphide catalyst provided by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com