production c 2‑10 Alkanediol method

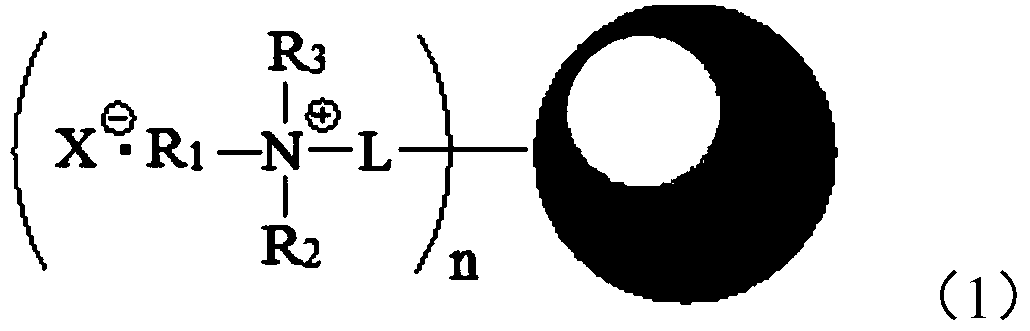

A technology of alkanediol and branched chain alkyl, which is applied in the field of production of C2-10 alkanediol, and can solve problems such as easy loss of active components and poor catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Magnetic Fe 3 o 4 Preparation of nanoparticles: 14.12g Fe(acac) 3 Dissolve in a mixed solution composed of 200mL oleylamine and 200mL dibenzyl ether, treat the solution at 110°C for 1 hour under the protection of nitrogen, then continue to treat it at 300°C for 2 hours under the protection of nitrogen, add 100mL of ethanol, and centrifuge to obtain The solid was washed 3 times with 100 mL of acetone, and the obtained solid was dried in a vacuum oven to obtain magnetic Fe 3 o 4 The nanoparticle A1 was characterized by a transmission electron microscope, and it was found that the average particle size of the nanoparticle was 9.5 nm.

[0082] Treatment of chlorosilicate: 10.0g magnetic Fe 3 o 4Nanoparticles A1 were placed in a 500mL three-necked bottle, and then 200mL of anhydrous toluene, 2.0g of γ-chloropropyl triethoxysilane (γ-chloropropyl triethoxysilane, CPTES, C 3 h 6 ClSi(OC 2 h 5 ) 3 ), reflux at 110°C for 24 hours, filter, wash with absolute ethanol for...

Embodiment 2

[0086] Magnetic Fe 3 o 4 Preparation of nanoparticles: 14.12g Fe(acac) 3 Dissolve in a mixed solution composed of 400mL oleylamine and 50mL dibenzyl ether, treat the solution at 80°C under nitrogen protection for 5 hours, then continue to treat it at 350°C under nitrogen protection for 4 hours, add 100mL of ethanol, and centrifuge to obtain The solid was washed 3 times with 100 mL of acetone, and the obtained solid was dried in a vacuum oven to obtain magnetic Fe 3 o 4 The nanoparticle A2 was characterized by a transmission electron microscope, and it was found that the average particle diameter of the nanoparticle was 5.9 nm.

[0087] Treatment of chlorosilicate: 10.0g magnetic Fe 3 o 4 Nanoparticles A2 were placed in a 500mL three-necked bottle, and then 200mL of anhydrous toluene, 0.2g γ-chloropropyl triethoxysilane (γ-chloropropyl triethoxysilane, CPTES, C 3 h 6 ClSi(OC 2 h 5 ) 3 ), refluxed for 6 hours, filtered, washed 3 times with absolute ethanol, and dried i...

Embodiment 3

[0091] Magnetic Fe 3 o 4 The preparation method of nanoparticle A2 is the same as [Example 2], and the process of chlorosilicate treatment is the same as [Example 1], except that the chlorosilicate used is CPTMS: 3-chloropropyl trimethoxysilane (3-chloropropane Trimethoxysilane), the structural formula is ClC 3 h 6 Si(OCH 3 ) 3 , the carrier B3 was obtained, and after weighing, it was found that the chlorosilicate and magnetic Fe on B3 3 o 4 The weight ratio of nanoparticles is 0.069.

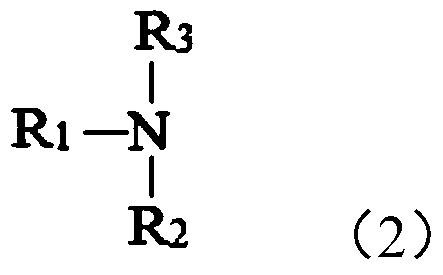

[0092] The quaternization process is the same as that described in [Example 1], except that the tertiary amine used is tributylamine, and the obtained Cl-type loaded quaternary ammonium salt C3 is obtained.

[0093] Cl - The transformation of the supported quaternary ammonium salt of the type is the same as the process described in [Example 1] to obtain catalyst D3, wherein the weight content of the quaternary ammonium salt component is 11.2%, and the rest is a carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com