A method for producing aerated concrete with water-quenched copper tailings after copper selection and iron extraction

A technology for aerated concrete and copper tailings is applied in the field of solid waste treatment and utilization and tailings production of aerated concrete. , The effect of improving final strength and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

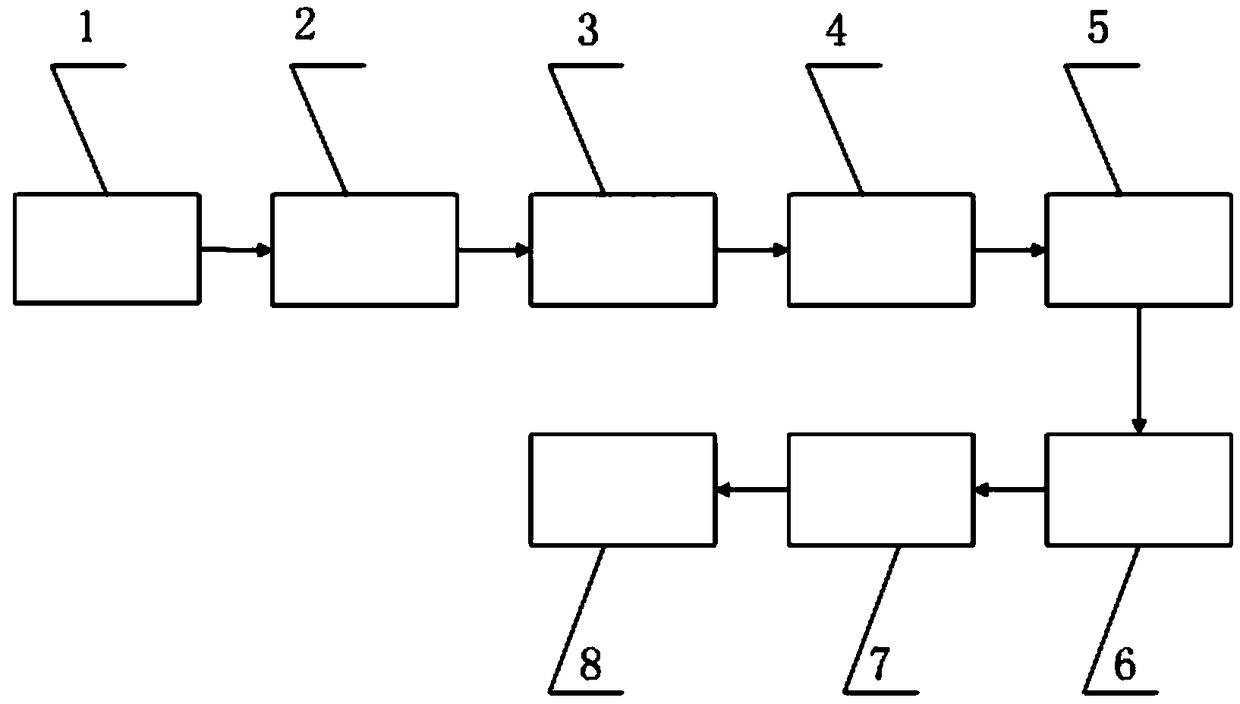

Method used

Image

Examples

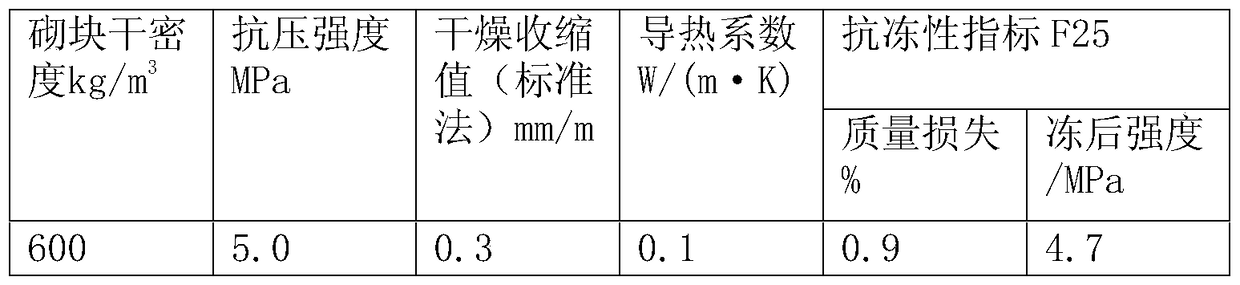

example 1

[0030] 1. After the water-quenched copper slag accumulated in the copper smelter is subjected to the flotation process for secondary copper selection, and after the rotary kiln high-temperature reduction and firing process for magnetic separation to extract iron, the remaining tailing slag composition requirements are: TFe (full iron) is 8 %, Cu is 0.07%, SiO 2 45%, CaO 30%, Al2 o 3 S is 3.4%, S is 0.1%, and C content is 1%. The particle size of copper tailings is less than 74 μm (200 mesh) and accounts for 95%. After iron extraction, the concentration of copper tailings pulp is usually kept at 60%. It can be directly crushed into the pulping tank; the lime is crushed and ground to 200 mesh, accounting for 95%, and then transported into the lime slurry tank for pulping; the silica sand with a particle size of 3mm is selected and directly made into mortar without any treatment process.

[0031] 2. Transport copper slag, silica sand, lime, and cement into the mixing tank accord...

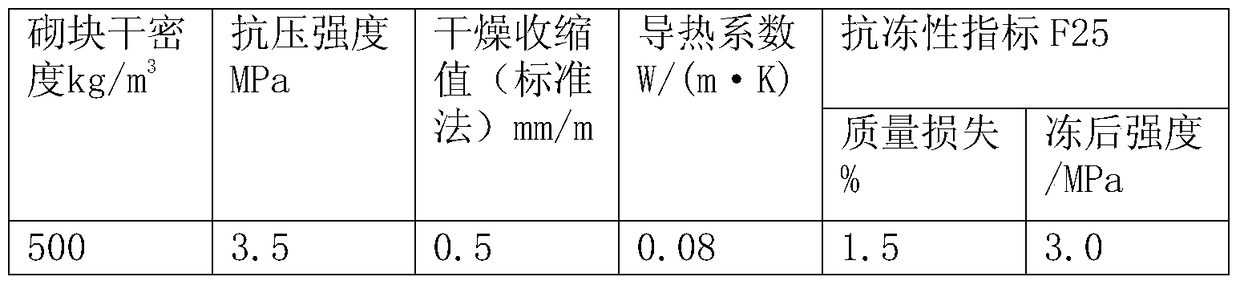

example 2

[0042] 1. After the water-quenched copper slag accumulated in the copper smelter is subjected to the flotation process for secondary copper selection, and the rotary kiln high-temperature reduction and firing process for magnetic separation to extract iron, the remaining tailing slag composition requirements are: TFe (full iron) is 9 %, Cu is 0.05%, SiO 2 48%, CaO 30%, Al 2 o 3 S is 3.3%, S is 0.1%, and C content is 1%. The particle size of copper tailings is less than 74μm (200 mesh) and accounts for 90%. Pour into the slurry tank without dehydration treatment process; the lime is conventionally crushed and ground to 200 mesh, accounting for more than 95%, and sent into the lime slurry tank for pulping; the ordinary silica sand with a particle size of 2‐4mm is selected and directly produced without any treatment process mortar.

[0043] 2. Convey copper slag, silica sand, lime and cement into the mixing tank for mixing according to weight percentage. The weight percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com