Separating purifying method for ingenol extract

A technology for the separation and purification of ingenol, which is applied in the field of extraction and separation of traditional Chinese medicine, can solve the problems of lower yield, lower production yield, and long time consumption, and achieve the effects of reducing reagent consumption, reducing the amount of silica gel used, and shortening the hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The separation and purification method of embodiment 1 ingenol extract

[0067] Take 10 kg of Gansui decoction pieces, and use 95% ethanol to reflux extract for 3 times. For the first time, 100L was added for reflux extraction for 2 hours, for the second time, 80L was added for reflux extraction for 1 hour, and for the third time, 80L was added for reflux extraction for 1 hour, and the extracts were combined and concentrated under reduced pressure to extract.

[0068] Dilute the extracted extract to 5L with methanol, stir well to fully dissolve, then add 25g of potassium hydroxide, stir and hydrolyze for 12 hours, then add hydrochloric acid to adjust the pH to 7 to terminate the hydrolysis, and the hydrolyzate is concentrated under reduced pressure to an extract;

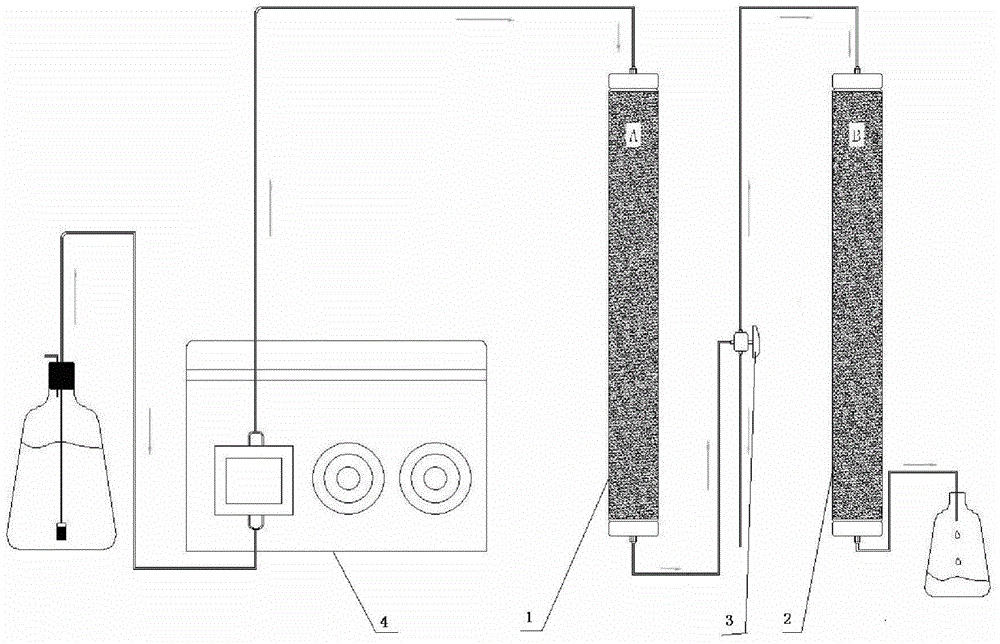

[0069] Select chromatographic columns A and B (10×100cm) of the same specification, press figure 1 As shown in the connection, first adjust the three-way valve to disconnect the chromatography column A and B...

Embodiment 2

[0071] The separation and purification method of embodiment 2 ingenol extract

[0072] Take 50kg of Stephania chinensis, crush it, and extract it 3 times with methanol under reflux. For the first time, 400L was added for reflux extraction for 2 hours, for the second time, 300L was added for reflux extraction for 1.5 hours, and for the third time, 300L was added for reflux extraction for 1.5 hours. The extracts were combined and concentrated under reduced pressure to extract.

[0073] Dilute the above extracted extract to 30L with absolute ethanol, stir well to fully dissolve, then add 300g of sodium hydroxide, stir and hydrolyze for 16 hours, then add phosphoric acid to adjust the pH to 7 to terminate the hydrolysis, and the hydrolyzate is concentrated under reduced pressure to extract. ;

[0074] Select chromatographic columns A and B (20×60cm) of the same specification, press figure 1 For the connection shown, first adjust the three-way valve to disconnect the chromatograp...

Embodiment 3

[0076] The separation and purification method of embodiment 3 ingenol extract

[0077] Take 200 kg of Stephania chinensis, crush it, and extract it 3 times with methanol under reflux. Add 1600L reflux extraction for 2 hours for the first time, add 1200L reflux extraction for 1.5 hours for the second time, add 1200L reflux extraction for 1.5 hours for the third time, combine the extracts, and concentrate under reduced pressure to an extract;

[0078] Dilute the extracted extract with methanol to 80L, stir well to fully dissolve, then add 2.4kg of sodium methoxide, stir and hydrolyze for 16 hours, then add hydrochloric acid to adjust the pH to 7 to terminate the hydrolysis, and the hydrolyzate is concentrated under reduced pressure to an extract;

[0079] Select chromatographic columns A and B (23×150cm) of the same specification, press figure 1 For the connection shown, first adjust the three-way valve to disconnect the chromatography column A and B. The chromatography column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com