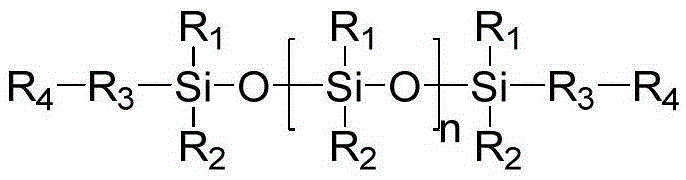

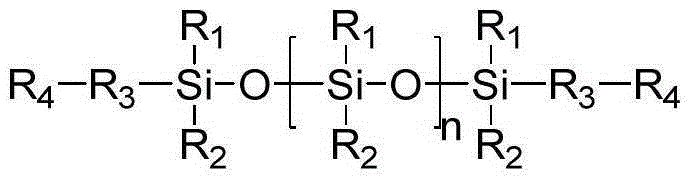

Organic silicon polyurethane/urea anti-fouling material bonded with anti-fouling factor and preparation and application thereof

An antifouling factor, silicone technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, biocide-containing paints, etc., can solve the problem of low surface energy, low elastic modulus of silicone coatings, impact on Marine ecological environment and other issues, to achieve the effect of good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

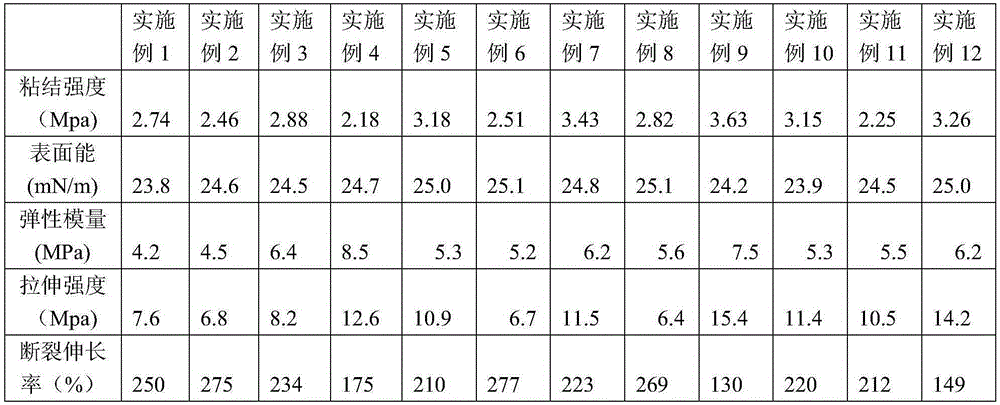

Examples

Embodiment 1

[0045] In a three-neck flask equipped with a mechanical stirrer, a reflux condenser and a temperature detector, add 30.50 g of α, ω-hydroxy polydimethylsiloxane (molecular weight 5000), and vacuumize at 120°C for 2 hours to remove water and low-boiling small molecules Then close the vacuum and feed argon, cool to 60°C, add 65mL tetrahydrofuran, stir (speed 500rpm) to dissolve; then add 23.95g diphenylmethane diisocyanate (MDI), 0.80g dibutyltin dilaurate, argon Under protection, stir and react at 300rpm for 30 minutes; add 3.30g of dihydroxycarantine, 6.80g of 1,4-butanediol, continue to stir and react for 4h to obtain a silicone polyurethane / urea bonded with an antifouling active factor antifouling material. The obtained antifouling material of organic silicon polyurethane / urea bonded with antifouling active factors was coated on an epoxy glass fiber board, and no marine organisms grew on the shallow sea hanging board for 8 months.

Embodiment 2

[0047] Add 61.35 g of α, ω-hydroxypropyl polydimethylsiloxane (molecular weight 3000) to a three-necked flask equipped with a mechanical stirrer, reflux condenser, and temperature probe, and vacuumize at 120°C for 2 hours to remove water and small molecules Low boilers, then close the vacuum and feed argon, cool down to 80°C, add 150mL xylene, stir (speed 400rpm) to dissolve; then add 30.25g toluene diisocyanate (TDI), 5.12g stannous octoate, under argon protection , stirring and reacting at 300rpm for 10 minutes; adding 5.15g of paeonol and 5.65g of ethylene glycol, and continuing to stir and react for 6h to discharge, to obtain an antifouling material of silicone polyurethane / urea bonded with antifouling active factors. The obtained antifouling material of silicone polyurethane / urea bonded with antifouling active factors was coated on an epoxy glass fiber board, and no marine organisms grew on the shallow sea hanging board for 6 months.

Embodiment 3

[0049] Add 92.00 g of α, ω-hydroxybutyl polydimethylsiloxane (molecular weight: 2000) to a three-neck flask equipped with a mechanical stirrer, reflux condenser, and temperature detector, and vacuumize at 120°C for 2 hours to remove water and small molecules Low boilers, then turn off the vacuum and feed argon, cool down to 100°C, add 420mL N,N-dimethylacetamide, stir at a speed of 100rpm, dissolve; then add 32.35g of lysine diisocyanate (LDI), 3.5g Dibutyltin dilaurate, under the protection of argon, stirred and reacted at 100rpm for 40 minutes; added 13.42g of N-(2,4,6-trichlorophenyl) maleimide, 1.75g of dihydroxy The amine was stirred and reacted for 3 hours to discharge the material, and an antifouling material of organic silicon polyurethane / urea bonded with an antifouling active factor was obtained. The obtained antifouling material of organic silicon polyurethane / urea bonded with antifouling active factors is coated on an epoxy glass fiber board, and no marine organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com