Three-component acid bright copper plating additive and application thereof in electroplating process and electrolytic copper foil manufacturing process

An electroplating process and electrolytic copper foil technology, which are applied in the technical field of acid bright copper plating and electrolytic copper foil preparation, can solve the problems that dye additives are not resistant to high temperature, gelatin additives are easy to be hydrolyzed and fail, and achieve excellent mechanical properties, easy to control, The effect of uniform and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Equipped with basic electrolyte - 1L aqueous solution of copper sulfate and sulfuric acid, in which Cu 2+ 90g / L, H 2 SO 4 100g / L. Add 40 mg chloride ion, 15 mg sodium phenyldithiopropanesulfonate and 40 mg nonylphenol ethoxylate 15 to 1 L of basic electrolyte.

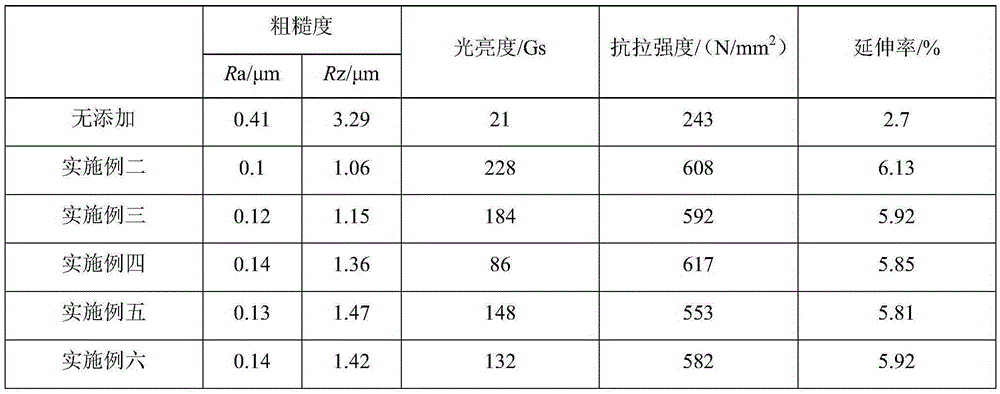

[0030] Control the temperature of the electrolyte at 50°C, the stirring speed is 30r / min, the copper plate is used as the anode, the electroless copper-plated plastic plate is used as the cathode, and the constant current density is 700mA / cm 2 Electroplating for 0.5min. The copper plating on the surface of the plastic plate is bright and flat, and the surface roughness of the coating is Ra=0.14 μm and Rz=1.48 μm measured by a roughness tester; the brightness of the coating is 132Gs when tested by a metal gloss meter.

Embodiment 2

[0032] Equipped with basic electrolyte - 1L aqueous solution of copper sulfate and sulfuric acid, in which Cu 2+ 90g / L, H 2 SO 4 100g / L. Add 50 mg of chloride ion, 10 mg of sodium phenyldithiopropanesulfonate and 30 mg of nonylphenol ethoxylate 40 to 1 L of basic electrolyte.

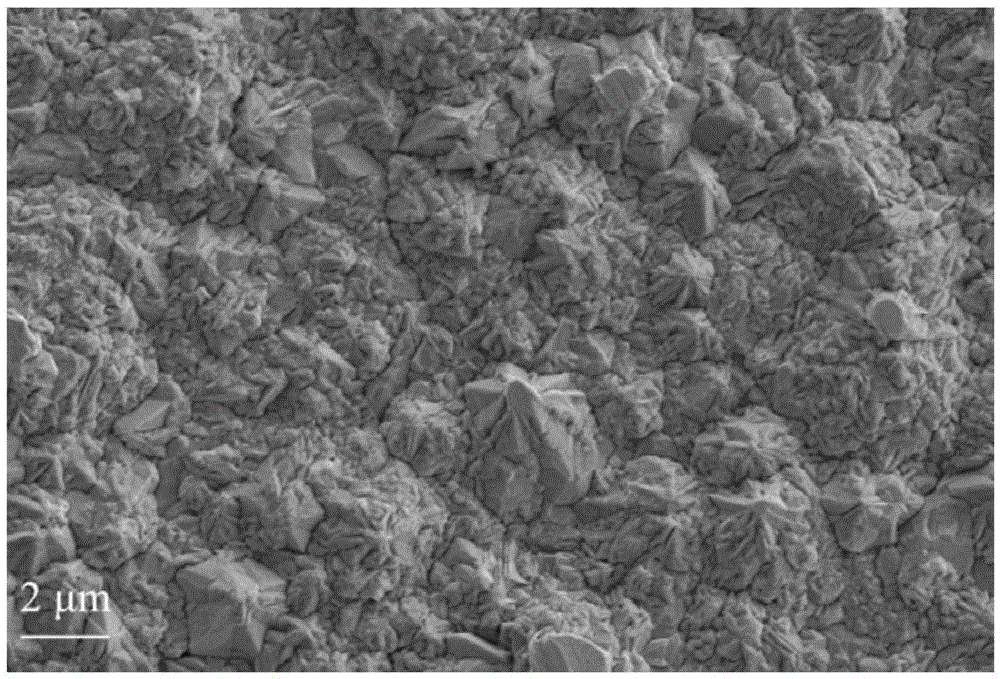

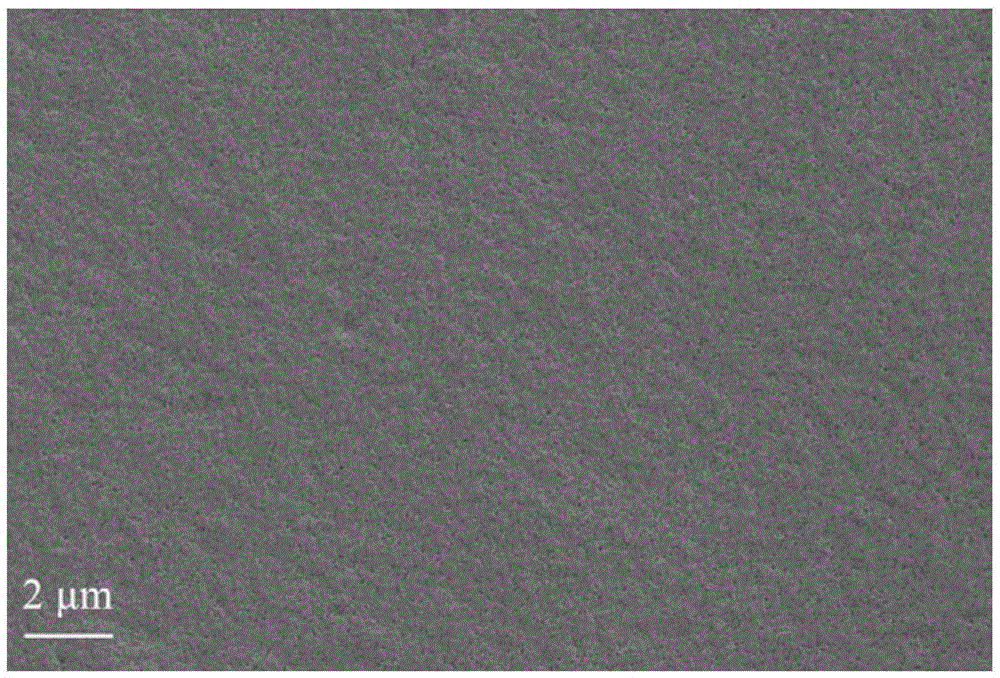

[0033] Control the temperature of the electrolyte at 55°C, stir at a speed of 30r / min, use titanium as the anode, and use a titanium roller with a diameter of 10cm as the cathode, keep the rotation speed of the titanium roller at 20r / min, and use a constant current density of 750mA / cm 2 Bright copper foil was obtained by electrolysis. In order to intuitively understand the performance of additives, copper foil without additives was prepared under the same electroplating process, and the morphology of the obtained copper foil was observed with a field emission scanning electron microscope. The density is 750mA / cm2 The SEM image of the prepared electrolytic copper foil is as follows figure 1 As shown;...

Embodiment 3

[0036] Equipped with basic electrolyte - 1L aqueous solution of copper sulfate and sulfuric acid, in which Cu 2+ 90g / L, H 2 SO 4 100g / L. Add 50 mg of chloride ion, 10 mg of sodium phenyldithiopropanesulfonate, 20 mg of nonylphenol ethoxylate 10 and 10 mg of nonylphenol ethoxylate 40 into 1 L of basic electrolyte.

[0037] Control the temperature of the electrolyte at 55°C, stir at a speed of 30r / min, use titanium as the anode, and use a titanium roller with a diameter of 10cm as the cathode, keep the rotation speed of the titanium roller at 20r / min, and use a constant current density of 750mA / cm 2 Electrolysis to obtain bright copper foil. The roughness and brightness of the copper foil were tested with a roughness tester and a metal gloss meter respectively, and the tensile strength and elongation of the copper foil were tested with a universal tensile testing machine. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com