Copper sulfide microtube in special shape and preparation method and application thereof

A copper sulfide and micro-tube technology, applied in copper sulfide and other directions, can solve the problems of increased preparation cost, human and environmental hazards, and difficult to control the appearance, and achieve the effects of favorable catalytic performance, stable performance and high crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

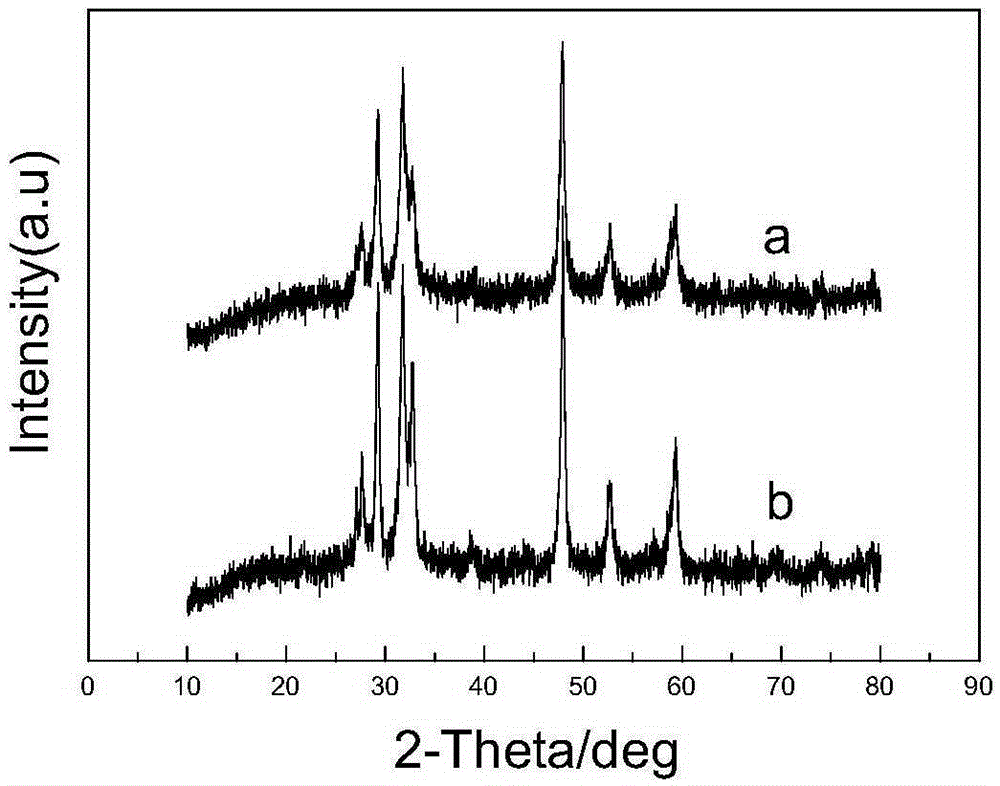

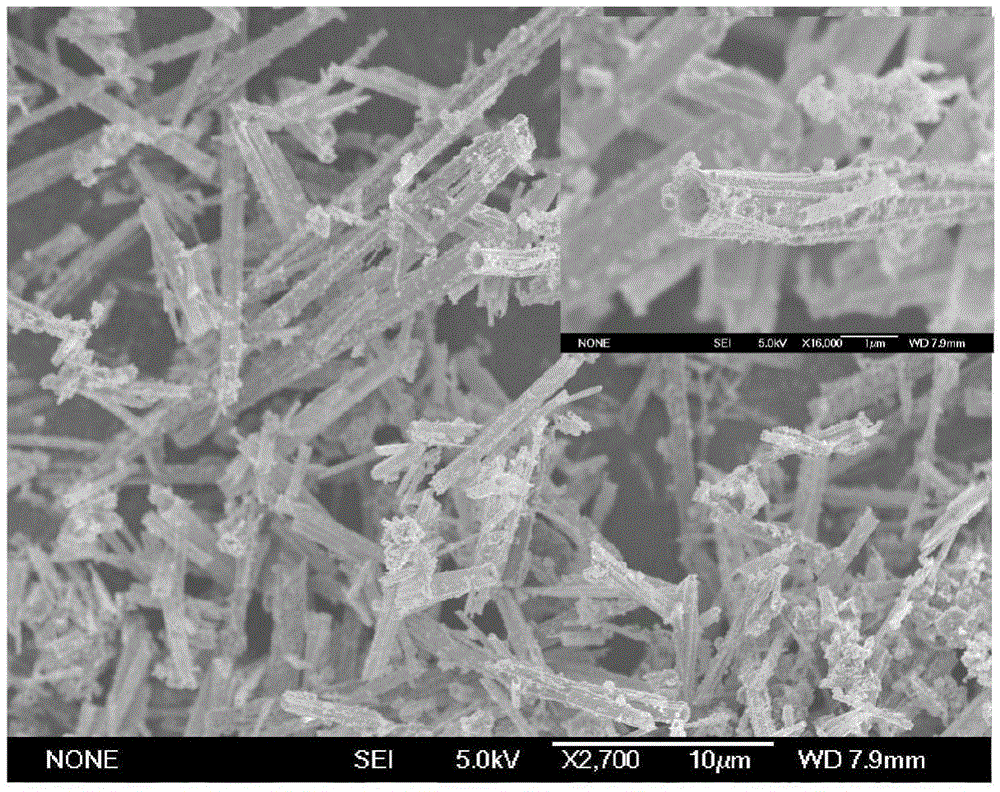

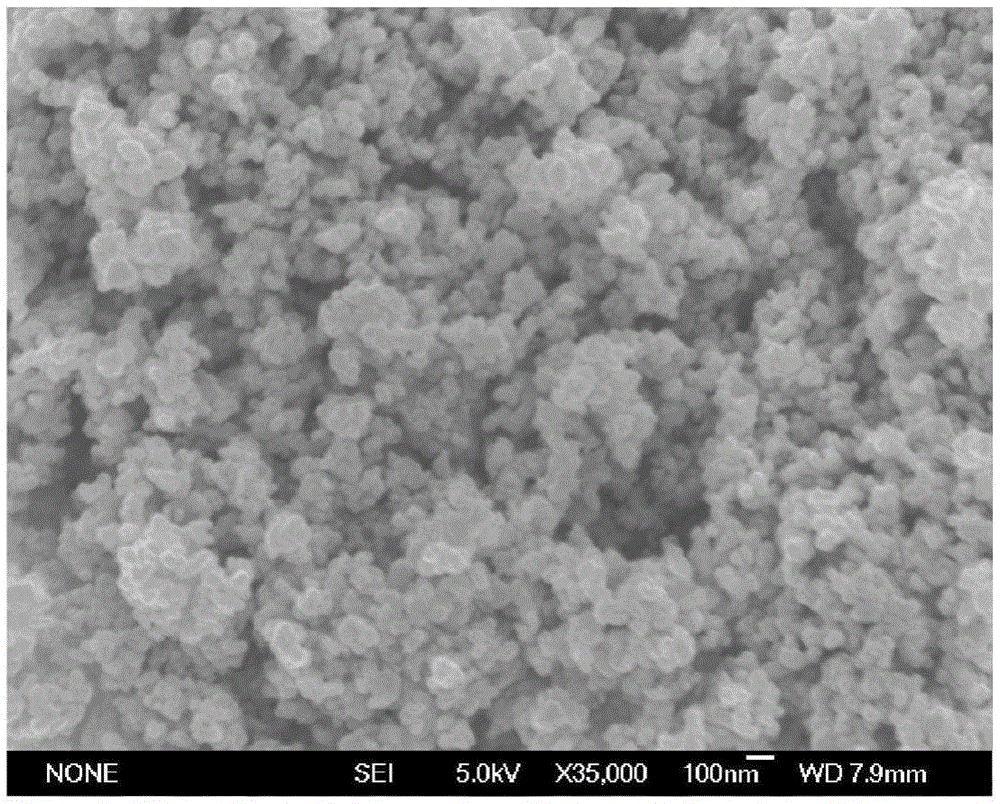

[0039] 0.1705gCuCl 2 2H 2 O was dissolved in 40 mL of double-distilled water to obtain solution A; 0.09 g of thioacetamide (TAA) and 0.04 g of NaOH were dissolved in 30 mL of double-distilled water to obtain solution B; the above solutions A and B were mixed under stirring, slowly Add 4mL PEG400 dropwise, the pH of the solution is 8.5, stir for 30min, transfer to a 100mL reactor, and react at 160°C for 6h; cool the reactor to room temperature, filter, wash three times with twice distilled water and ethanol, and dry at a constant temperature of 60°C Dry in the oven for 36 hours to obtain black copper sulfide microtube powder. Its X-ray diffraction pattern is as figure 1 (a), compared with the crystal standard card (JCPDS06-0464), it can be determined as a hexagonal crystal phase. The copper sulfide microtube has a diameter of 480-490nm and a length of 10μm.

Embodiment 2

[0045] The method for preparing CuS microtubes as described in Example 1, the difference is that the added TAA and NaOH are 0.083g and 0.043g respectively, the pH of the solution is 8.3; the amount of PEG400 is 3.5mL; react in a 150°C reactor 7h, CuS microtubes were prepared in a hexagonal crystal phase, with a diameter of 490-500 nm and a length of 9 μm.

[0046] The CuS microtubes prepared in Example 2 have an apparent reaction rate constant k=0.00836 / min for photocatalytic degradation of Rhodamine B; and an apparent reaction rate constant k=0.01013 / min for photocatalytic degradation of methyl orange.

Embodiment 3

[0048] The method for preparing CuS microtubes as described in Example 1, the difference is that the added TAA and NaOH are 0.09g and 0.048g respectively, the pH of the solution is 8.8; the amount of PEG400 is 4.5mL; react in a 170°C reactor 5h, the prepared CuS microtubes are in the hexagonal crystal phase, with a diameter of 485-495 nm and a length of 8 μm.

[0049] The CuS microtubes prepared in Example 2 have an apparent reaction rate constant k=0.00919 / min for photocatalytic degradation of rhodamine B; and an apparent reaction rate constant k=0.01009 / min for photocatalytic degradation of methyl orange.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com