Molybdenum sulfide/graphene/carbon nanoball composite material and preparing method thereof

A carbon nanosphere, composite material technology, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of poor electrical conductivity, the excellent performance of pure molybdenum sulfide cannot be fully utilized, etc., achieve high specific surface area, and ingenious experimental design. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, This embodiment includes the following steps:

[0029] (1) Add 500mg of glucose powder into 50mL of water, stir to obtain a uniform salt solution, transfer it to a hydrothermal kettle, and react at 180°C for 12h. After cooling down naturally, take out the precipitate and wash it repeatedly with deionized water for several times and drying to prepare carbon nanospheres;

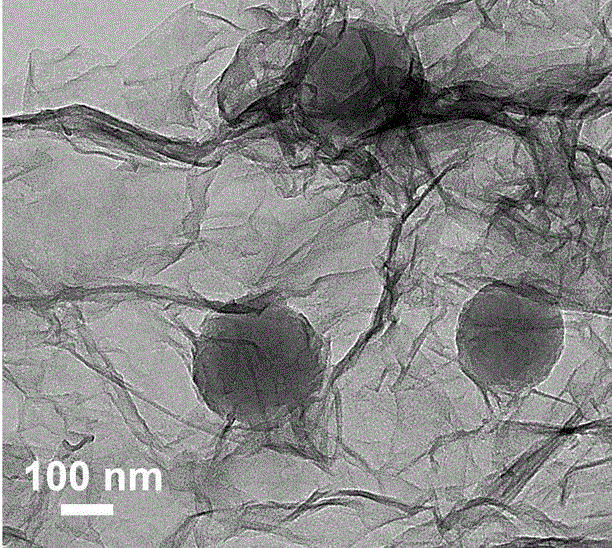

[0030] (2) Put the obtained 10mg of carbon nanospheres into 20mL of 1mgmL -1 After the graphene oxide solution, ultrasonic for 3 hours to prepare a uniform graphene oxide / carbon nanosphere dispersion;

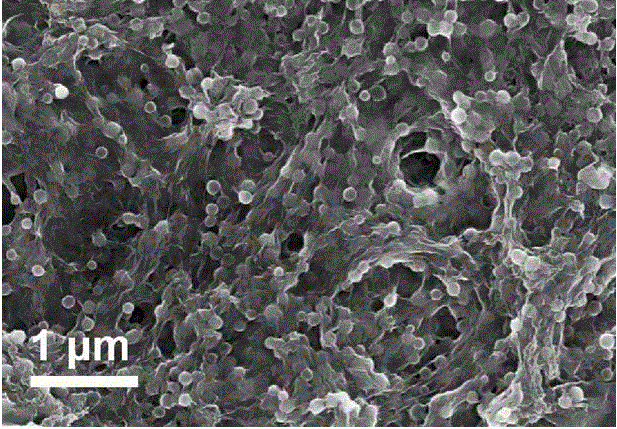

[0031] (3) Dissolve 100mg of ammonium molybdate and 75mg of thiourea in the graphene oxide / carbon nanosphere dispersion, transfer them to a hydrothermal kettle, and react at 200°C for 18 hours. After cooling down naturally, take out the precipitate and use it After repeated washing with ion water and drying, the molybdenum sulfide / graphene / carbon nanosphere composite material was prepared,...

Embodiment 2

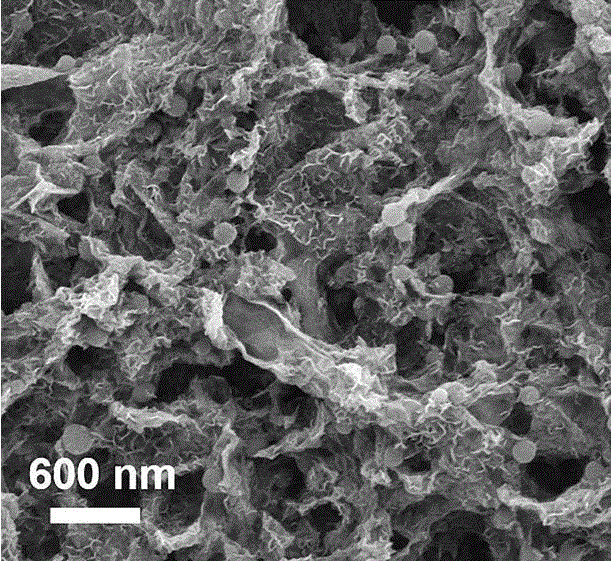

[0033] Example 2, Change the quality of ammonium molybdate in Example 1 to 50 mg, the quality of thiourea to 37.5 mg, and the rest are the same as in Example 1, and the finally obtained composite material is denoted as MoS 2 / GNS / CS-2. Implementation results: molybdenum sulfide nanosheets grow uniformly on graphene / carbon nanospheres; with MoS 2 / GNS / CS-1 compared to MoS 2 Molybdenum sulfide nanosheets in / GNS / CS-2 have smaller sheets and less content.

Embodiment 3

[0034] Example 3, Change the quality of ammonium molybdate in Example 1 to 200mg, and the quality of thiourea to 150mg, and the rest are the same as in Example 1. The composite material finally obtained is denoted as MoS 2 / CNF / G-3. Implementation results: molybdenum sulfide nanosheets grow uniformly on graphene / carbon nanospheres; with MoS 2 / GNS / CS-1 compared to MoS 2 Molybdenum sulfide nanosheets in / GNS / CS-3 have larger sheets and more content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com