Phosphorus aluminate fluorescent powder and preparation method thereof

An aluminophosphate and phosphor technology, applied in the field of phosphors, can solve the problems of less aluminophosphate phosphors, low luminous efficiency, and fewer types, and achieve excellent fluorescence performance, huge application prospects, high thermal stability and high thermal stability. The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Ba 2.90 AlPO 7 :0.10Eu 3+ Synthesis of phosphors.

[0031] Weigh 5.72 grams of barium carbonate, 0.51 grams of aluminum sesquioxide, 1.15 grams of diammonium hydrogen phosphate and 0.175 grams of europium trioxide according to the stoichiometric ratio, put the weighed raw materials in an agate jar, and grind the powder finely by grinding and mix well.

[0032] Then put the mixed raw materials in the corundum boat, in the high-temperature resistance furnace, under the air atmosphere, in the high-temperature tube furnace, heat to 1200°C at a heating rate of 100°C / hour, and keep at this temperature for 2 hours , followed by slow cooling to room temperature.

[0033] The powder obtained by sintering was ground into powder, washed three times with deionized water and ethanol to remove residual impurities, and dried at 200°C for 2 hours to obtain a luminescent powder with uniform particle size.

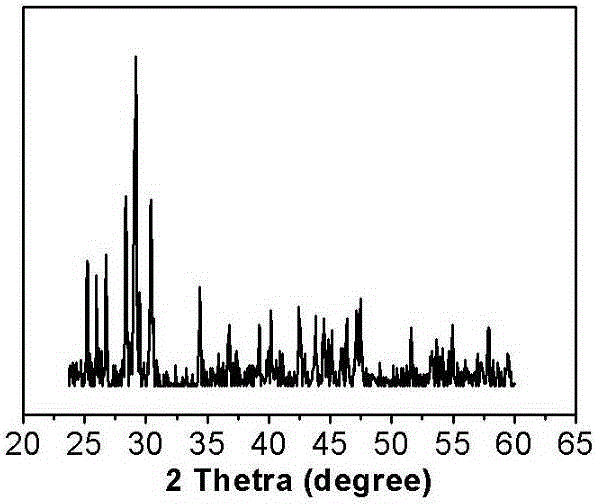

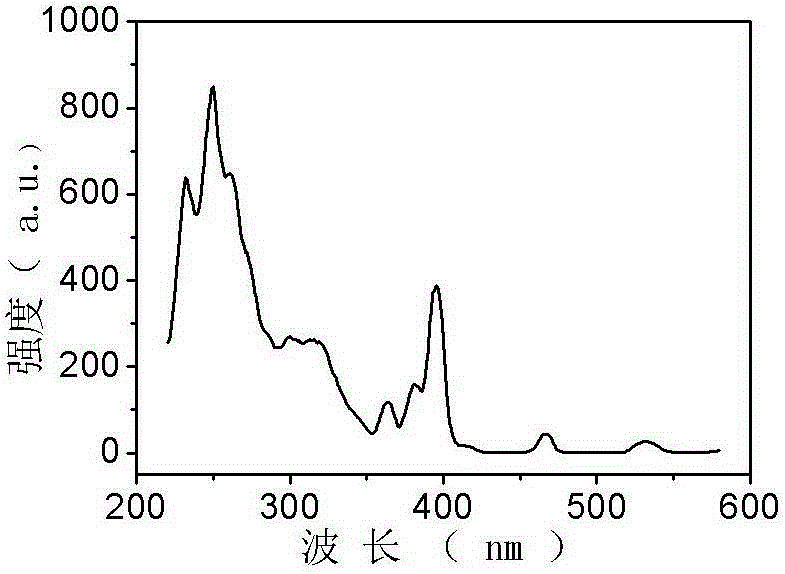

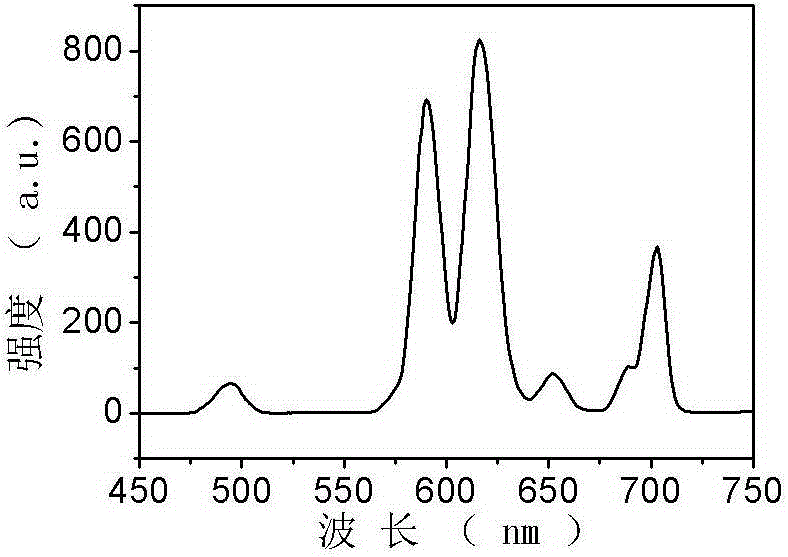

[0034] For prepared Ba 2.90 AlPO 7 :0.10Eu 3+ Phosphor powder, the inven...

Embodiment 2

[0036] CaSr 1.98 AlPO 7 :0.02Tb 3+ Phosphor Synthesis

[0037] Weigh 1.00 grams of calcium carbonate, 2.92 grams of strontium carbonate, 0.51 grams of aluminum oxide, 1.15 grams of diammonium hydrogen phosphate and 0.036 grams of terbium trioxide according to the stoichiometric ratio, put the weighed raw materials in an agate jar, and grind them Grind the powder finely and mix well.

[0038] Then put the mixed raw materials in the corundum boat, in the high-temperature resistance furnace, under the air atmosphere, in the high-temperature tube furnace, heat up to 1350°C at a heating rate of 300°C / hour, and keep at this temperature for 4 hours , followed by slow cooling to room temperature.

[0039]The powder obtained by sintering was ground into powder, washed three times with deionized water and ethanol to remove residual impurities, and dried at 150° C. for 2 hours to obtain a luminescent powder with uniform particle size.

Embodiment 3

[0041] Sr 2.98 AlPO 7 :0.02Dy 3+ Synthesis of phosphors.

[0042] Weigh 4.40 g of strontium carbonate, 0.51 g of aluminum oxide, 1.15 g of diammonium hydrogen phosphate, and 0.037 g of dysprosium trioxide according to the stoichiometric ratio, put the raw materials in an agate jar, and mix the powder evenly by grinding.

[0043] Then put the mixed raw materials in the corundum boat, in the high-temperature resistance furnace, under the air atmosphere, in the high-temperature tube furnace, heat up to 1400°C at a heating rate of 600°C / hour, and keep at this temperature for 6 hours , followed by slow cooling to room temperature.

[0044] The powder obtained by sintering was ground into powder, washed three times with deionized water and ethanol to remove residual impurities, and dried at 60°C for 20 hours to obtain a luminescent powder with uniform particle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com