Manufacturing technology of multi-effect multi-stage vortex tube cold-hot dual-energy machine system

A manufacturing process and vortex tube technology, applied in the field of new energy utilization, can solve the problems of unstable or large-scale operation, lack of practicability, and difficulty in entering mainstream energy equipment for large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

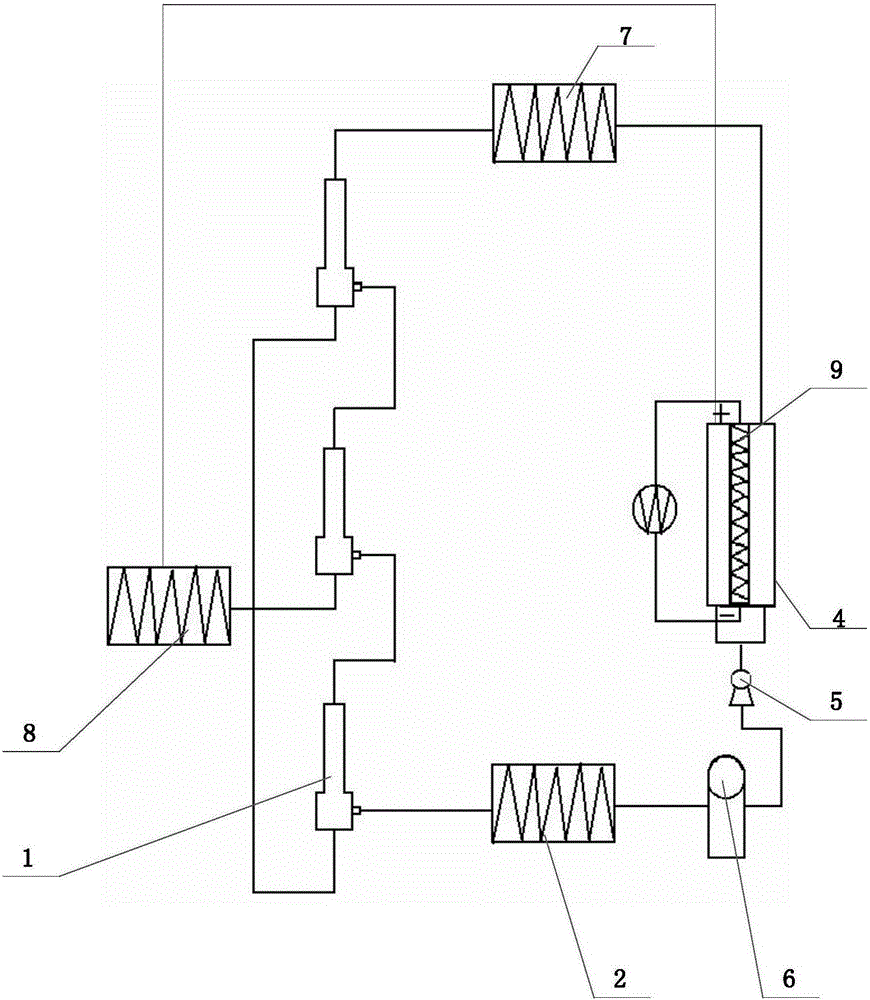

[0029] This embodiment is an embodiment in which heat energy is mainly used to provide a heat source. The vortex tube 1 is made of SUS304, and the intake flow is 40m 3 / min, 30m 3 / min, 20m 3 / min, the four vortex tubes are connected in multiple stages.

[0030] The basic energy-collecting evaporator 2 is made of aluminum alloy 7072 sunflower fin tubes. (Nominal pipe diameter DN × fin diameter × number of fins × tube wall thickness mm). The thermal conductivity of the material is 285W / m.k, the tube pressure is ≥3.8MPa, and the outer coating is selective (anodized) coating, the absorption rate of sunlight is ≥91%, and the infrared normal radiation emissivity is ≤10%.

[0031] The row spacing of fins is 200mm, and the energy-collecting area of 2 arrays of basic energy-collecting evaporators is 500 square meters. Select working fluid R134a, or R600, boiling point temperature: -26.1℃, critical temperature: 101.1℃, boiling point: -11.8℃, critical temperature: 134.98℃. The w...

Embodiment ( 2

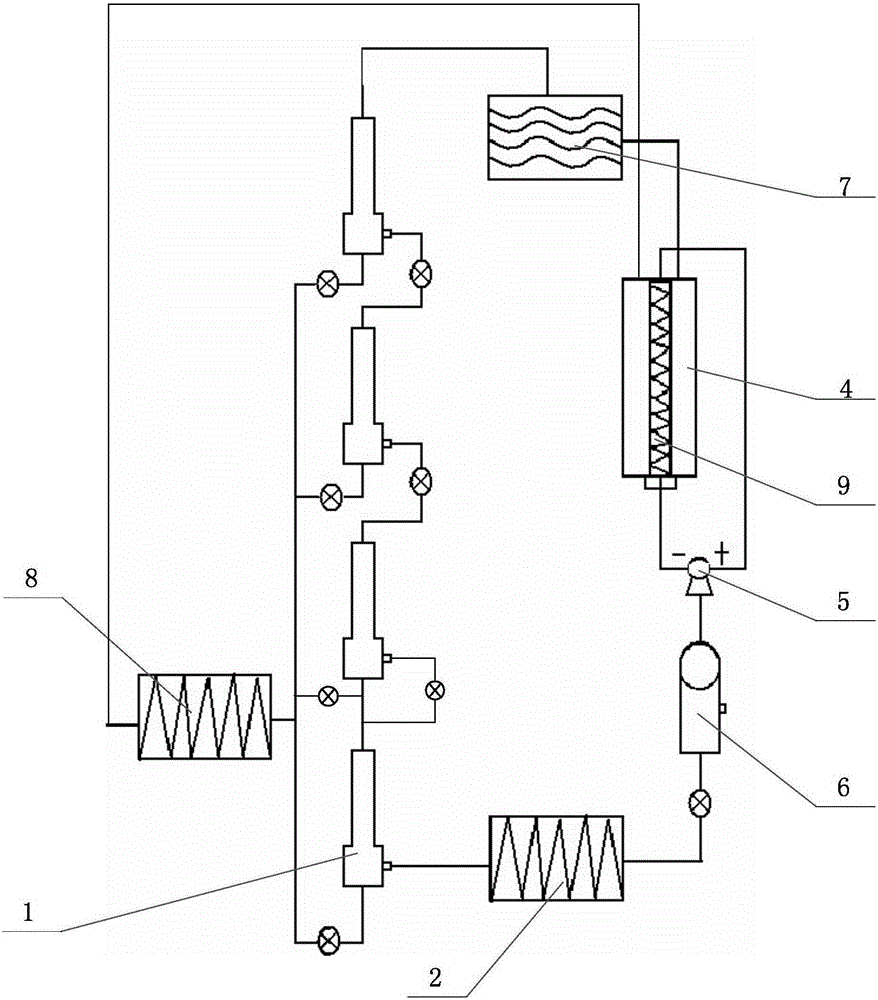

[0039] The high temperature working fluid gas at 325°C discharged from the fourth-stage hot end enters the heat exchanger load. After heat exchange (multi-stage heat exchange is possible), the reflux working fluid gas can be set at 100-50°C and enters the thermoelectric power generation mixer. The power generation temperature difference is controlled between 30 and 100 °C. After the cold and heat neutralization is carried out by the semiconductor crystal thermoelectric power generation plate, the working fluid gas (below the critical temperature) of 15-30 °C flowing out of the mixed flow tube is pressurized to ≥18 MPa by the compressor, liquefied into the working fluid tank, and a cycle is completed. .

Embodiment ( 3

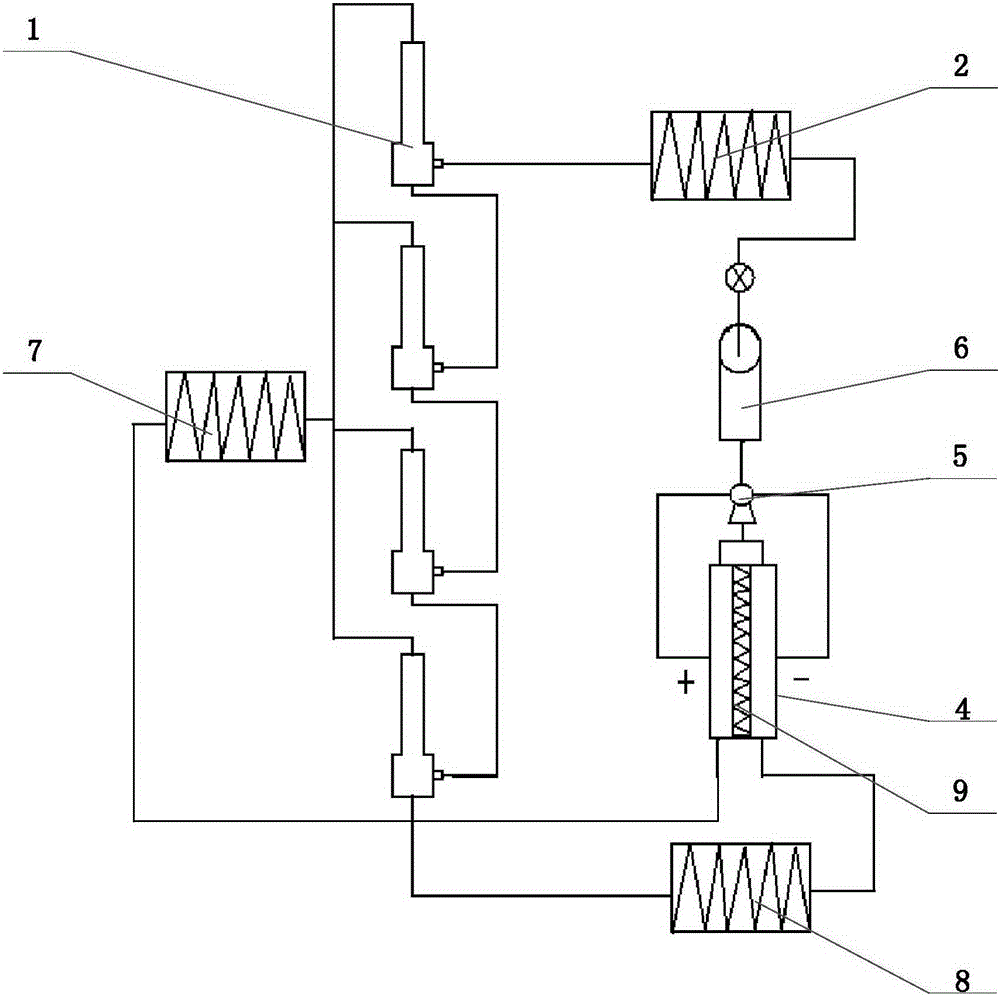

[0041] The low-temperature working medium gas at the cold end of the multi-stage vortex tube enters the air inlet of the next-stage vortex step by step, and finally achieves the cryogenic effect below -80 ℃, which meets the needs of quick freezing work. When cryogenic refrigeration, select the working fluid with ultra-low temperature boiling point, such as R170, R1150, R410A, etc. Since the boiling point of freon is generally ≤-40 °C, it will liquefy if it is lower than the boiling point. The liquid working medium flowing out of the solenoid valve at the outlet of the working medium tank enters the energy-collecting evaporator, and undergoes rapid phase change and vaporization through heat exchange with environmental energy (air energy, solar energy, etc.) The energy-carrying gas with the expansion and pressure increase of 3.0-5.0MPa rushes into the air inlet of the vortex tube, and is separated at a high speed by the vortex. The end outlet enters the air inlet of the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap