Adsorbent for deep removal of organic sulfide and preparation method and application thereof

A technology of adsorbent and sulfide, which is applied in the field of desulfurization, can solve the problems of complex process, deactivation of adsorbent, and decline of adsorbent performance, and achieve the effects of simple preparation process, increased specific surface area, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

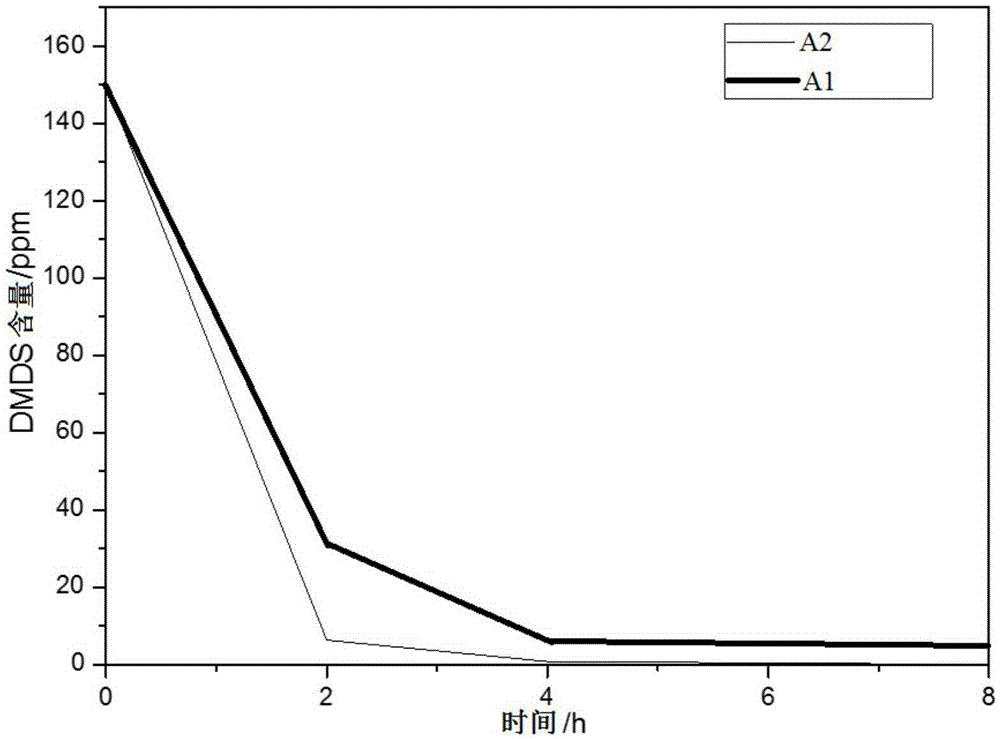

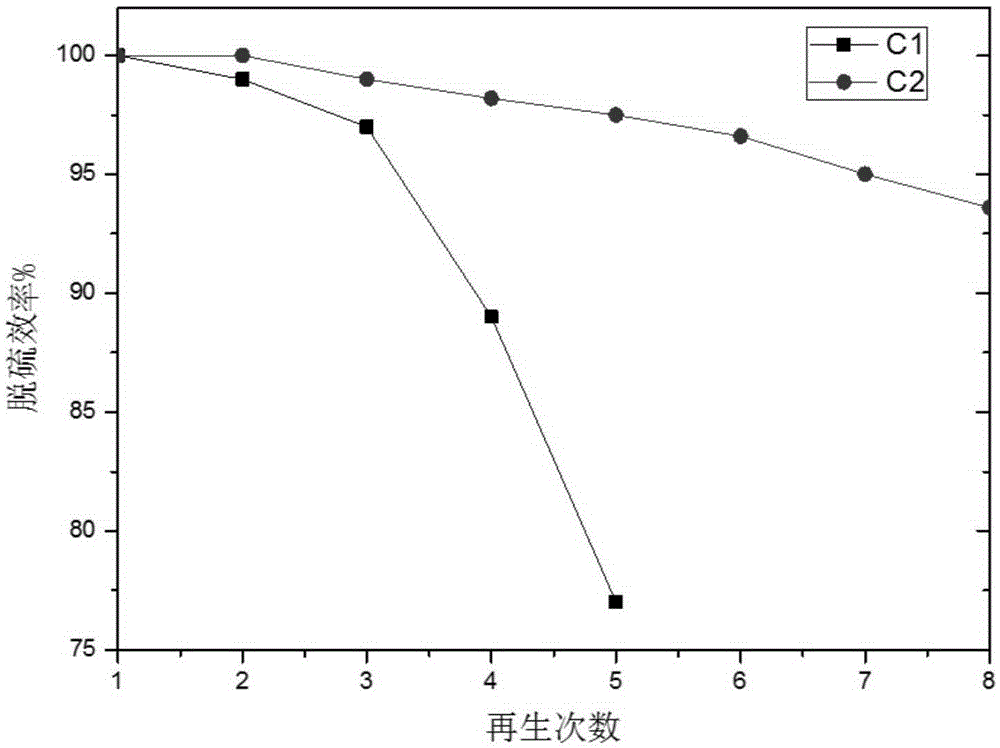

Embodiment 1

[0055] Preparation of acid-modified adsorbent: Weigh 100.0 g of 13X raw powder with a silicon-aluminum ratio of 2.2, mix it with 5.024 g of anhydrous acetic acid with a concentration of 5 mol / L, stir evenly, seal it and put it in an electric heating oven at 80°C, keep 8h. Weigh 5.037gCu(NO 3 ) 2 Dissolve in 44.057g of deionized water, and store the solution in the dark. Add 20.0g of kaolin and 2.215g of carboxymethyl cellulose to the acid-modified molecular sieve. After mixing evenly, pour the prepared copper nitrate aqueous solution. Material type, mechanical mixing 3h. After the raw materials are mixed evenly, a brown mixture is obtained. The humidity of the mixture should be slightly wet when rubbed with hands. The resulting mixture was extruded to obtain a strip-shaped material with a diameter of about 2 mm and a length of about 15 mm. The strip-shaped material obtained was transferred to a humid heat environment at 100° C. for aging for 24 hours. Finally, it was roa...

Embodiment 2

[0057] Preparation of acid-modified adsorbent: the preparation method is similar to that of Example 1, the precursor of the metal oxide active component used is silver nitrate, the calcination temperature is adjusted to 600° C., and the obtained adsorbent is designated as A2.

Embodiment 3

[0059] Conventional adsorbent preparation: compare the effect of acid treatment on molecular sieve specific surface, and prepare conventional 13X molecular sieve adsorbent. The specific implementation method is to weigh 13X raw powder with a silicon-aluminum ratio of 2.2, 25.0 g of kaolin, and 2.174 g of carboxymethyl fiber After the ingredients are mixed, add 45.022g of deionized water, after preliminary mixing, add the obtained raw materials to the mixing machine, and mechanically mix for 3 hours. After the raw materials are mixed evenly, a brown mixture is obtained. The humidity of the mixture should be slightly wet when rubbed with hands. The obtained mixed material is extruded into a strip to obtain a strip-shaped material with a diameter of about 2-2.4mm and a length distributed between 15-20mm. The strip-shaped material obtained was transferred to a humid heat environment at 100° C. for aging for 24 hours. Finally, it was calcined in a muffle furnace at 300°C for 5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com