Organic electroluminescent material and application thereof

An electroluminescent material and luminescent technology, applied in the field of materials, can solve problems such as poor film stability, and achieve the effects of excellent film stability, reduced turn-on voltage, and good film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

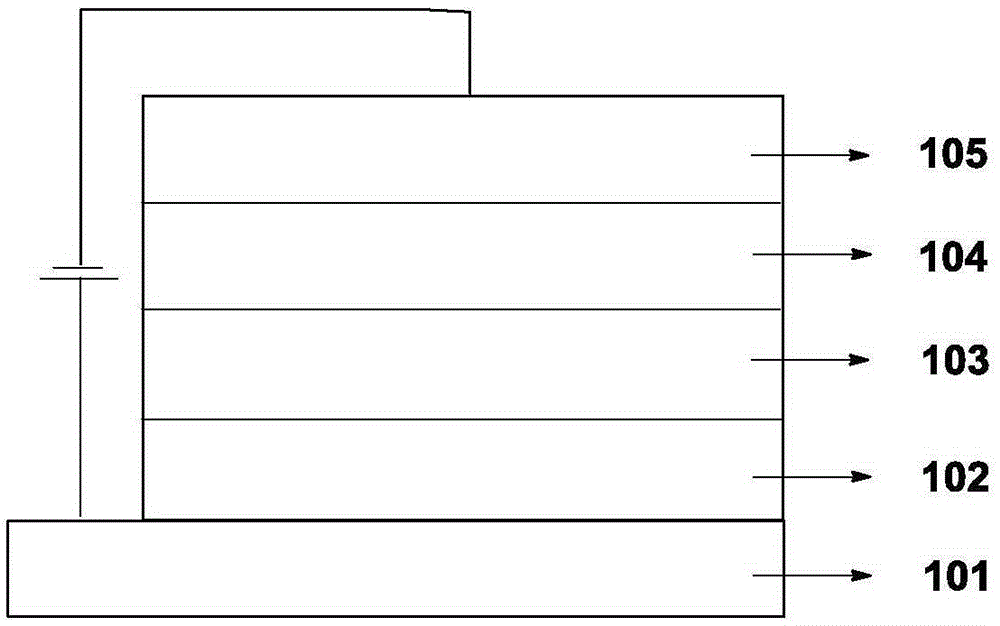

Image

Examples

preparation example Construction

[0029] The preparation method of the organic electroluminescent material in the present invention is as follows:

[0030] Taking the target C01 as an example, its synthesis route is shown in the following formula. The synthesis methods of other target compounds in the present invention are similar to the synthesis methods of C01. The specific synthesis methods are detailed in the following examples.

[0031]

[0032]

[0033] The present invention prepares the mentioned triarylamine small molecule organic electroluminescent material with spiro ring structure through the above method.

[0034] Preparation examples

[0035] The partial structure of the specific organic electroluminescent material synthesized in the present invention is as follows. For ease of reference below, the structural formulas of the above compounds are numerically subscripted and correspond to the compounds in the examples, for example, structural formula C01 corresponds to compound C01, structural formula C02 co...

Embodiment 1

[0042] Example 1 Preparation of compound 2 as an intermediate

[0043]

[0044] Preparation of compound 1: In a 2L three-necked flask equipped with a constant pressure dropping funnel, add magnesium metal (5.1g, 0.21mol), and dissolve 1-bromodibenzofuran (49.1g, 0.2mol) in 450g tetrahydrofuran, Place it in a constant pressure dropping funnel and use nitrogen protection. Heat the three-necked flask until the temperature in the bottle reaches 65°C. Add the 1-bromodibenzofuran solution in tetrahydrofuran through the constant pressure dropping funnel. Add 1-bromo at first One-fifth of the total amount of dibenzofuran in tetrahydrofuran solution, after the reaction is initiated, slowly drip the remaining part, and the dripping is completed for 1.5 hours, and react for 1 hour at the reflux temperature for use. Dissolve 2-bromofluorenone (51.8g, 0.2mol) in 220g tetrahydrofuran, then slowly pour it into the above three-necked flask, and react at reflux temperature for 3h. After the react...

Embodiment 2

[0047] Example 2 Preparation of Compound C01

[0048]

[0049] In a 100mL three-neck flask, add compound 2 (4.1g, 10mmol), N-phenyl-2-naphthylamine (2.63g, 12mmol), sodium tert-butoxide (1.92g, 20mmol), palladium acetate (0.01g, 0.04 mmol), tri-tert-butylphosphine (0.016g, 0.08mmol), mixed xylene (40mL), N 2 Protect, heat to reflux, keep the reaction for 8 hours, stop the reaction, cool to 25°C, add 30 mL of deionized water, stir for 5 minutes, separate the liquids, collect the organic phase, and remove the solvent to obtain the target C01 crude product, using silica gel column layer After purification, the eluent is cyclohexane:dichloromethane=2:1 (V / V) to obtain the crude product of the target product, which is recrystallized using absolute ethanol as the solvent to obtain the target product C01, 3.2 g of off-white solid. A chemical vapor deposition system was used for further sublimation purification at a sublimation temperature of 345° C. to obtain 2.8 g of compound C01 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com