Synthetic method of medical intermediate carbonyl-replacement aryl thioether compound

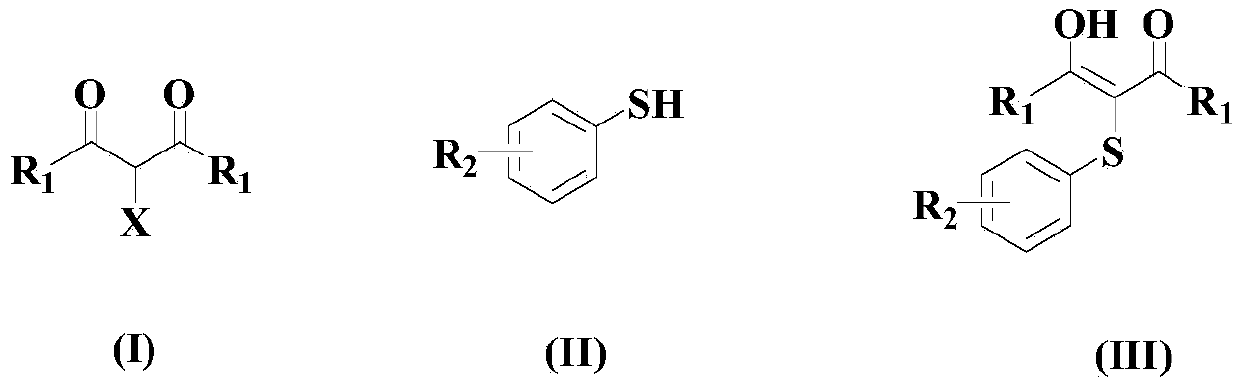

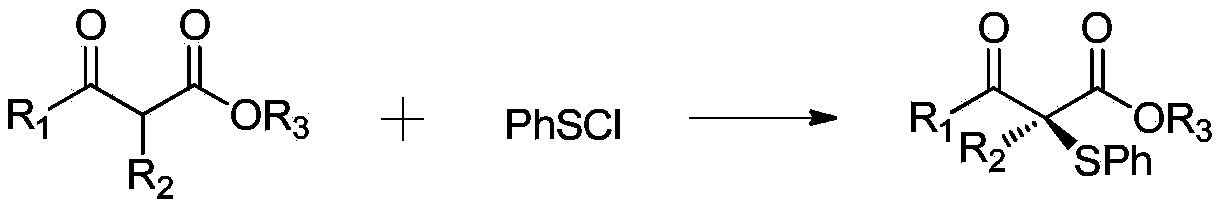

A synthesis method and technology of aryl sulfide, which is applied in the synthesis of sulfide compounds and the synthesis of carbonyl-substituted aryl sulfide compounds, can solve the problems of low reaction yield and reaction process to be optimized, and achieve broad market prospects, The effect of mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]

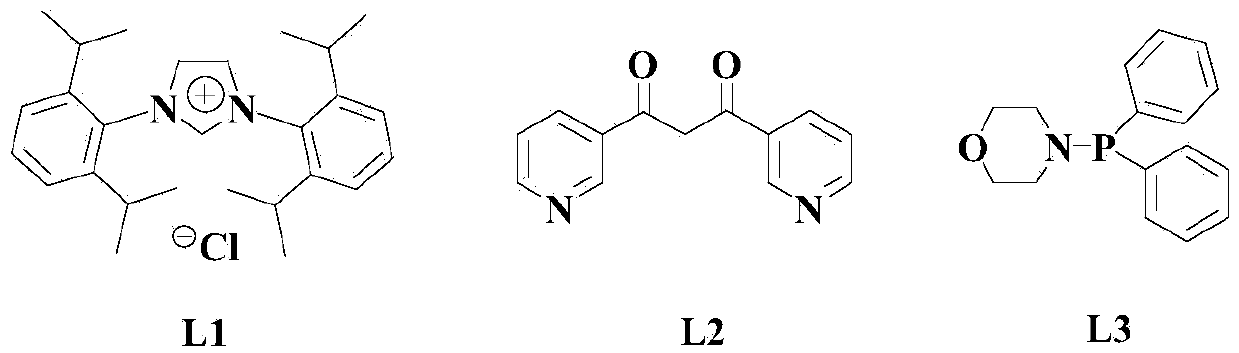

[0044] At room temperature and under a nitrogen atmosphere, to an appropriate amount of organic solvent (a mixture of chlorobenzene and DMSO with a volume ratio of 1:2), add 100mmol of the compound of the above formula (I), 140mmol of the compound of the above formula (II), and 10mmol of the catalyst (8mmolCu( PPh 3 ) 2 NO 3 With 2mmolNi(acac) 2 The mixture), 5mmol of organic ligand L1, 10mmol of activator p-methoxyphenyl tellurium oxide and 200mmol of basic cesium carbonate, then heated to 60°C, and stirred at this temperature for 8 hours;

[0045] After the reaction is completed, the reaction system is naturally cooled to room temperature, filtered, and 5% by mass hydrochloric acid aqueous solution is added to the filtrate, shaken thoroughly, and then ethyl acetate is added for extraction 2-3 times, and the organic phases are combined and decompressed. After distillation, the residue was subjected to 300-400 mesh silica gel column chromatography, and washed with acetone...

Embodiment 2

[0048]

[0049] Under room temperature and nitrogen atmosphere, to an appropriate amount of organic solvent (a mixture of chlorobenzene and DMSO with a volume ratio of 1:2), add 100mmol of the compound of the above formula (I), 170mmol of the compound of the above formula (II), and 12mmol of catalyst (8mmolCu( PPh 3 ) 2 NO 3 With 4mmolNi(acac) 2 ), 8mmol of organic ligand L1, 15mmol of activator p-methoxyphenyl tellurium oxide and 250mmol of basic cesium carbonate, then the temperature is raised to 75°C, and the reaction is stirred at this temperature for 6 hours;

[0050] After the reaction is completed, the reaction system is naturally cooled to room temperature, filtered, the filtrate is added to the filtrate with a 7% mass percent hydrochloric acid aqueous solution, fully shaken, and then ethyl acetate is added for extraction 2-3 times, and the organic phases are combined and decompressed After distillation, the residue was subjected to silica gel column chromatography of 300-...

Embodiment 3

[0053]

[0054] At room temperature and under a nitrogen atmosphere, to an appropriate amount of organic solvent (a mixture of chlorobenzene and DMSO with a volume ratio of 1:2), 100mmol of the compound of the above formula (I), 200mmol of the compound of the above formula (II), and 16mmol of the catalyst (12mmolCu( PPh 3 ) 2 NO 3 With 4mmolNi(acac) 2 ), 10mmol of organic ligand L1, 20mmol of activator p-methoxyphenyl tellurium oxide and 300mmol of basic cesium carbonate, then the temperature is raised to 90°C, and the reaction is stirred at this temperature for 5 hours;

[0055] After the reaction is completed, the reaction system is naturally cooled to room temperature, filtered, and a 10% aqueous hydrochloric acid solution is added to the filtrate, shaken thoroughly, and then ethyl acetate is added for extraction 2-3 times, and the organic phases are combined and decompressed After distillation, the residue was subjected to silica gel column chromatography of 300-400 mesh, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com