Light conversion agricultural film, and making method and application thereof

A light-transforming agricultural film and light-converting agent technology, which is applied in the field of agricultural light-light conversion functional materials, can solve the problems of poor absorption wavelength matching, slow light conversion intensity attenuation, short fluorescence life, etc., to reduce dust pollution and excellent luminescence Good performance and spectral matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

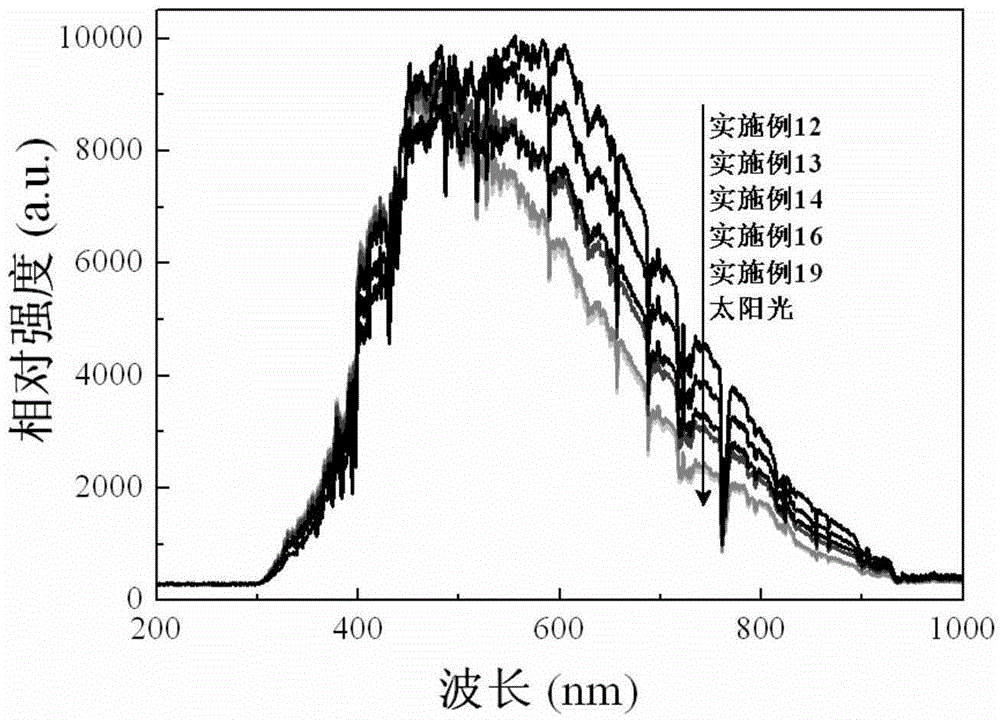

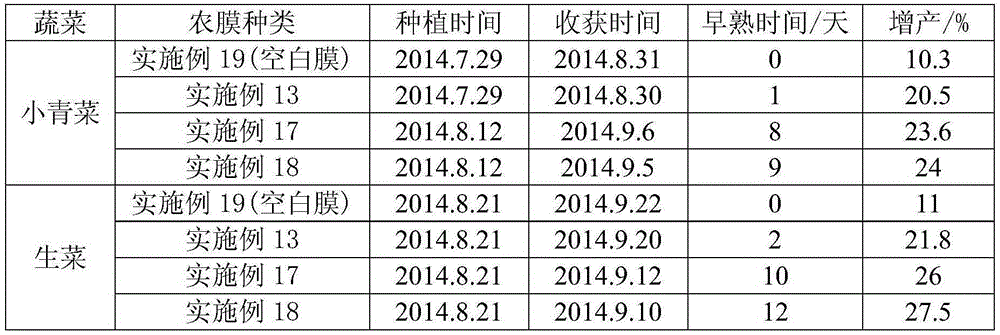

Examples

Embodiment 1

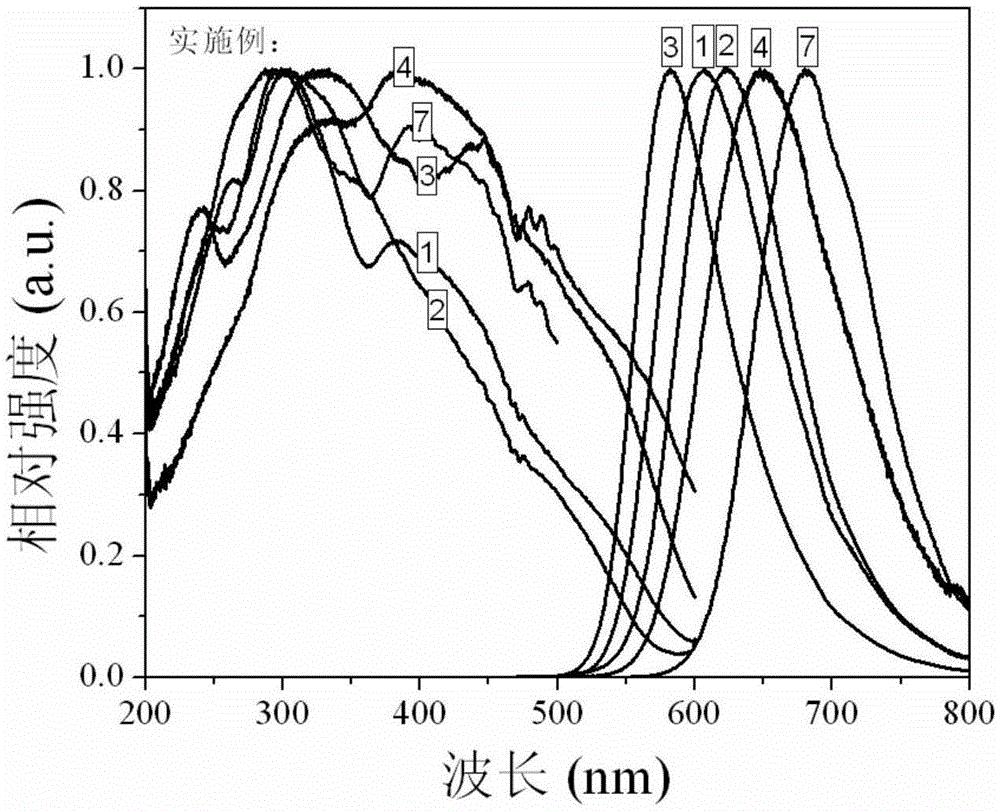

[0047] Embodiment 1: Nitride red light conversion agent Ca 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0048] According to the stoichiometric ratio, accurately weigh 1.96mol calcium powder, 5mol silicon powder, and 0.04mol europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °C. T...

Embodiment 2

[0049] Example 2: Nitride red light conversion agent Sr 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0050] According to the stoichiometric ratio, accurately weigh 1.96mol strontium powder, 5mol silicon powder, and 0.04mol europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °C. Th...

Embodiment 3

[0051] Example 3: Nitride red light conversion agent Ba 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0052] According to the stoichiometric ratio, accurately weigh 1.96mol of barium powder, 5mol of silicon powder, and 0.04mol of europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com